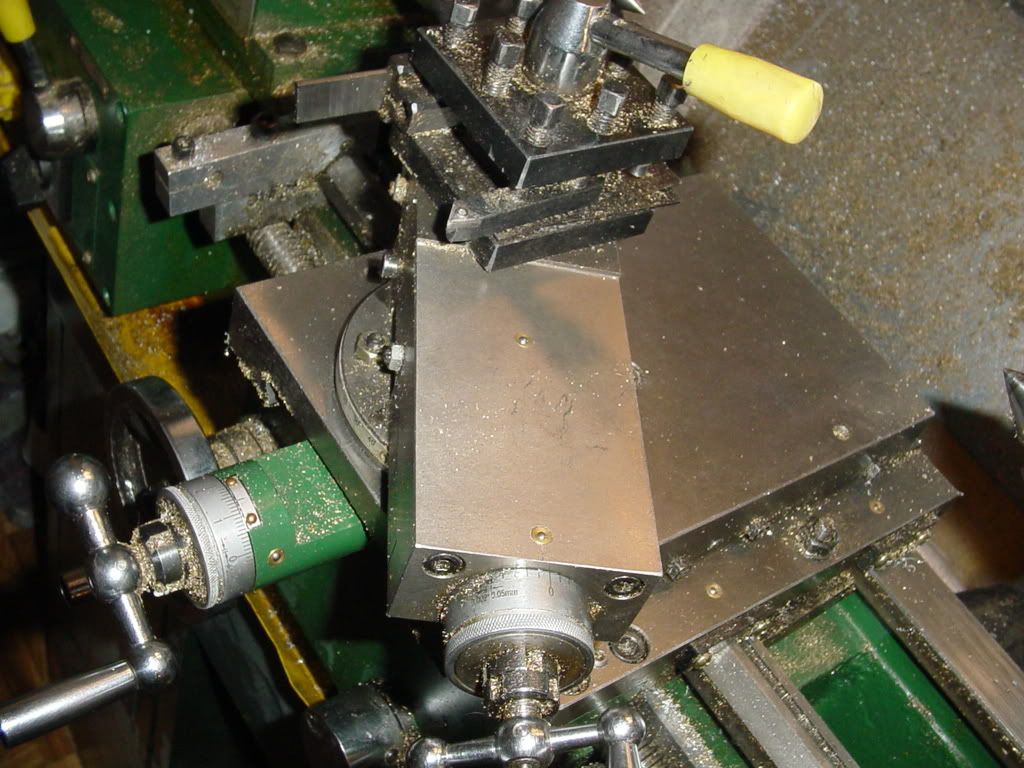

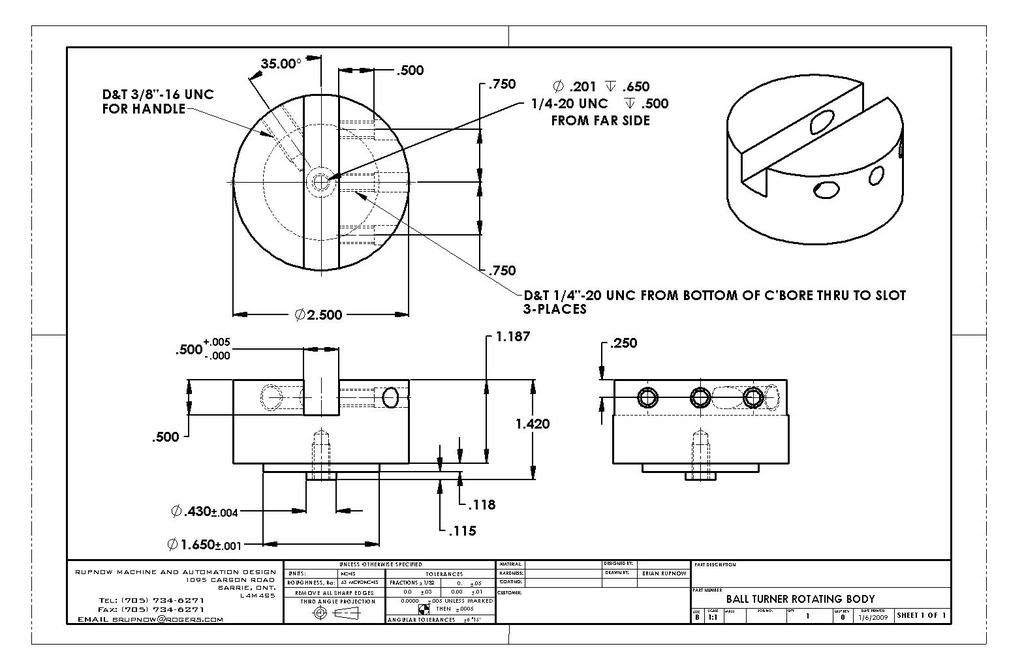

I take no credit for the designs shown in the following post. A gentleman named Steve Bedair seems to be the person who originally came up with this ball turner, and DividedHead did a couple of marvelous videos of it in operation. http://bedair.org/Ball/ball.html I have been curious about ball turners for some time, and up untill now they were a bit of a mystery to me. I am totally "Holidayed Out" today, so I spent the day studying ball turners. I took the information from a set of plans that were posted on Steve Bedairs website, and went about seeing what would have to be done to make and mount one on my specific lathe. ---And of course, since I have a bunch of carbide insert tooling with 3/8" square shanks, I designed the tool holder to suit my existing tools. Follow along if you like and perhaps you will gain a bit of insight into these marvelous tools

View attachment ASSY OF BALL TURNER.PDF

View attachment ASSY OF BALL TURNER.PDF