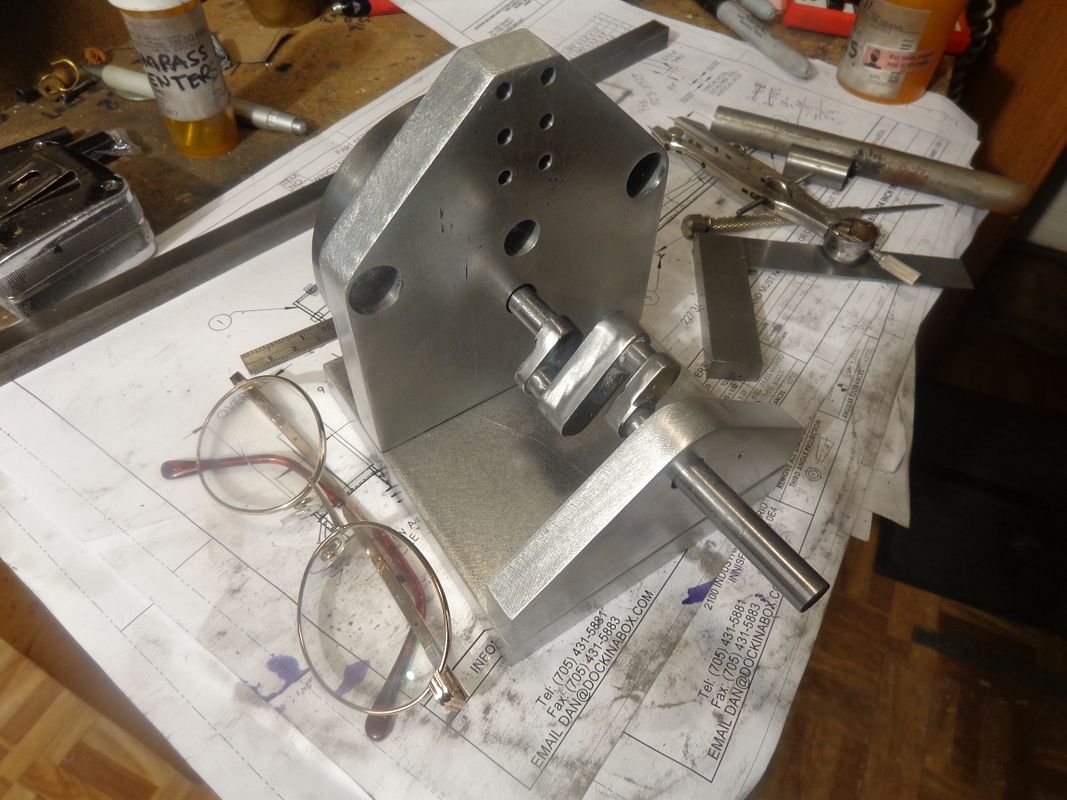

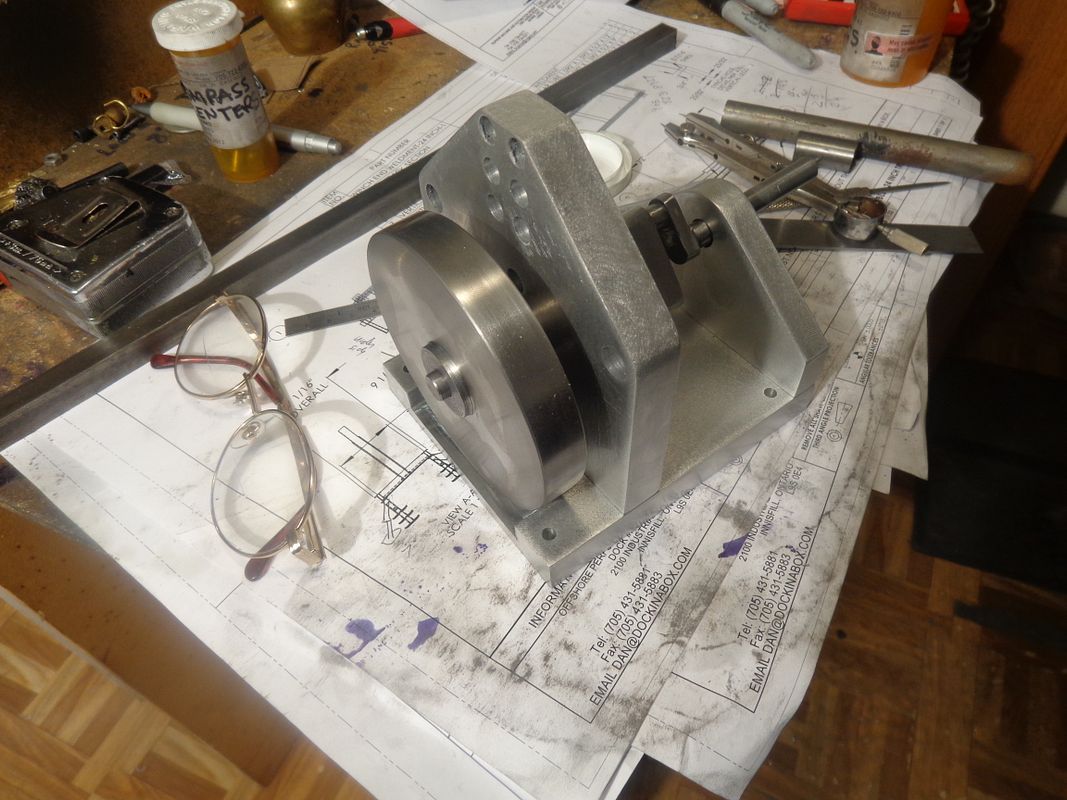

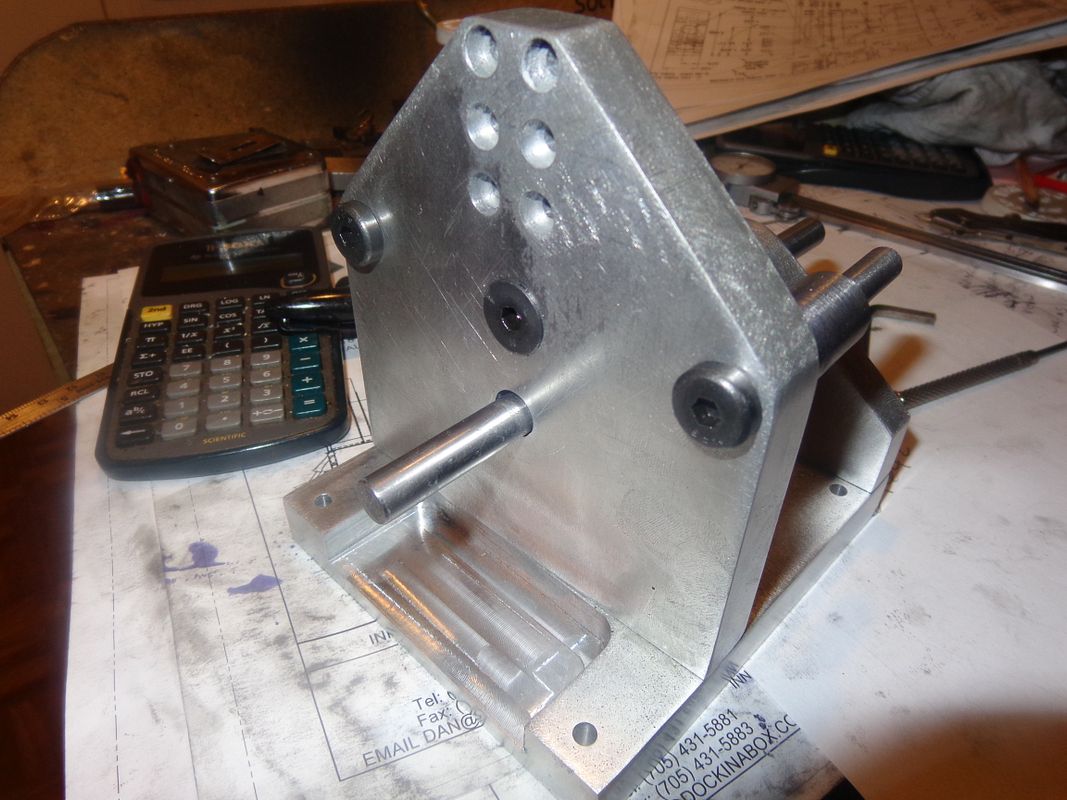

This is what $50 buys this morning!! A piece of 5/8" aluminum 5" x 5/8" x 16", a piece of cast iron 4" diameter x 1 3/8" long, and a piece of 1/2" square cold rolled x 19" long. The plate will give enough material to build the complete plate frame (I will have to mill part of it down to 1/2" thick for the front bearing support plate.)--Also, the cast iron will build my flywheel. The plate was $30 The cast iron was $20 (would have been $15 if I had chosen hotrolled 4" dia. steel instead.) The 1/2" square cold rolled was thrown in as a free-bee. I got it because, if that welded crankshaft I made is hinky, I will make up a second one with 1/2" square webs instead of 3/16" thick, and Loctite/dowel it together instead of welding it.