You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

90 degree V-twin engine

- Thread starter gbritnell

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jul 16, 2007

- Messages

- 2,993

- Reaction score

- 1,061

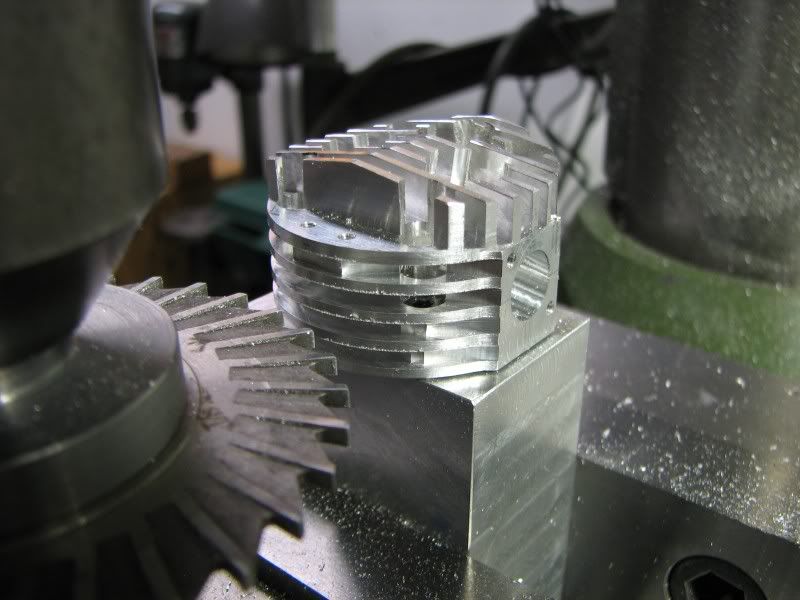

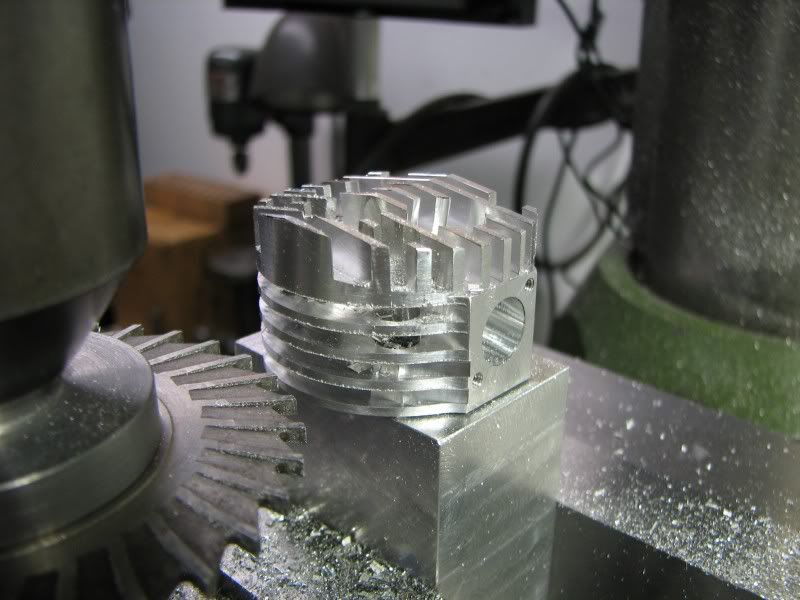

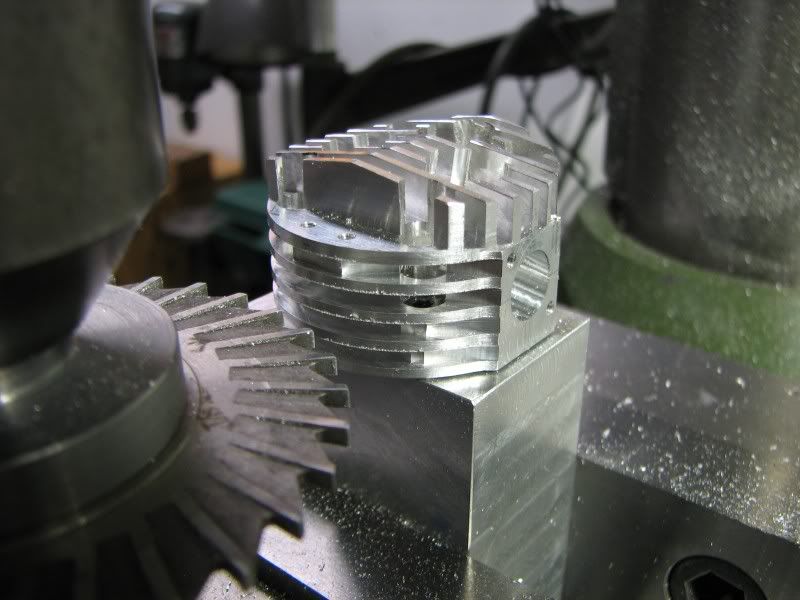

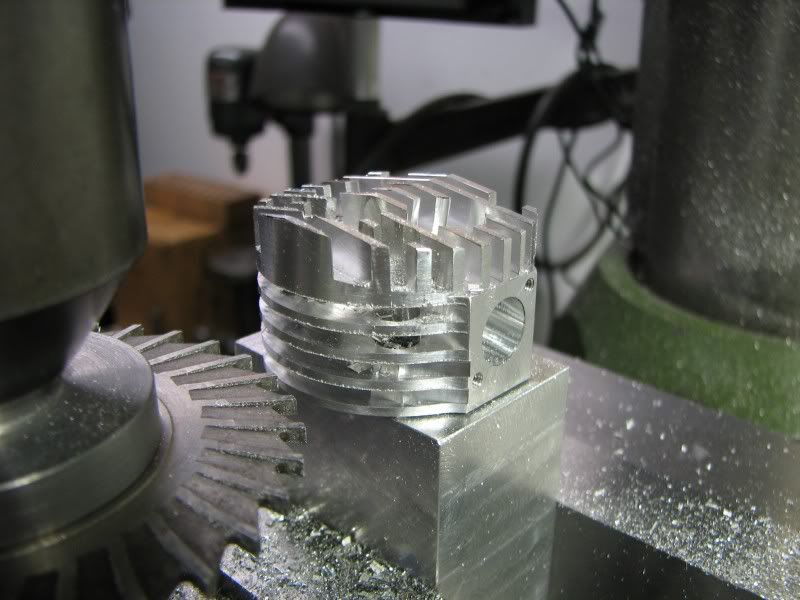

Today's work was to put the horizontal fins into the heads. The first thing was to clean up the mess from yesterday's fin cutting. The mill saw makes very small chips and they were everywhere. I had to take the vise off to make sure it was clean underneath from rotating it back and forth. Once that was finished and the vise was remounted and indicated I clamped my fixture bar into it. As with the top fins I set my indicator to the rocker arm surface and made sure the top of the cutter was at -0-. The horizontal fins are more complicated because I have several depths to go to on each side and then there are scallops that remove the extra metal and are tangent to the manifold faces. My original drawings and layouts were to use a 1.50 inch saw but they never came in from the supplier so I changed my layout and went with the 3.00 inch saw. The difference in the remaining metal is minimal. The first two pictures are both sides of the head with the fins cut on the fixture bar. The last two pictures are the finished heads. Tomorrow I'll clean up all the burrs, radius the corners and polish everything up. Just the valve guides left to machine and these parts will be done.

George

George

- Joined

- Jul 16, 2007

- Messages

- 2,993

- Reaction score

- 1,061

Thanks CMS, as a matter of fact I can, draw that is. It's a little of topic but here's a sampler. These are all colored pencil. I started working with colored pencils about 7 years ago, till then I mainly worked in watercolors.

gbritnell

gbritnell

crankshafter

Well-Known Member

- Joined

- Jul 17, 2007

- Messages

- 367

- Reaction score

- 24

George

You don't stop impressing/ amazing me. Thank you for showing your great project. :bow: :bow: You are a real wizzard. I wonder, is there anything you do't manage :big:

Crankshafter.

You don't stop impressing/ amazing me. Thank you for showing your great project. :bow: :bow: You are a real wizzard. I wonder, is there anything you do't manage :big:

Crankshafter.

Deanofid said:It seems we have a renaissance man in our midst.

hehe....SEEMS!?......George you are one amazing individual! :bow:

Dave

George, pardon the interruption, but a while back Dean had asked about the riffler files you were using on this project:

I was thinking about this while I had a few minutes in the shop this evening, and I took a couple of pics of some of the ones I have. Pretty standard stuff, I imagine similar to what you are using.

An overall view, and a few closeups of the styles I have. The "shepherds hook" and the loop style come in very handy for working in areas like the screw bosses on George's engine. With a little practice, you can get into some very tight spaces with these. I have some #0, #2, and #4 cut in the various shapes with #0 being the coarsest and #4 the finest cut.

George may have replied to the question already, and if so, I apologize for the distraction.

Thanks,

Kevin

Would you do us a favor next time you get into the shop, please? Take a photo of the rifflers you use for this work so we can see what you're working with. (I'm kind of interested in files and filing..)

I was thinking about this while I had a few minutes in the shop this evening, and I took a couple of pics of some of the ones I have. Pretty standard stuff, I imagine similar to what you are using.

An overall view, and a few closeups of the styles I have. The "shepherds hook" and the loop style come in very handy for working in areas like the screw bosses on George's engine. With a little practice, you can get into some very tight spaces with these. I have some #0, #2, and #4 cut in the various shapes with #0 being the coarsest and #4 the finest cut.

George may have replied to the question already, and if so, I apologize for the distraction.

Thanks,

Kevin

- Joined

- Jul 16, 2007

- Messages

- 2,993

- Reaction score

- 1,061

Kevin, I didn't reply and those are exactly what I use. I don't have quite as many as you. I have the shepherds crook, some bent flats and a few others. I buy them on occasion as they are real pricey.

George

George

dsquire

Well-Known Member

- Joined

- Mar 18, 2008

- Messages

- 980

- Reaction score

- 15

George

There are a lot of words used to describe what you have done both on a mechanical and artistic level and they all seem to be lacking. I don't have any better words to use so I'll just sit here and drool. th_wav

Cheers

Don

There are a lot of words used to describe what you have done both on a mechanical and artistic level and they all seem to be lacking. I don't have any better words to use so I'll just sit here and drool. th_wav

Cheers

Don

- Joined

- Jul 16, 2007

- Messages

- 2,993

- Reaction score

- 1,061

Well this wraps up the cylinder heads. I radiused all of the fins last night and I finished the valve guides this morning, pressed them in and rereamed them. They tightened up a little from pressing them in. I then mounted the rocker assemblies on to them just to see what they would look like, kind of like jumping ahead to see what it will look like when it's finished. I even held the head in the approximate position over the crankcase to get this imaginary vision. I'm happy with the way it's coming out.

George

George

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

Awesome... this thread is so much fun to watch... :bow:

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

Beautiful work George!

When I look at pictures of your finished parts, I catch myself

looking for tool marks. Every machining operation leaves tool marks.

With your attention to detail they are often very hard to find.

I look forward to every new picture!

Rick

When I look at pictures of your finished parts, I catch myself

looking for tool marks. Every machining operation leaves tool marks.

With your attention to detail they are often very hard to find.

I look forward to every new picture!

Rick

First, George, they look fantastic! If I have to use the same old words over and over, I guess I will, because I can't pass these photos without making some kind of remark. Looking back over the other parts, and putting them along side the cylinder heads in my imagination, I'm getting pretty excited to see the first assy pics.

Secondly, Kevin, thanks for the shots of the rifflers. Many of us like to see what tools others use for certain procedures. It's part of the learning process.

Dean

Secondly, Kevin, thanks for the shots of the rifflers. Many of us like to see what tools others use for certain procedures. It's part of the learning process.

Dean

rake60 said:When I look at pictures of your finished parts, I catch myself

looking for tool marks. Every machining operation leaves tool marks.

With your attention to detail they are often very hard to find.

Rick

in fact, that is one of the most important merits in the works of gbritnell (among many others!)

I try often to achieve the same results in the finish of parts, but inevitably some scratch here or there appears... :-\

and when they are done, they are difficult to remove

it is better to prevent them, but not so easy

Similar threads

- Replies

- 61

- Views

- 8K