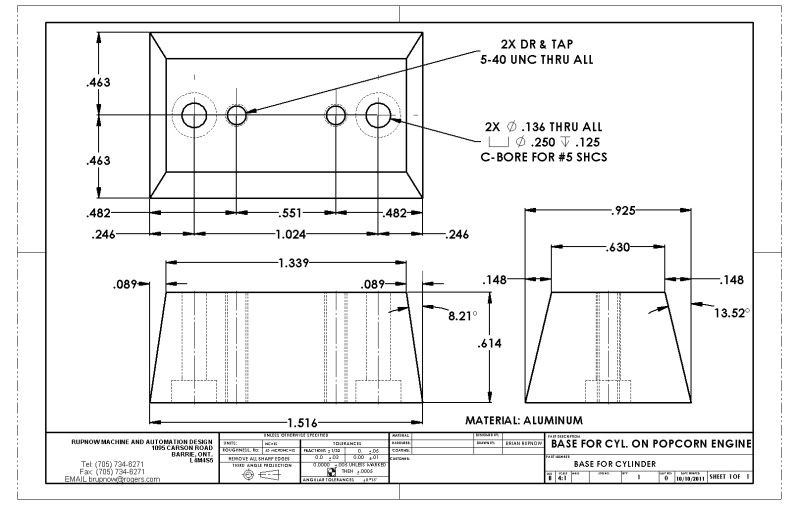

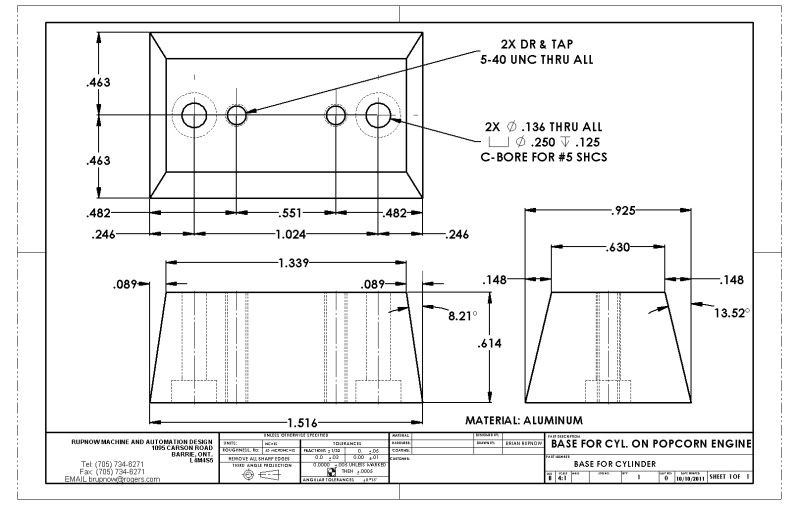

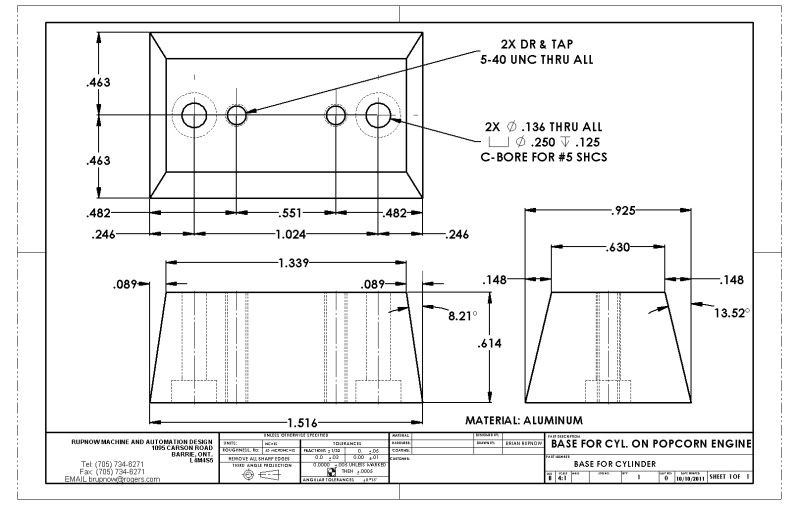

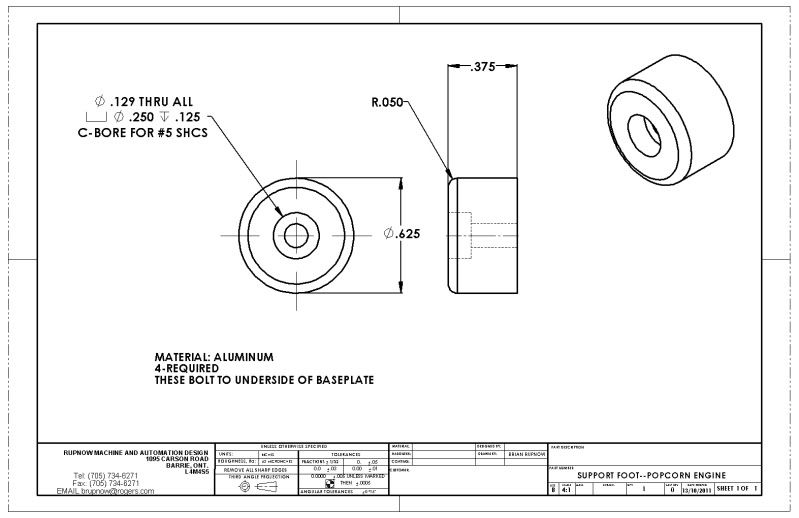

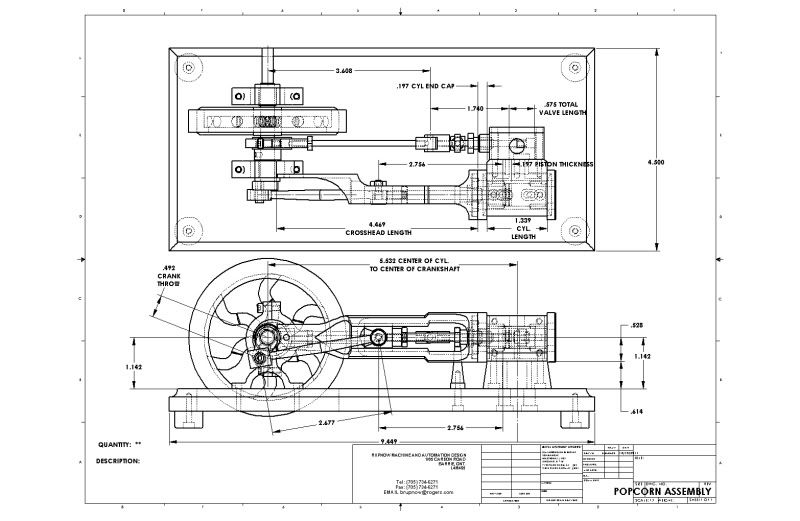

And last but not least, the support that the cylinder sets on. Its kinda tricky, because there is an angle on all four sides.

sbwhart said:Great set of drawing Brian:- I've PM you about them

I don't know how your planning to do the cross head guide but if you're going to use the fixed steady method i used just a word of warning, check out the steady that it bolts down secure to the lathe bed, the steady that was suplied with my Chines lathe was a load of crap as suplied, in fact I would say it would have been dangerouse to use. I modified mine by bolting a chunk of ally across the base to make a wider more positive base with tapered pull ups, that fixed it securly to the lathe bed, can't post pictures of it at the moment.

Stew

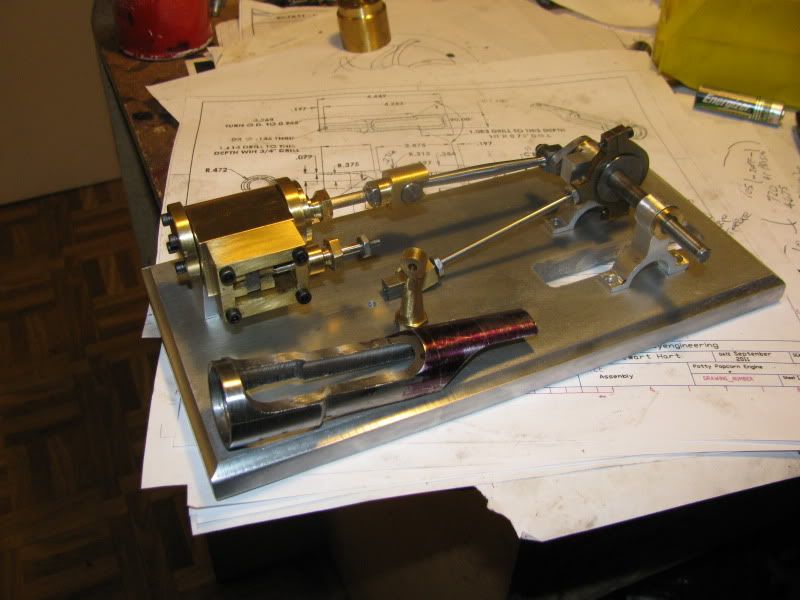

kvom said:In looking at the plans, it seemed to me that the valve gland could be lengthened enough so that the little support piece wouldn't be needed, and then getting the support's height exactly would no longer be a problem.

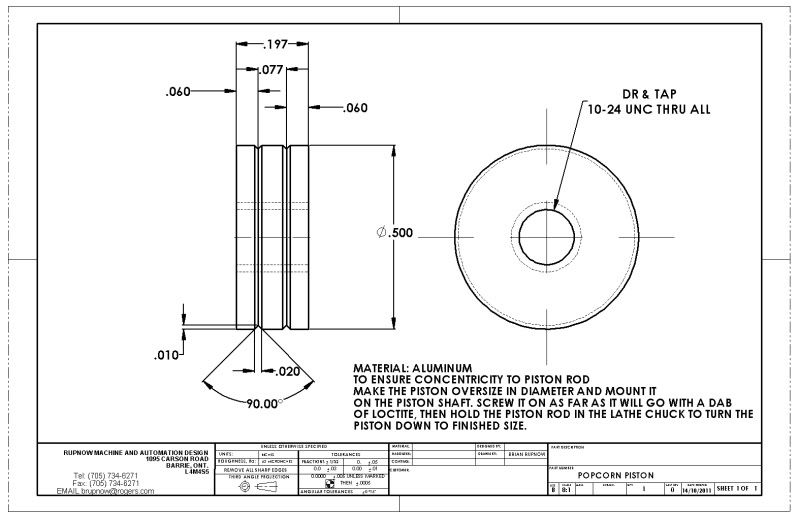

Brian Rupnow said:Kvom---a 3/4" endmill cuts a 3/8" radius.

Enter your email address to join: