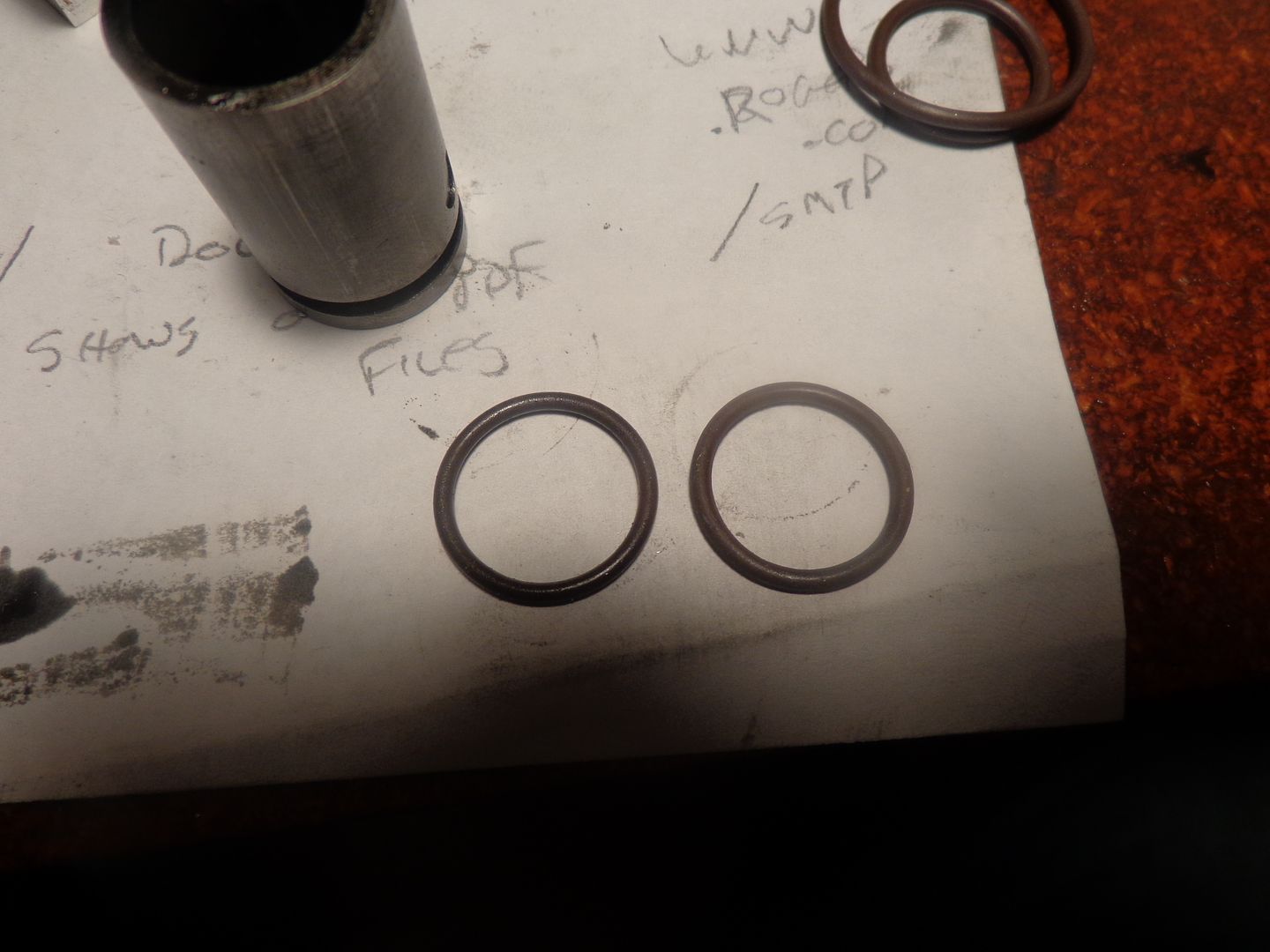

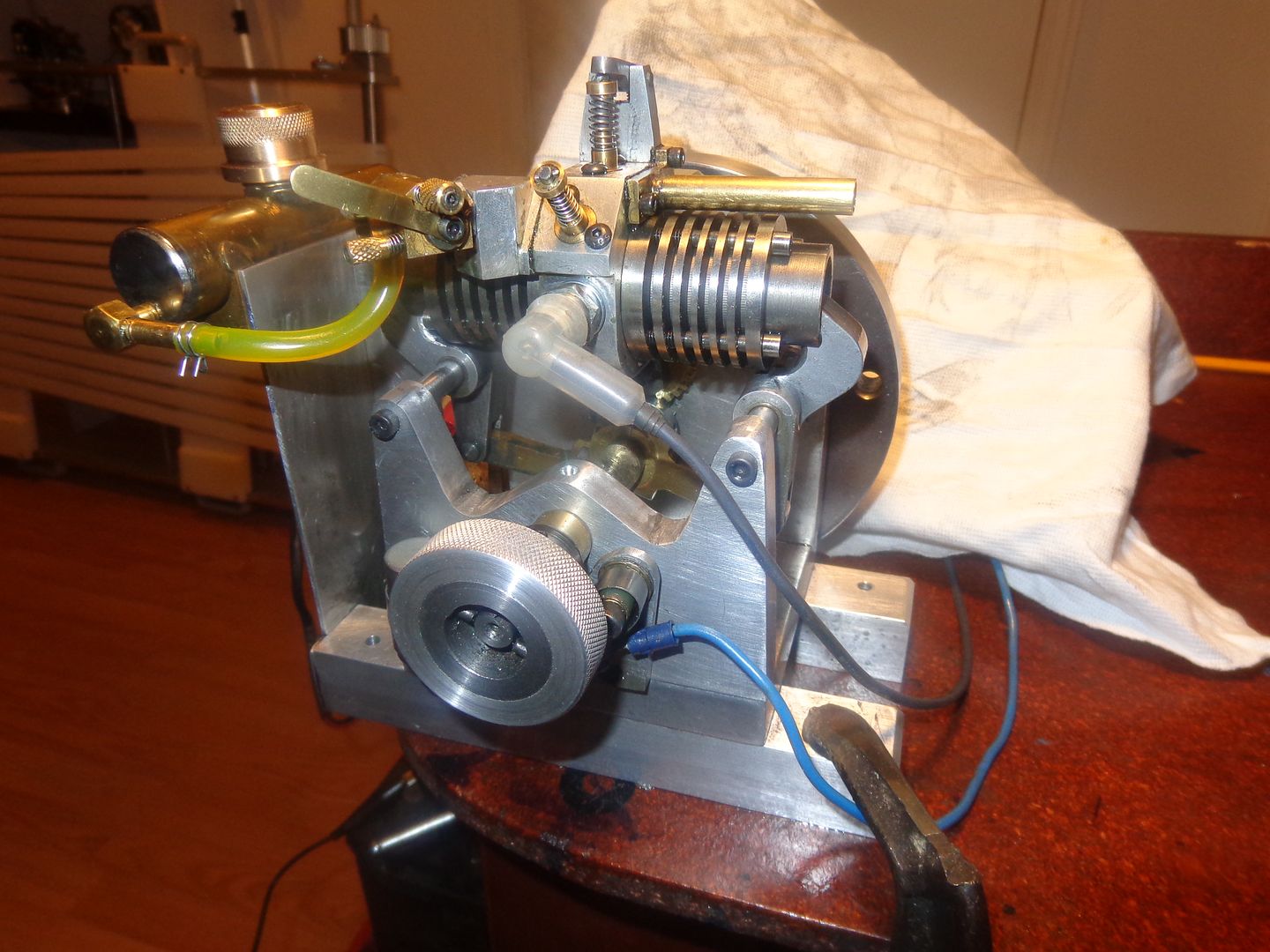

This morning I decided to pull the pistons out of the engine and check the condition of the rings. You may remember that on an earlier post I said I could hear air escaping from the open end of the cylinders when turning the engine by hand on the compression stroke. I surmised that perhaps the inside of my cast iron cylinders might not have been a "mirror finish" and consequently worn some material off the outer diameter of the Viton O-rings during the "break in" phase of running the engine. I pulled the old rings out, and although I couldn't see any specific damaged areas, the whole ring looked slightly smaller than one of the new "spares". It is not much difference. The ring on the right side of the picture is brand new, the ring on the left is one of the worn ones I removed form the engine. HOWEVER--When I reassembled the engine, it is much stiffer to turn over by hand, and there doesn't appear to be any air escaping past the open end of the cylinder on the compression stroke. Since I didn't remove the crankshaft nor bearing supports, this new "stiffness" can only be attributed to the fit of the rings into the cylinder.