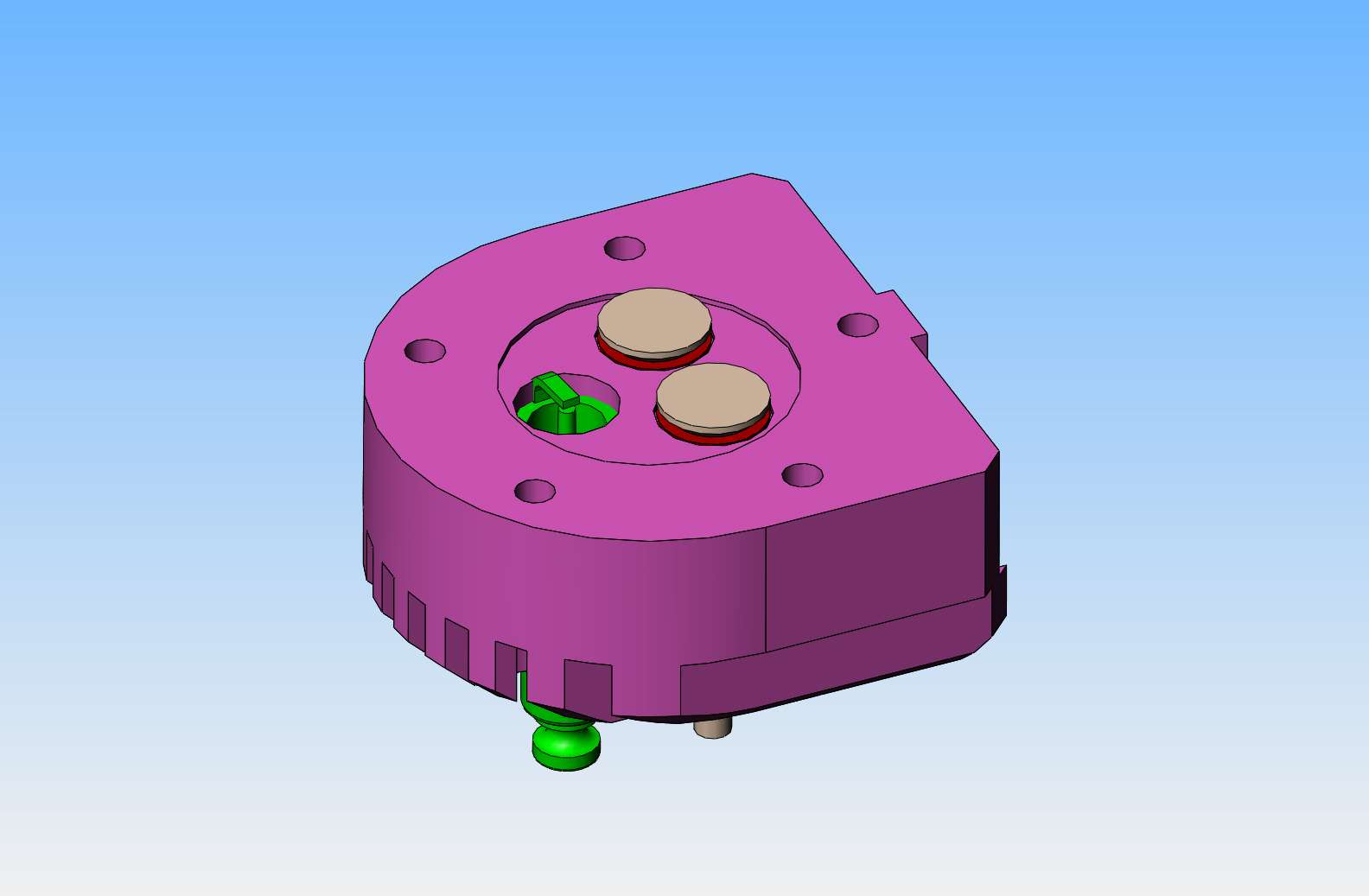

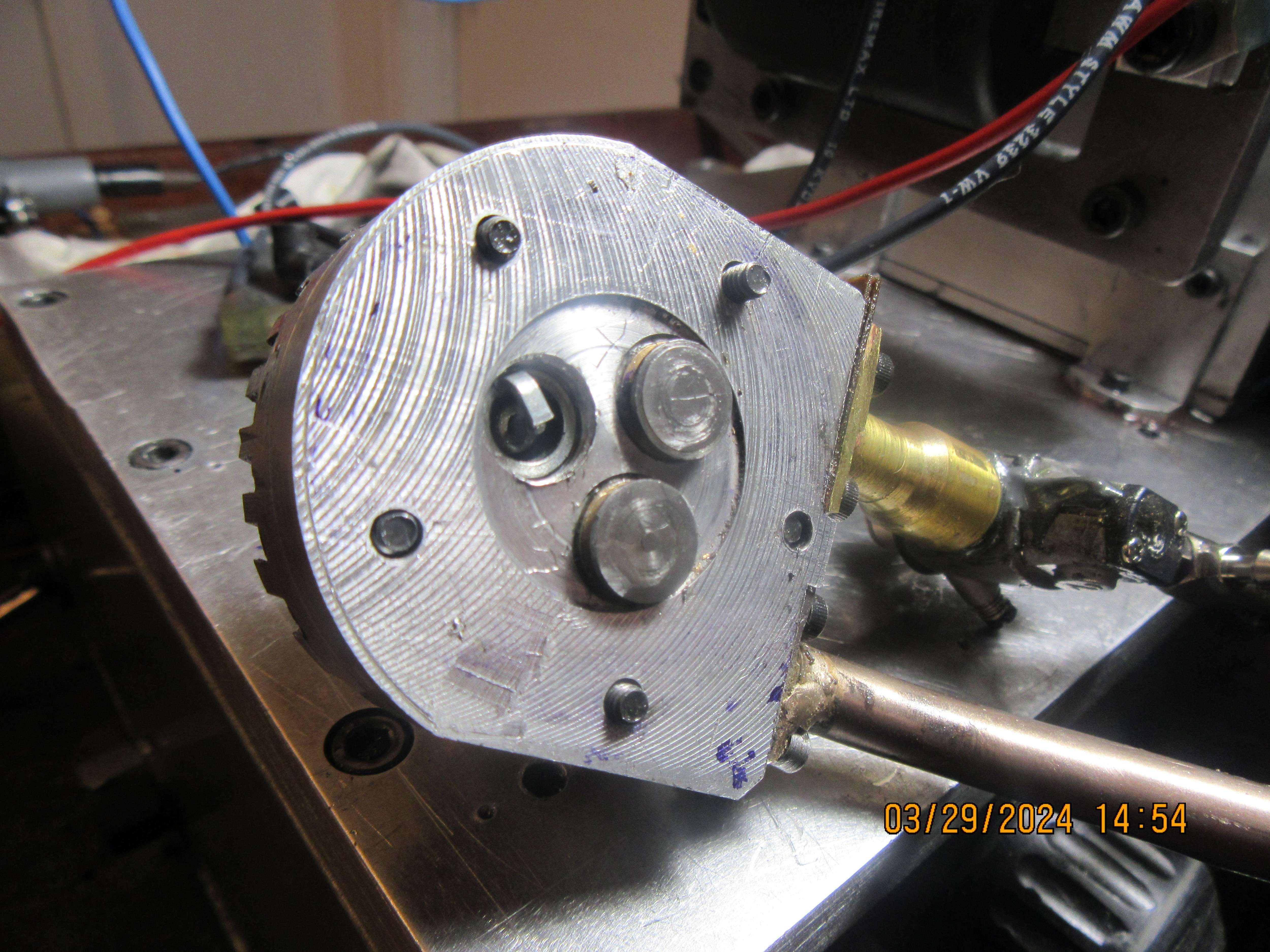

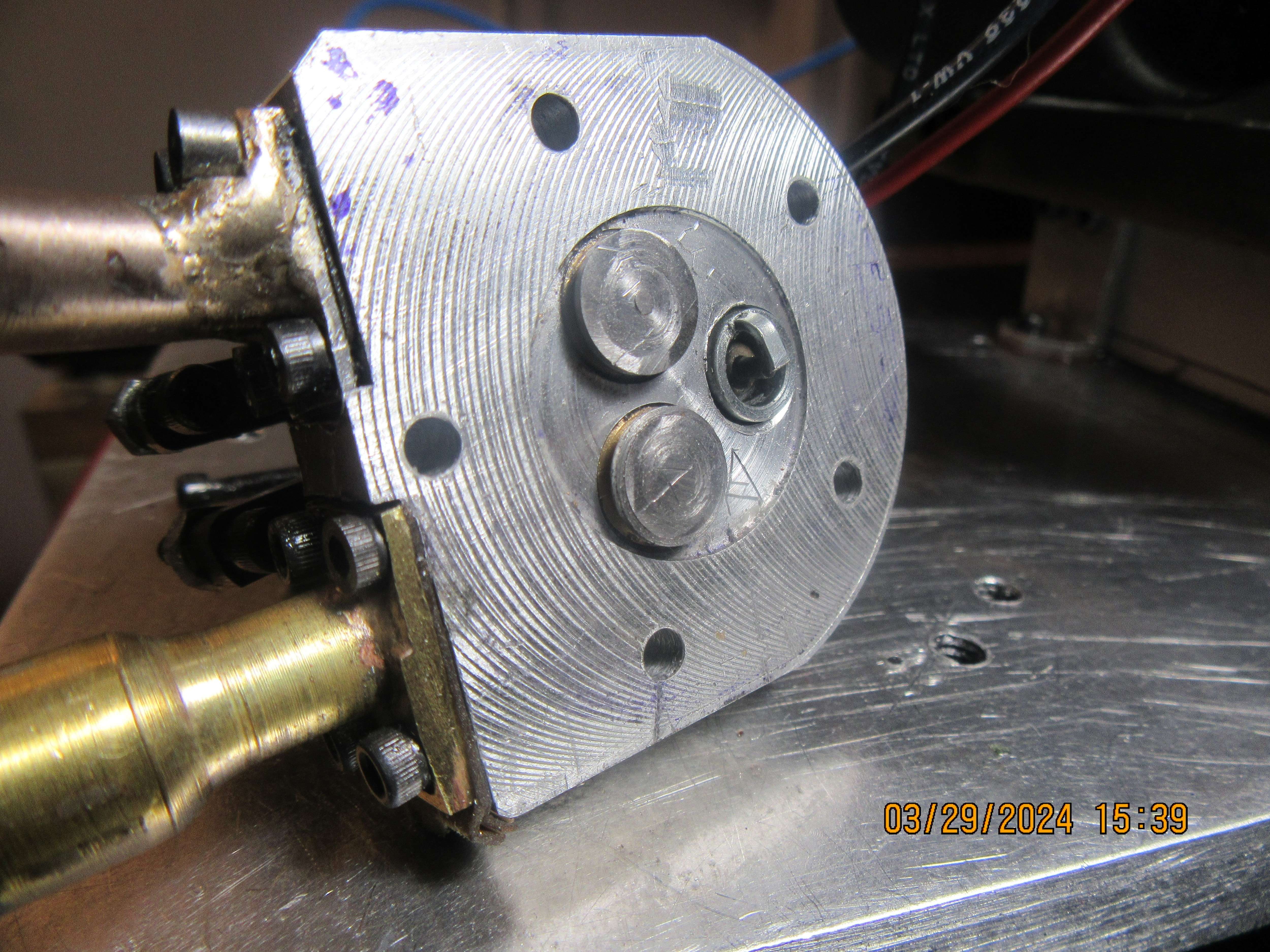

In review, let's see what I have done here. I used Malcolm Stride's Bobcat engine as a design layout. Did I build Malcolm's engine?--No. My stroke is different. My bore is different. My ignition is different. My carburation is different. My main engine block is different. However, it is the same overall layout as Malcolm used. I had problems sourcing a coil with dual outputs, so I "borrowed" a double output coil from a project I built a few years ago. I had originally used a single carburetor with an intake manifold that spanned between two cylinders, but I had problems getting it to seal properly against both cylinders, so I replaced it with two separate intake manifolds and switched up to two separate carburetors. The engine wouldn't run with the original curved flank cams that I had machined, so I switched over to straight faced cams. George Britnel, who in my estimation is THE Engine God, has said that on these small engines, the cams don't really need curved flanks, so I remade the cams with straight flanks. When I originally designed this engine, I knew that the valves would interfere with the pistons if the engine "jumped Time" --A valve would hit the piston at top dead center. So---I machined a 1/8" thick spacer to set between the cylinders and the crankcase to avoid that collision. This did ensure that there was no collision between piston and valve, but it also lowered the engine compression considerably and I couldn't get the engine to fire. Yesterday, I removed the spacers from under the cylinders, and although the piston does get very close to the valve, it doesn't touch them during a full engine revolution. So---This engine is a prototype. No one has ever built this engine before. Do prototype engines ever run as soon as they are finished-----very rarely. Some do, but the majority of them don't---not without a lot of design tweaking and mechanical changes. Today it has been three months since I began the design of this engine. Am I tired of working on it?---Yes. will I keep tweaking the design until it runs?--Well yes, I certainly hope so.-----Brian