- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Brian

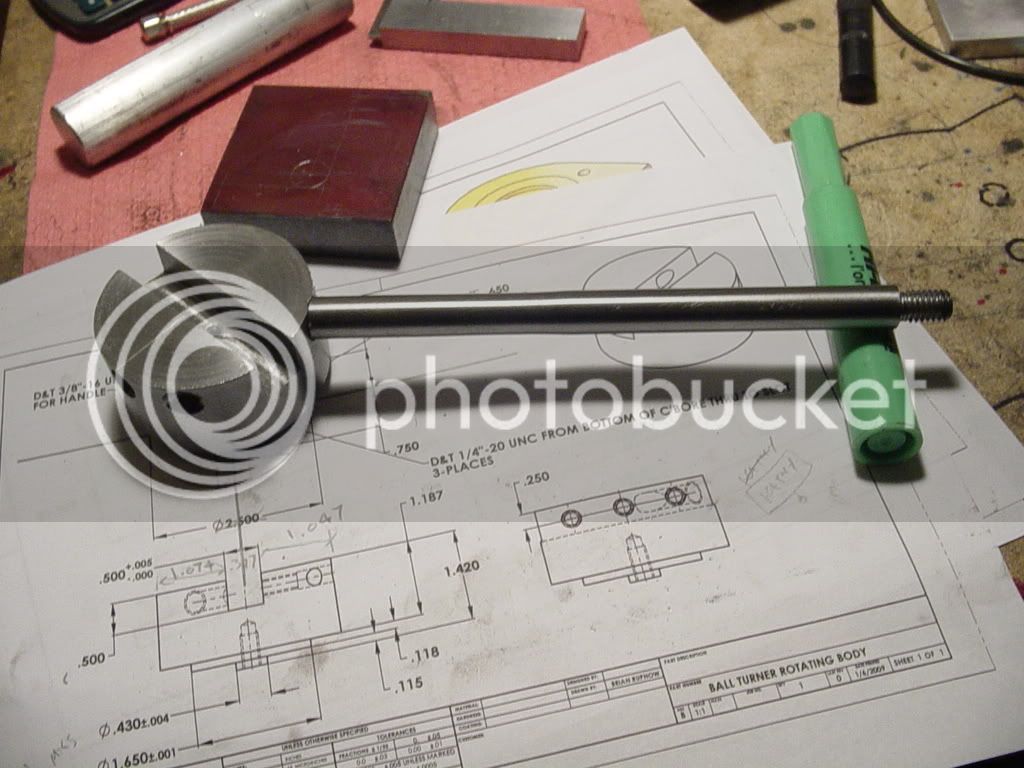

If the pivot point is short of the axis, you get a toroid, not an ogive. You may want to allow the pivot to go past the axis in case you do want an ogive. A brass ogive might be a little heavy for a rocket nose but it makes a nice knob for the top of the sugarbowl.

Jerry

If the pivot point is short of the axis, you get a toroid, not an ogive. You may want to allow the pivot to go past the axis in case you do want an ogive. A brass ogive might be a little heavy for a rocket nose but it makes a nice knob for the top of the sugarbowl.

Jerry