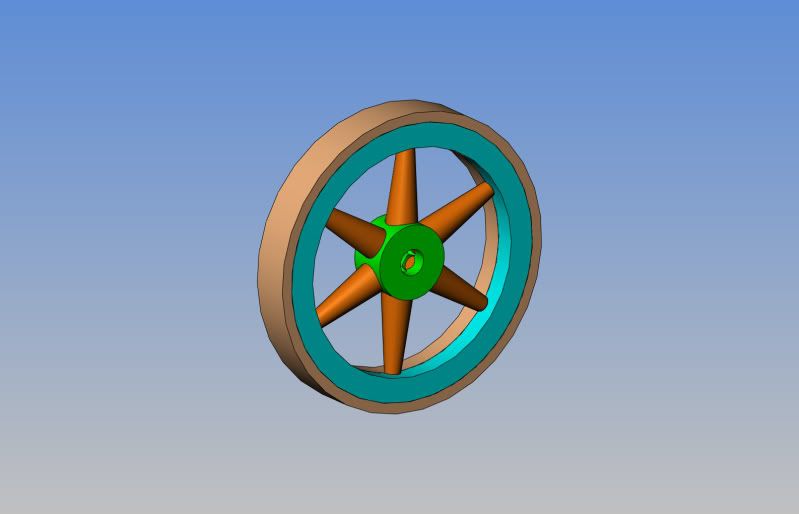

Gentlemen--We have a runner!!! I spent the day fitting my pile of Popcorn parts together, and a long, tedious day it was. Both my 10-24 die and my 5-40 die were so dull that I had to buy new ones and rethread everything. Then I managed to break the 1/8" dia. control rod off flush with the surface of the eccentric strap. However, luck was with me and I was able to drill it out, rethread, and save the part. When I set the cam I followed Elmer Verburgs instuctions---Set the piston at either top or bottom dead center, and set the valve exactly in the center of its travel. After assembly, the engine was very stiff, but after an hour of "running in" with my electric drill motor, it freed up considerably. I wanted badly to try the engine out, but haven't yet built a flywheel for it, so I robbed a flywheel off of the Chucks Hit and Miss Air Engine that I built two or three years ago, as it was close to the right diameter and width. I had to open the bore up from 1/4" to 5/16" and machine about .040" off the width. I plugged the air in and opened the valve, and to my great pleasure the engine started immediately and has been running in my basement for the last two hours. I will be building a "fancy" flywheel for it, but that will be sometime in the next two weeks. I'm posting this from my wifes laptop computer, because my big computer is temporarily across town at an industrial plant where I am working a temporary engineering/design contract.