About 6 months ago, I started feeling like it would be nice to have a small lathe to accompany my Myford ML7.

I love the old girl (the ML7), she's done everything I've thrown at her - to the extent of even mild abuse; us newbies can be hard on machine tools. I'd like the ML7 to last me a very long time indeed, but using a machine will wear it, and regularly making small or even tiny parts close to the chuck is the worst for this.

There was a small 5x9 (or 6x9 or 5x10 or 6x10 ?? - well, 140x250 in mm) Chinese lathe standing in a shop here in Windhoek, and I visited a couple of times over many months to assess whether I would spend my money on it, and what it would need done to it to make it worthwhile to buy. From what I could see, a complete strip-down, new gibs all round and a lot of additional fettling to clean up poor workmanship and get rid of burrs - hence a lot of work. Finance was a consideration as well, and after a small windfall, I decided to go for it as I was sure I could do the mechanical modifications needed. When I got to the shop, it was gone

- sold a week earlier. No problem; they could order me another one at the same price... So I said "go for it" and forked over the money; in Namibia it's pay-up-front when ordering, unless you have a business and account.

Patience is a virtue... Today it was nearly two months down the line since ordering, and I received a call... "Your lathe's here - you can come and collect it. It's not red though; it's yellow". Well, for me it's to heck with the colour anyway; I'd prefer grey or light blue any time, but colours does not make a machine or machinist worth anything...

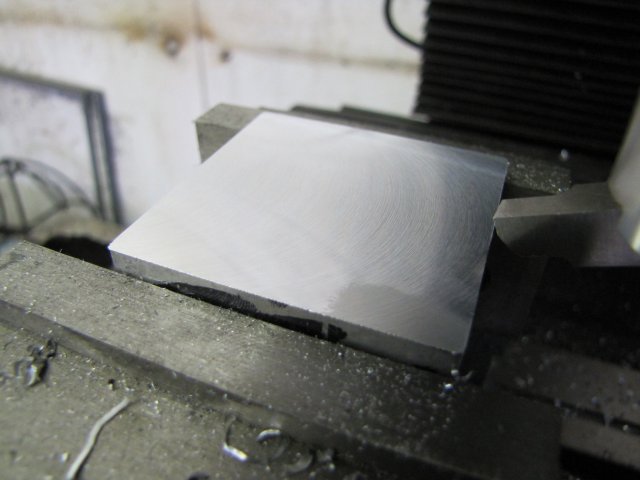

I brought this home:

And WHAT A PLEASANT SURPRISE!

According to the paper work, this one was built in March this year, and compared to the other older display lathe I wanted to buy, improved a hell of a lot. All the gibs are close fitting with none of the horrors I've seen in other posts, or indeed on the one I originally wanted to buy. In fact, this little machine somehow has a feeling of quality around it - I have not detected any burrs left on moving parts, and everything works smoothly, and that's even before I'm going to strip it down for a clean-up to remove the factory rust protectant and all of that and lubricate it properly. And it even has zero-able dials right through!

Compared to my Chinese drill press and Milling machine, this lathe shows a vast improvement in build quality.

Its not all moonshine & roses though :big: - it has a very limited set of gearing for thread cutting - metric only and not a big range either. I'll make gear sets as I need them - or use the ML7 for screw cutting. Standard accessories only extends to a 3-jaw chuck with inner & outer jaws and a fixed tailstock center. I need a revolving tailstock center, 4-jaw chuck (go ahead and laugh, but a 4-jaw is indispensable IMHO), and a collet chuck. And a tailstock drill chuck - a hobby lathe is pretty much useless without one :

- one of the reasons I bought this lathe is for drilling small holes in workpieces as the ML7 only gets up to about 800RPM and this 'un can do 3000 rpm according to specs.

Overall though, I think I'm going to have a lot of fun with this "little" addition to my shop ;D

Regards, Arnold

Oh and, that spring-loaded "safety" chuck key that came with it is going to get a lesson in aerodynamics...