I am now into the inner workings of the clutches. American Hoist & Derrick Co. of St. Paul, Mn, (hereinafter referred to as AMHOIST), used hard maple blocks as friction material in these clutches, and according to their literature, these friction blocks almost never needed replacing. Sounds like a good choice of material. I'll try it.

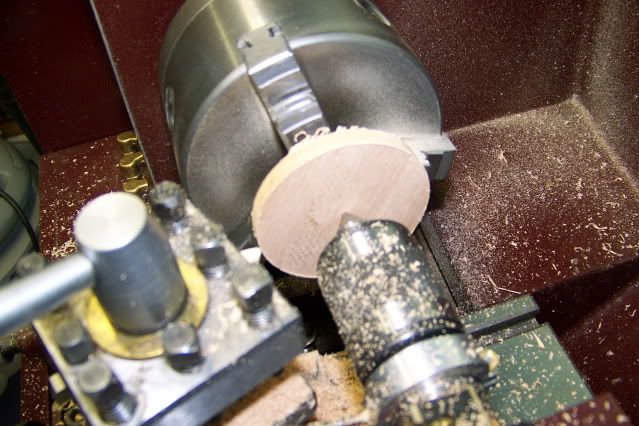

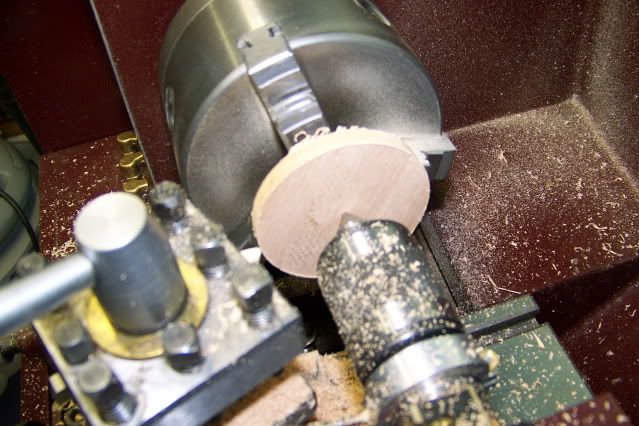

I don't have any maple handy and I'm not sure that it is the right thing anyway. It's a matter of scale. You can't buy an 1/10th scale maple. All the maple ever grown is from full size maple with full size cellular structure. There may have been 1/10th scale maple trees grown in the land of Lilliput, but I cannot find a website for Lilliputian Lumber so I will improvise. Maple is not available here, but Lowes has oak in a very convenient size (1/4" x 2 1/2" x 24" ) so that's where I'll start. Carefully selecting a piece with vertical grain to minimize cupping, I hacked it into little squares with my hacksaw and pressed it against the lathe chuck face with the live center, just like making a flywheel disk out of aluminum brass.

Oak is very hard and machines easily. The swarf is soft and fluffy and fills up the chip tray pretty quick but the method worked very well. I have spent a LOT!! of time in front of a wood lathe and would never have done it that way before. I was a little concerned that to much pressure with the live center point might split the wood. A proper woodworking approach would use a live cup center but I had no problem at all. The cutting force is so much less that I didn't even need to use double sided tape or anything between the wood and the face of the chuck jaws. Just pressed it up firm with the tailstock.

I used a very sharp HSS bit and it left a nice cut on the edge of the oak. If I were going to apply any type of finish, I might touch it with a little sandpaper but this is going to be a friction face so I burnished it to a hard finish by pressing another piece of wood against it while turning in the lathe.

The disk was then gripped with the outside jaws and the center was bored to 3/4" ID to clear the hub. I made a few extras. Who knows what will happen?

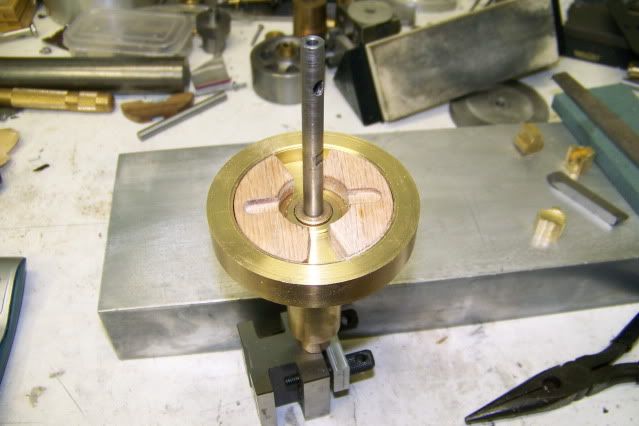

It looks like I am making a friction pad that will make face contact but I am actually making two pads that will expand radially and make contact on the edges. The pads need to have the same radius as the ID of the clutch drum so it starts out as one disk that fits inside the clutch:

And then gets cut into two separate shoes. Before it gets cut, I transferred it to the mill and cut to dead end slots, .15" deep, at 180 degrees apart.

These slots will be the only connection between the shoes and the actuator plates on the drive gear. I don't know if this will work. I don't want to use adhesive and I cannot figure a good way to use a fastener. I want the shoe to have a sort of floating ability so that outward pressure will seat it against the clutch drum. I had nightmare visions of a loose screw floating around it the works and wreaking havoc, so no screws

Here are the shoes in the clutch drum:

Here are the actuator plates sitting in the slots for visualization only. They will actually sit in slots in the gear and protrude into slots in the shoes.

This is the back side of the gear with the protruding plates.

The shoes will be flipped over and the slots and the protrusions will match up looking like this

Then the whole thing goes together like this:

In the above pic, downward pressure on the crossbar forces the actuator plates outward through small links that are barely visible. You can refer to an illustration in a previous post for a better view.

Here is my problem! The length of these link bars is critical to getting equal pressure and movement to the shoes. The AMHOIST prototype uses a threaded bar for this adjustment link but that is out of the question in 1/10th scale.

I don't think I have the answer.

Your comments and suggestions are solicited! I need to get a grip on this. Otherwise my commitment to posting a video of the donkey running by the end of next week is in jeopardy!

Jerry