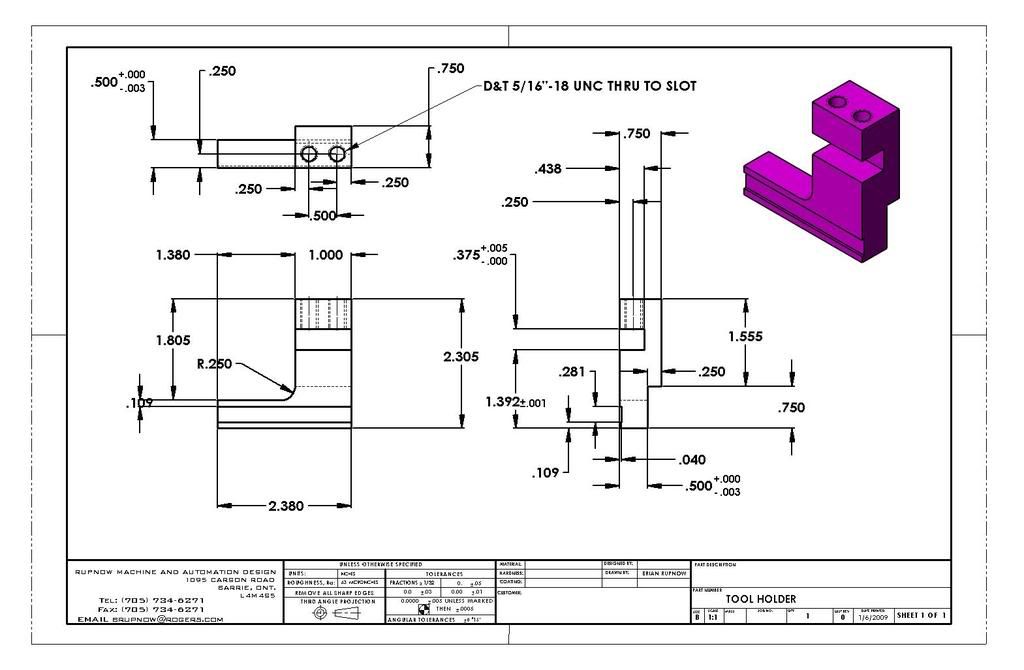

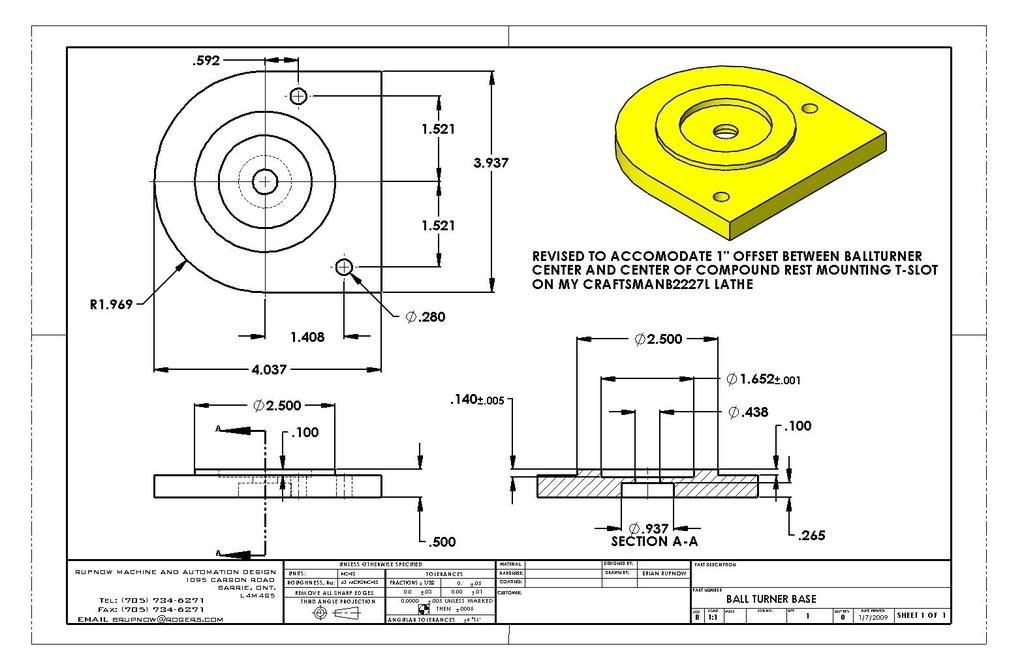

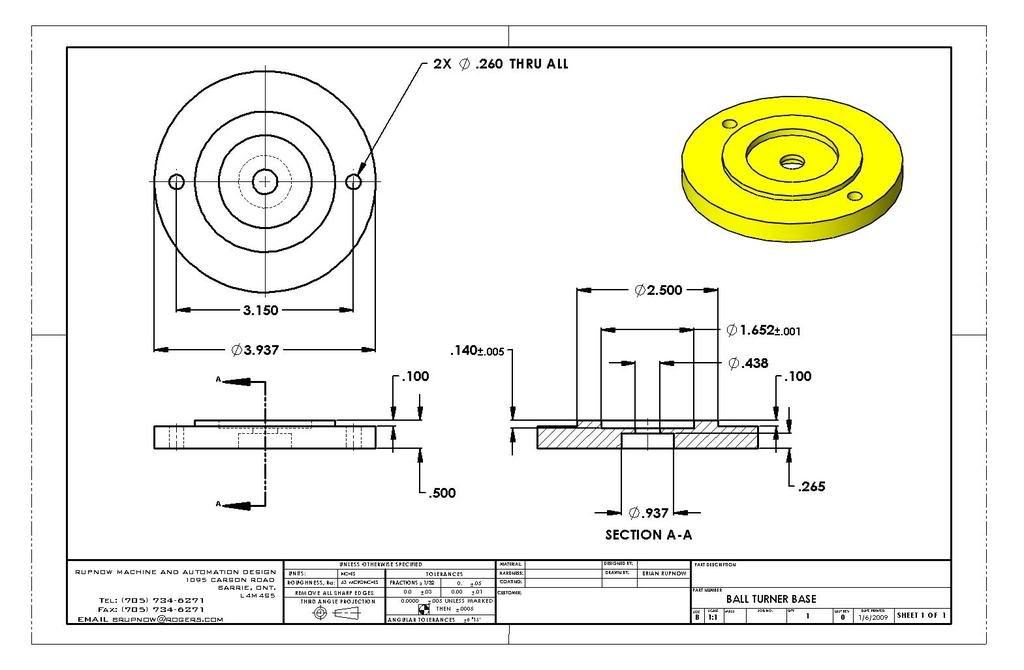

This is a drawing of the base, pretty well the same as Steve Bedairs. Keep in mind, however,as per the main general arrangement drawing at the beginning of this post, the hole centers and diameter and O.D. of the part are suited to my specific lathe. If your lathe is not a Craftex B2227L, then these dimensions will have to be changed to suit your own lathe.

View attachment BALL TURNER BASE.PDF

View attachment BALL TURNER BASE.PDF