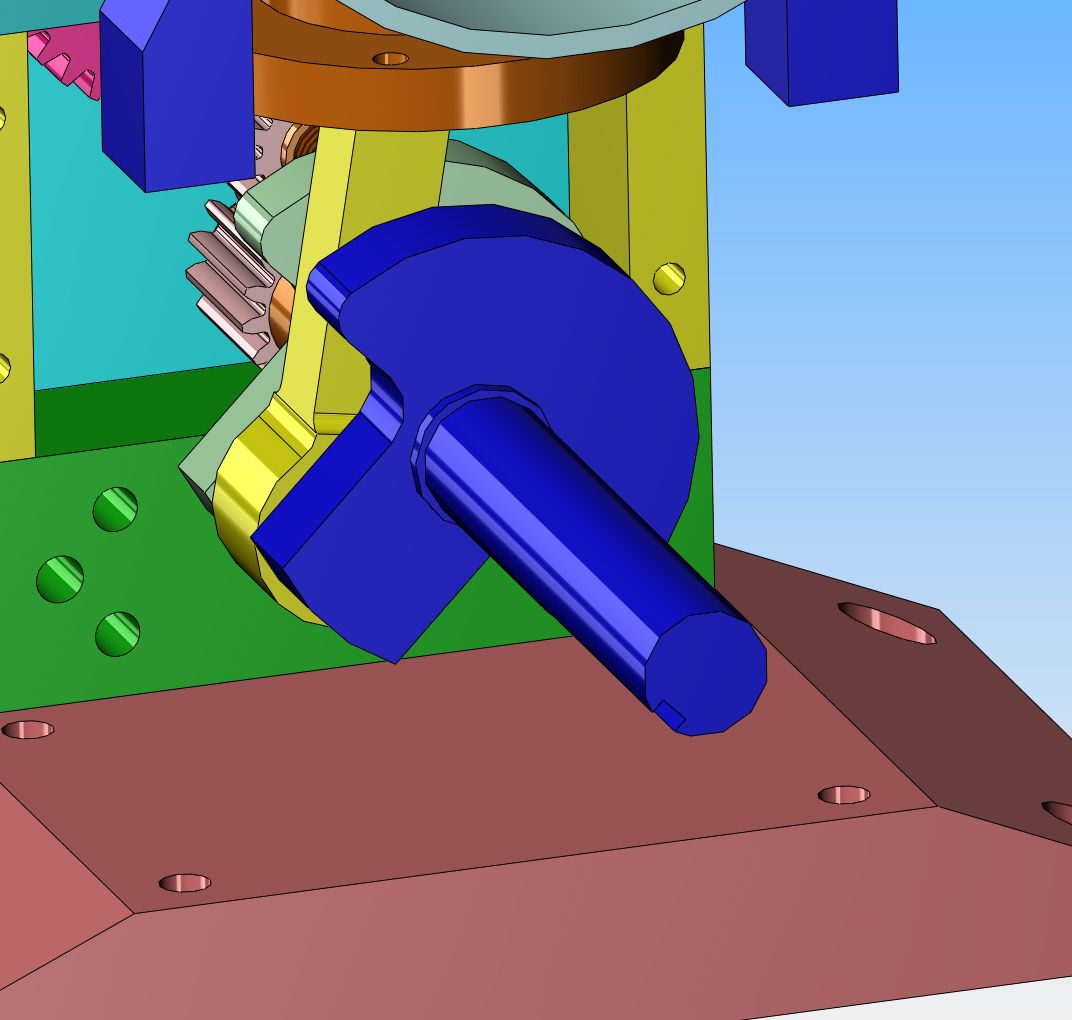

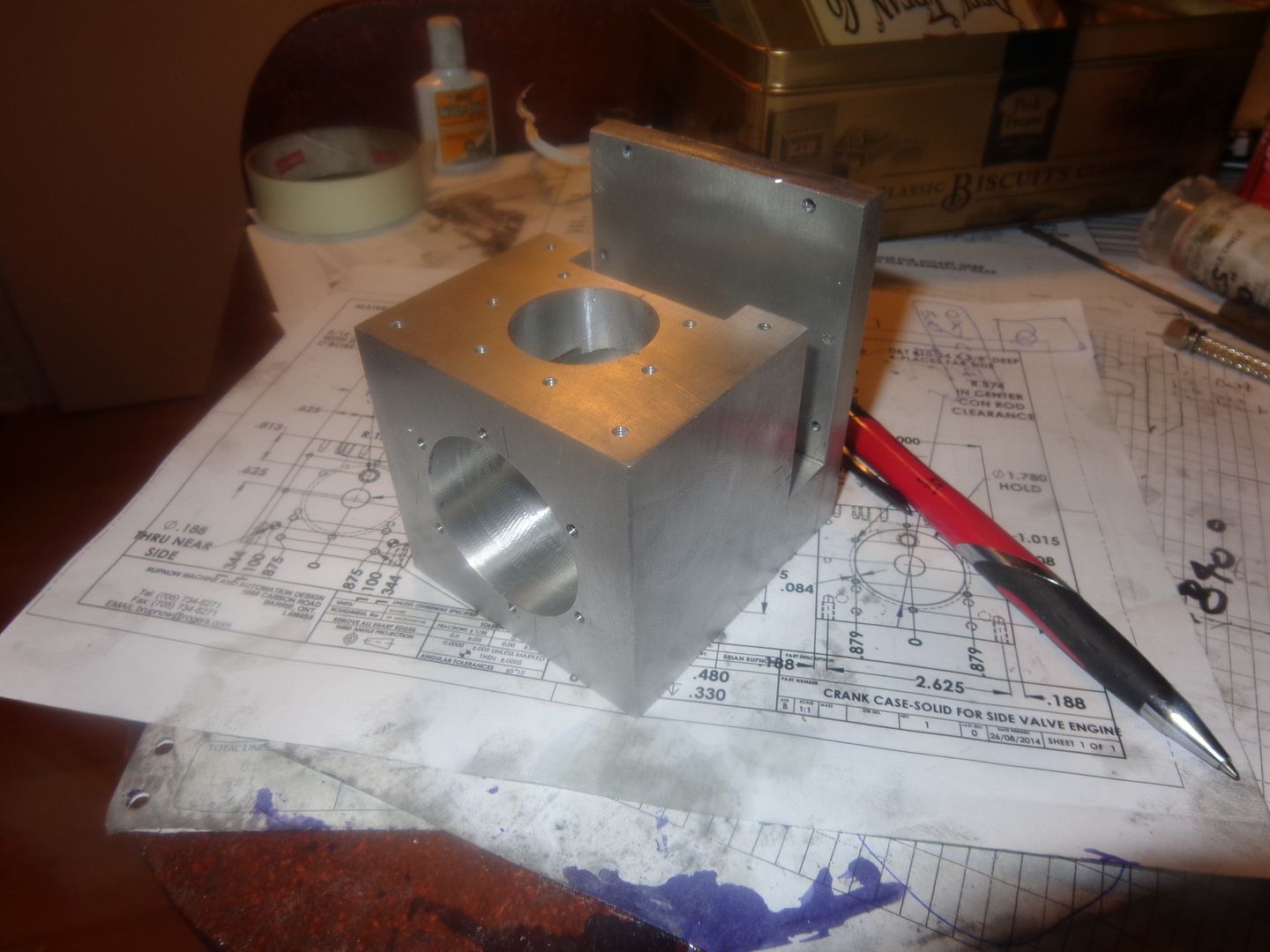

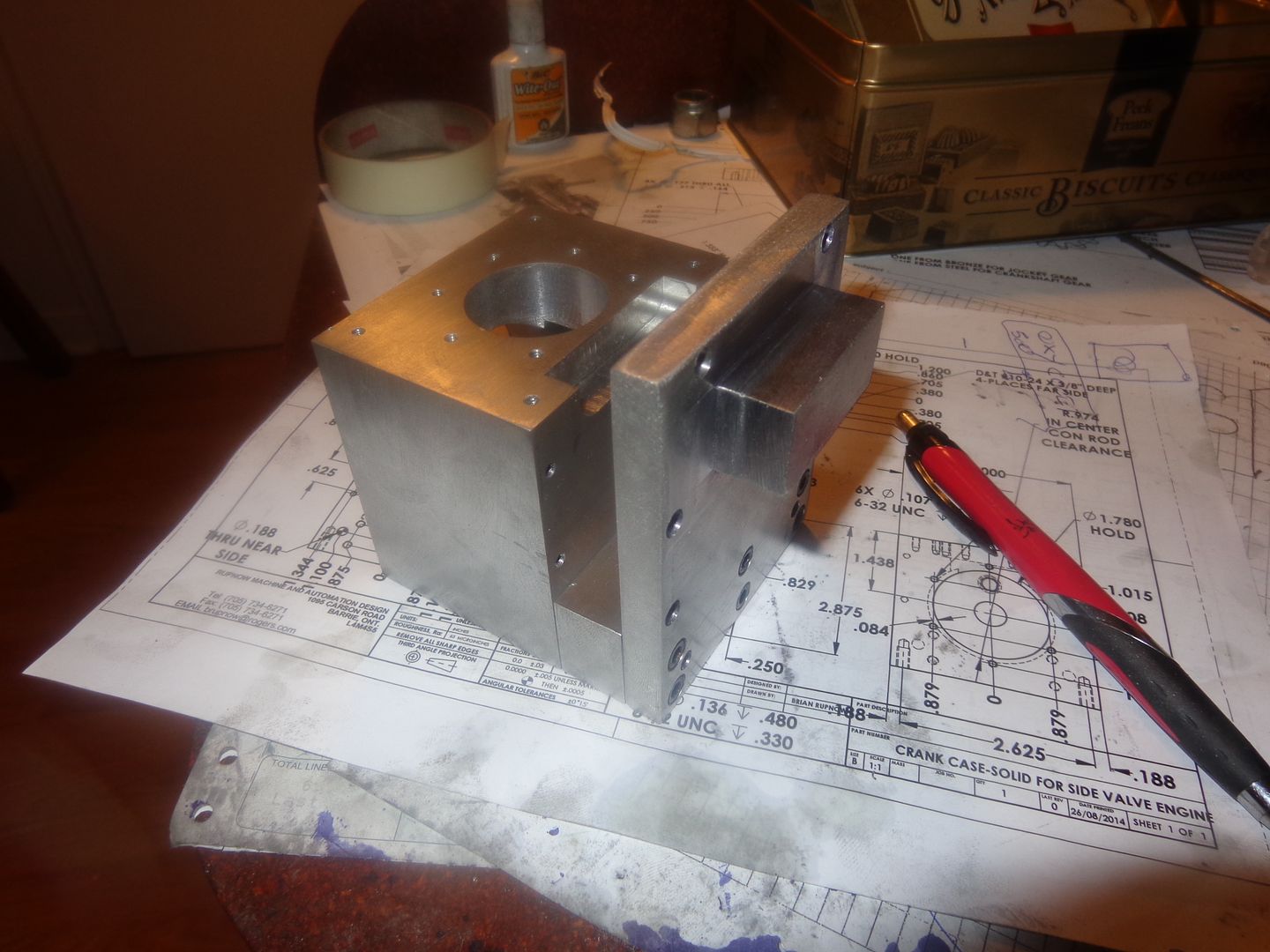

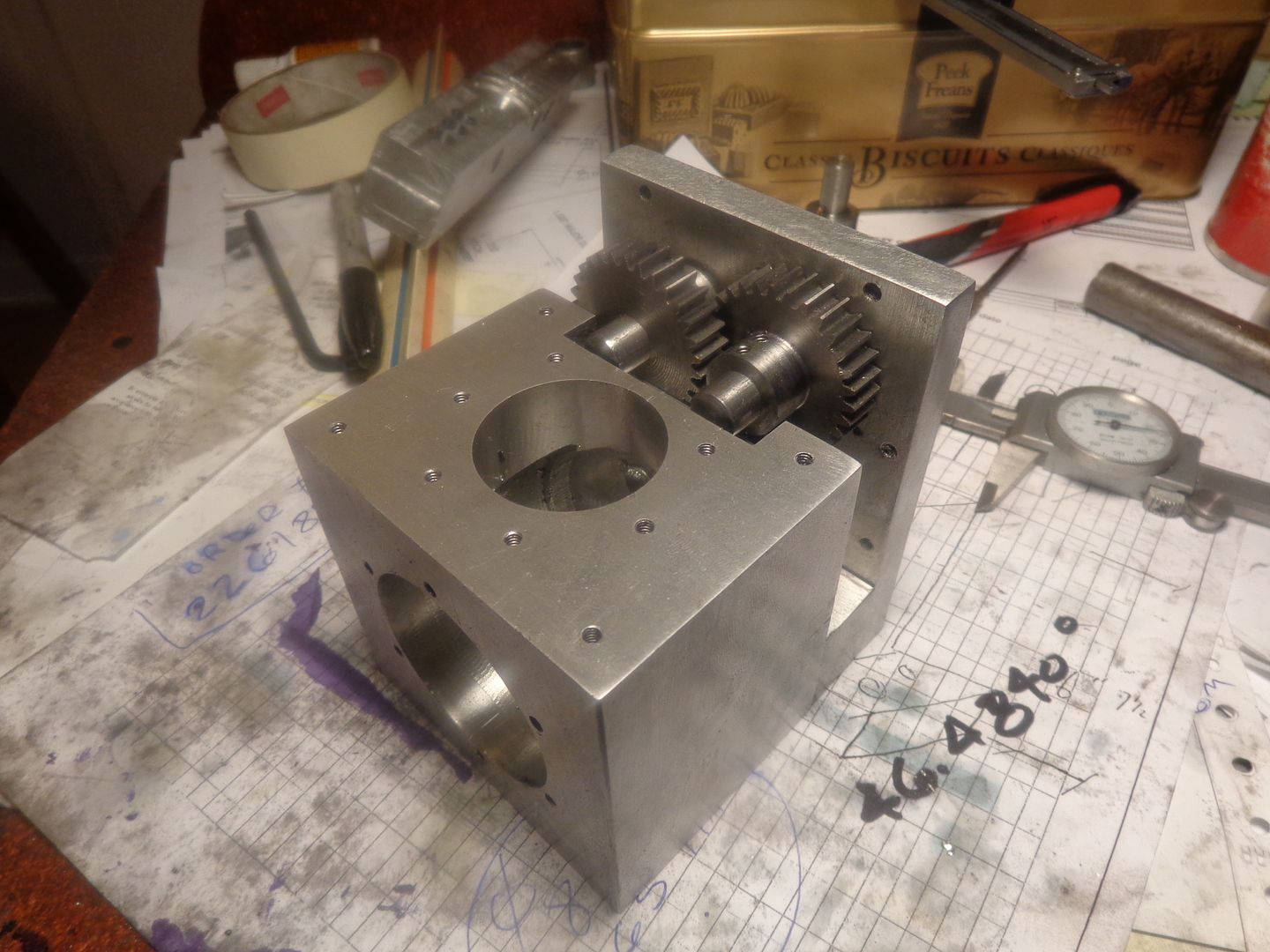

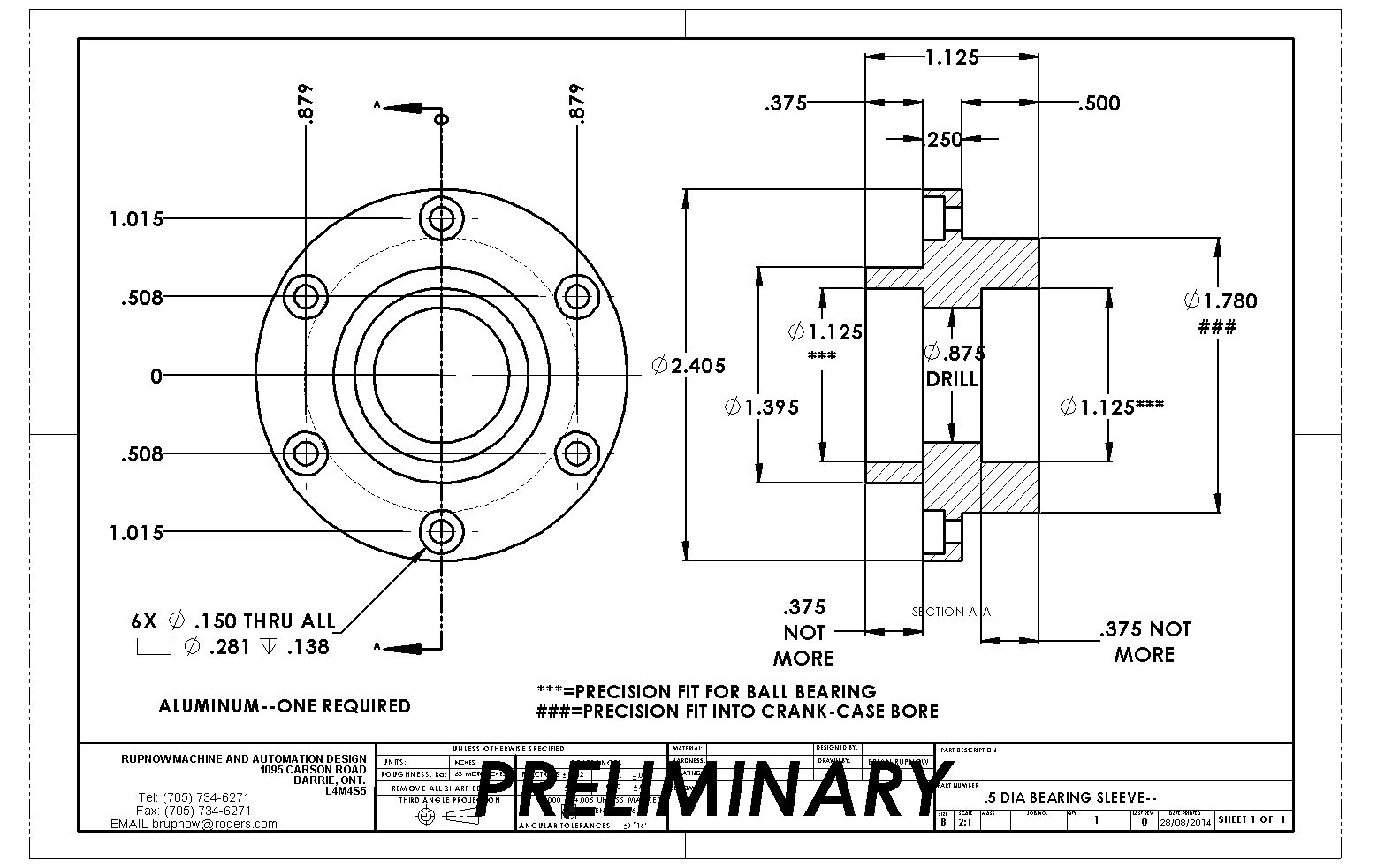

So---what do you do with sticky gears??---Well, if you live at my house you find a way to "unsticky" them. There are a host of different reasons that gear trains can be sticky---some can be fixed without setting the gears back up in the rotary table/mill and recutting them, and some can't. If the shaft centers for the shafts supporting the gears are not drilled the correct distance apart, well, you're toast. Nothing can fix that except maybe, if you are very very lucky you can SOMETIMES take a very small cut off the o.d. of the gears, to prevent the tip of the tooth on one gear from bottoming out on the root of the other gear, if the holes are drilled a few thou too close together. If the holes are too far apart, the gears will work, but will be noisy. If ya don't believe me, you can ask Chuck Fellows about that one. Sometimes gears are sticky even when the shaft centers are drilled "Right on". That can be put down to the tooth form being off a little bit, or a bit of spring in the arbor when the gears are being cut. Sometimes it seems to be just plain orneryness (if that's a word). About half the time, the gears I cut run together perfectly. The other half the time---well---If I can get the gears to turn at all (meaning they aren't locked up solid with each other). I cover the faces with a bit of 300 to 400 grit carborundum paste and put some power to them. Not for long, and not too fast, because that stuff cuts fast, and we don't want gears with pointy teeth!!! I recommend a rotating speed of about 300 rpm, and a time of about 15 minutes. If they aren't "unstickied" by then, run them in reverse for the same amount of time. The carborundum paste works very well, and once you can turn the gears freely by hand, take everything apart and wash everything really well with Varsol or a similar solvent. If you are still not 100% happy with the way they mesh, then cover everything with a good slather of grease, set them up with a power source, and let them run for an hour or two. The set-up in my attached picture shows the engine I am building with all 4 gears in place, covered with grease, and running in my milling machine. They turn very freely now, and should give trouble free service when I get the engine finished. The crankshaft gear is cut from cold rolled steel, the jockey gear is cut from cast iron, and the two large gears for the cams are cut from 1144 stress proof material. As I said in an earlier post, spur gears can be very noisy when running on a small engine with no gear cover. The gear cover serves two functions, one being to keep a good supply of grease around the gears, and another equally important reason is to keep the sound of the gears meshing contained.