- Joined

- Jun 24, 2010

- Messages

- 2,361

- Reaction score

- 932

Nice work Brian. Question on your SW drawings showing involute gear tooth form, do you have a trick to draw them for given size? Or downloaded accompanying 3D part from gear supplier or..?

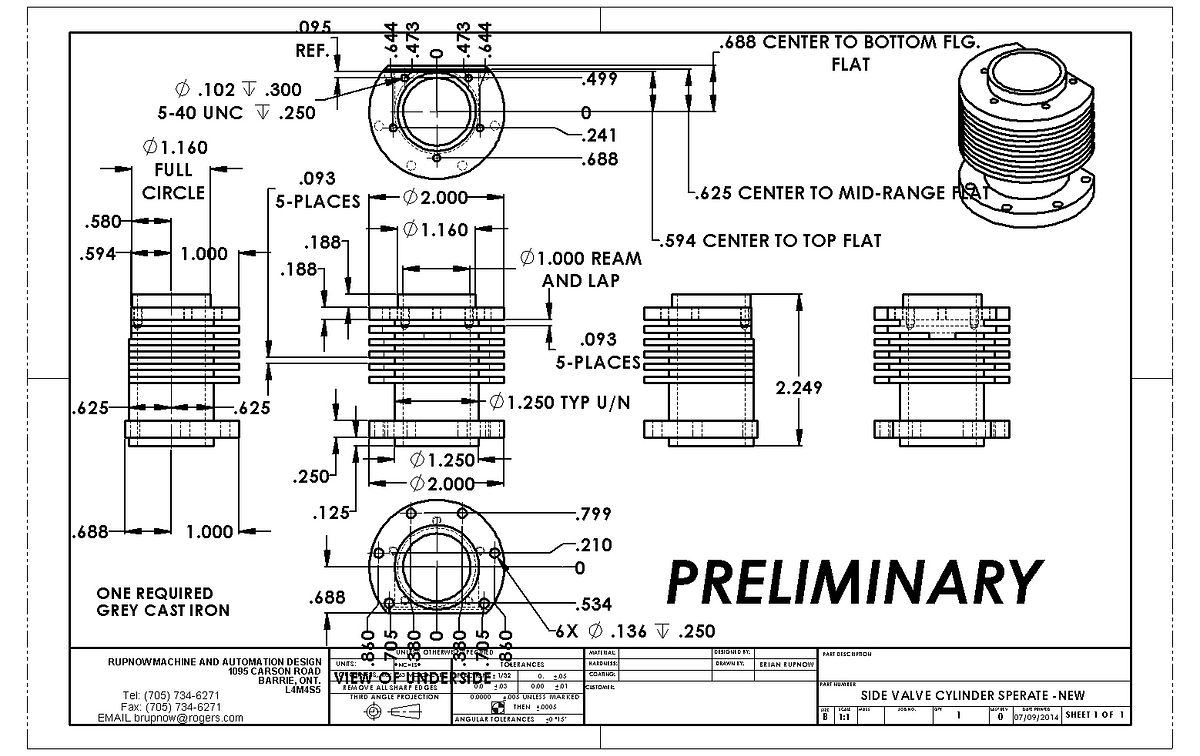

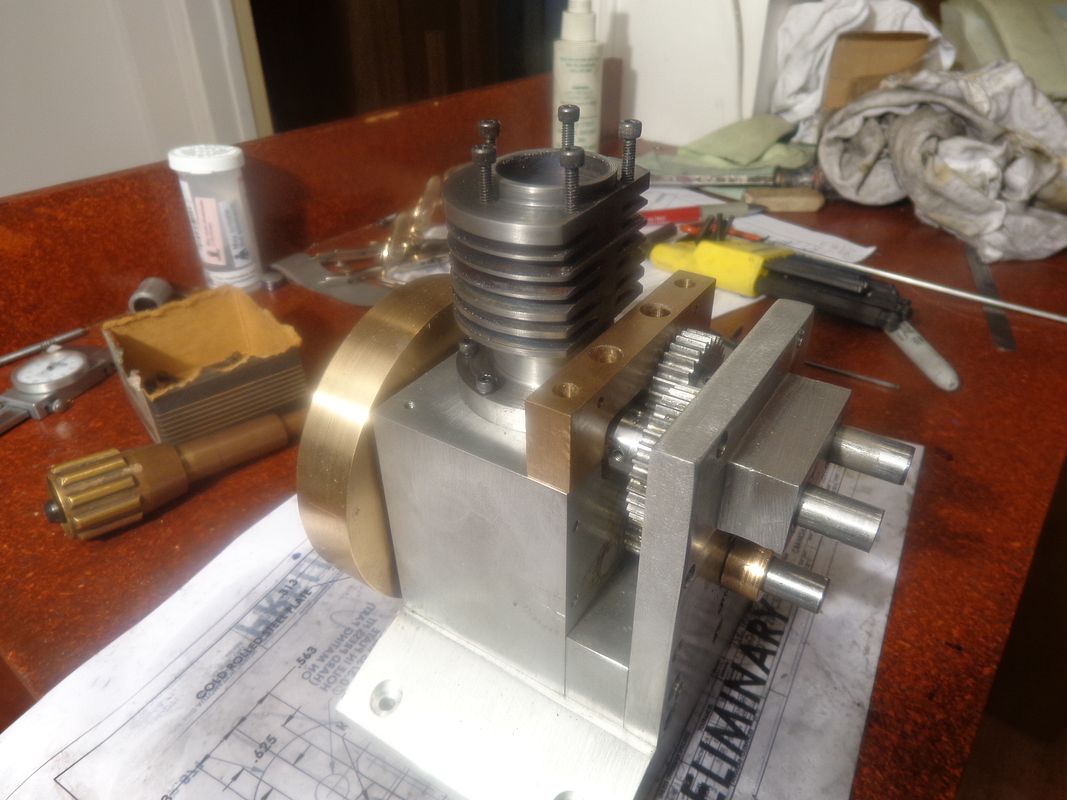

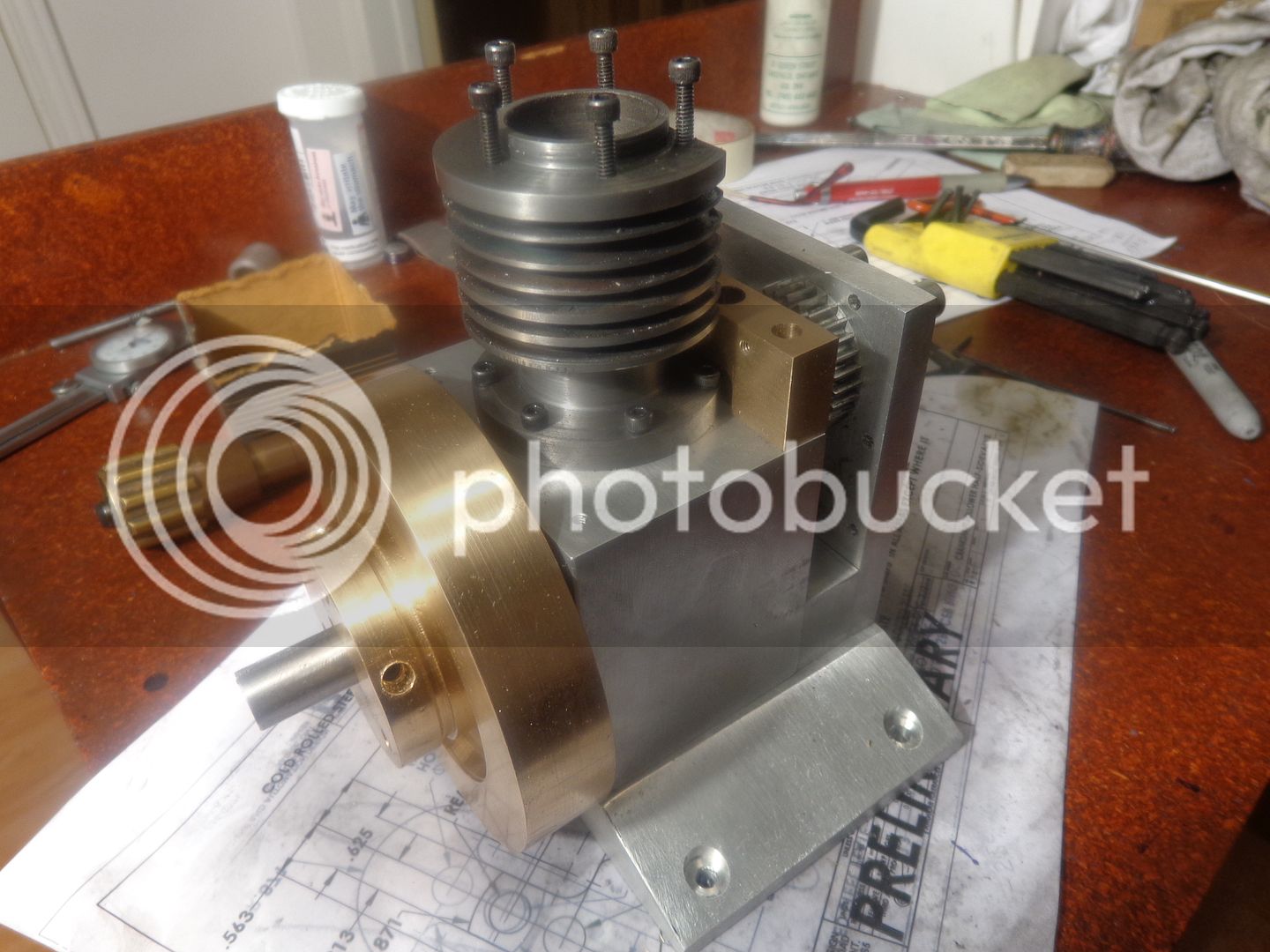

bmac2---Thanks for stopping by and saying Hi. When I get to this stage of a build, and people don't have much to say, I always start to wonder if I'm posting in a vacuum and nobody is looking. I'm just getting to the exciting part now. Next up will be the two piece cylinder.-- We had a really vicious rainstorm here for about 20 minutes, but no damage at my place. We had a few tornados touch down in nearby areas, but once you get out of the towns here, there isn't much but bush, so the only homes lost belonged to the bears and the deer.-Brian

Enter your email address to join: