I think I got a lot done today so this might be a long post. If it gets to be too big, I'll break it into 2 or more bits.

Starting with the hunk of brass above, 3" x 1/2" x 12", I hacksawed it into 4 pieces 2.7" x 2.7" x 2.7" x 2.7" (thats 8 sides). Much easier than sawing aluminum.

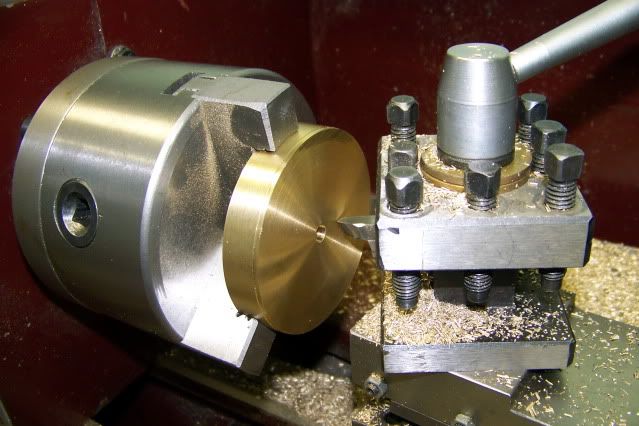

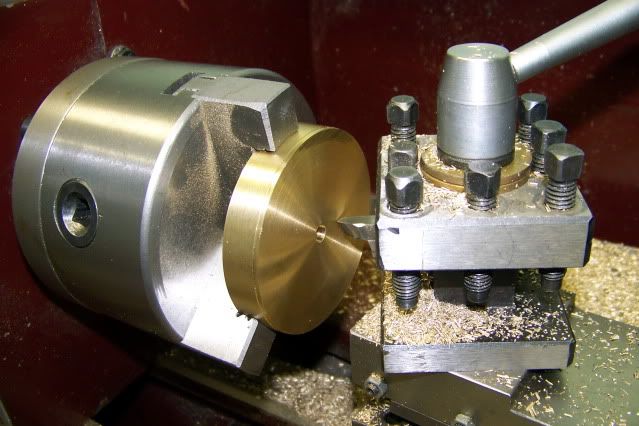

Then, using Bogs' flywheel method, I turned it into 4 disks 2.6" diameter.

Then gripping each in the 3 jaw, faced one side, flipped it around and faced the other side and then drilled and reamed a 1/4" hole for mounting on a mandrel.

I then mounted each on the mandrel and took a final cut to bring it to 2.58" (OD for the gear).

Then I setup the rotary table for cutting the gears. First centered a 1/4" shaft in the 4 jaw and checked that it aligned with the "X" axis. There are keys on the bottom of the rotab for this but I had never verified the alignment so I checked. Turns out the keys were good enough.

Then I centered the mandrel in the 4 jaw and mounted one of the gear blanks, and checked again. Good enough.

I then checked the single point cutter that I had used on the trial aluminum gear. The edges seemed sharp but I decided to dress them with a stone before starting. Mounted the holder and set the tip of the bit on center. I tightedened the "Z" lock, set the depth stop for added security, checked and tightened the "Y" axis clamp, checked and tightened the Rotab hold down clamps and then checked everything one more time. I think I was stalling. Once the first tooth is started, you're committed. I had experience a little "bit creep" previously so before starting, I decided to make a height guage.

I'm called for dinner: I'm back, edited above to add pics.

The height guage is a piece of 1/4" tool steel held in a v-block and set to just touch the bottom of the bit. I can use it periodically to be aware of changes in the bit height.

Nothing left to do but get on with it. Taking full cuts at 2500 RPM, the brass cuts nicely. I cut a few teeth and used the guage to check the height. All is good.

To cut the full 1/2" gear face takes 16 turns on the "X" crank. I'm a little tentative at first but its better to keep the feed steady and full. I find that I can take about 2 rotations per second of feed without complaint from the machinery. By mentally counting, "one (turn) chimpanzee (turn) two (turn) chimpanzee (turn), I can keep an even feed rate and keep my thoughts from wandering.

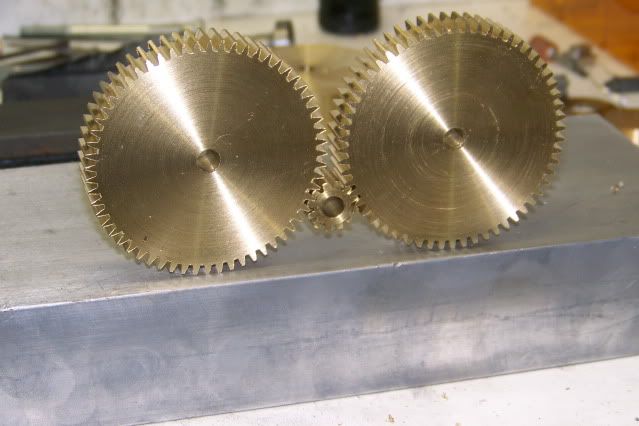

All goes well and in a little over an hour I have 60 teeth on the gear.

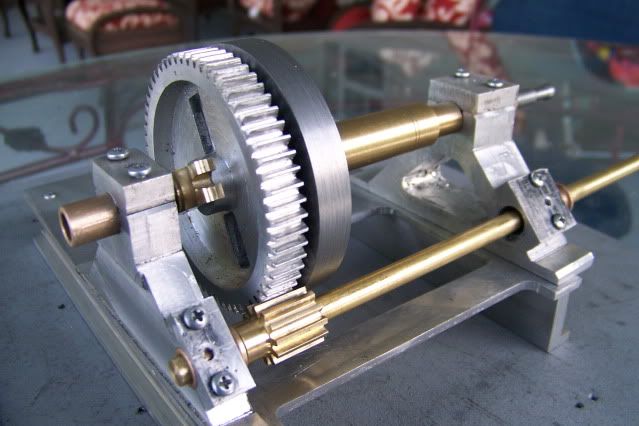

It meshes with the pinion and I feeling confident so on to gear # 2.

I think Ive got the technique down pretty solid so I'm going to try to work straight through it. Starting time:

Finish time:

40 minutes from start to finish, 1.5 teeth per minute. I could do this all day.

Two gears and pinion mesh nicely.

Both gears now must be trepanned (I learned this word here, hope I'm using it right. The cut should be 3/8" deep, leaving a 1/8" web between the hub and rim. Hub diameter .75", rim ID 2". Flat bottom, square corners. I'm going to use the same tool that I turned and faced the blank with. HSS, 80 degree pointed, no rake, flat on top, sharp and polished. The tool holder is oriented so that the tool is pointed toward the front of the lathe, with the one edge 5 degrees off of the face and the other edge 5 degrees off of parallel with the axis. It is positioned on the far side of the lathe axis:

To set the final depth, the compound slide is advanced to the limit of its travel. The carriage is moved up until the cutter touches the face and locked. The compound is then backed off of the face by 3/8". The carriage is then unlocked and moved up until the cutter again touches the face and LOCKED! I can now adjust the depth of cut using the compound and know that I will not exceed the final depth. When it reaches the end of its travel, the depth of cut will be 3/8".

I'm going to take the first cut on the far side of the lathe axis with the lathe running in reverse. My threaded chuck mounting has a clamp that prevents it coming of in reverse. The first cut begins just beyond the hub diameter to a depth of about .025" and proceeds across the face of the gear towards the far edge, stopping before the cut reaches the rim ID point.

Five or six cuts of this depth are made across the face before the cutter is withdrawn from the hole and moved forward to the front edge of the rim just short of the rim ID point. Now with the lathe turning in the normal forward direction, facing cuts are made across the blank.

I hope this is clear because I seem to have lost the pics! Sorry. I can try to get some more tomorrow if anyone needs them. I continue working this way, occasionally shifting from font to back, forward to reverse, until I reach the end of the compound travel. I am at the bottom of the cut. The carriage is still locked. I can now take a penetrating cut at the rim ID and face toward the hub, leaving a square corner. Then I shift to the back and make a penetrating cut at the hub and face off towards the rim (at the back) leaving a square corner and the bottom of the cut is dead flat.

You can see the result in this pic:

Here is another finger power video to show both gears in mesh:

Leaving the carriage locked, I can take the part out of the chuck and replace it with gear #2 and do the same thing to it with identical results. Before taking the gear out of the chuck, I take several facing cuts across the hub, reducing its thickness by .25" below the face of the gear. This is to make room for the clutch mechanism.

The same type of trepanning cut must be made across the face of the clutch/brake drum blanks to make room for the internal expanding clutch friction shoes.

Ill get some shop time tomorrow but no time for evening report. Wife is taking me to a concert.

Jerry