canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

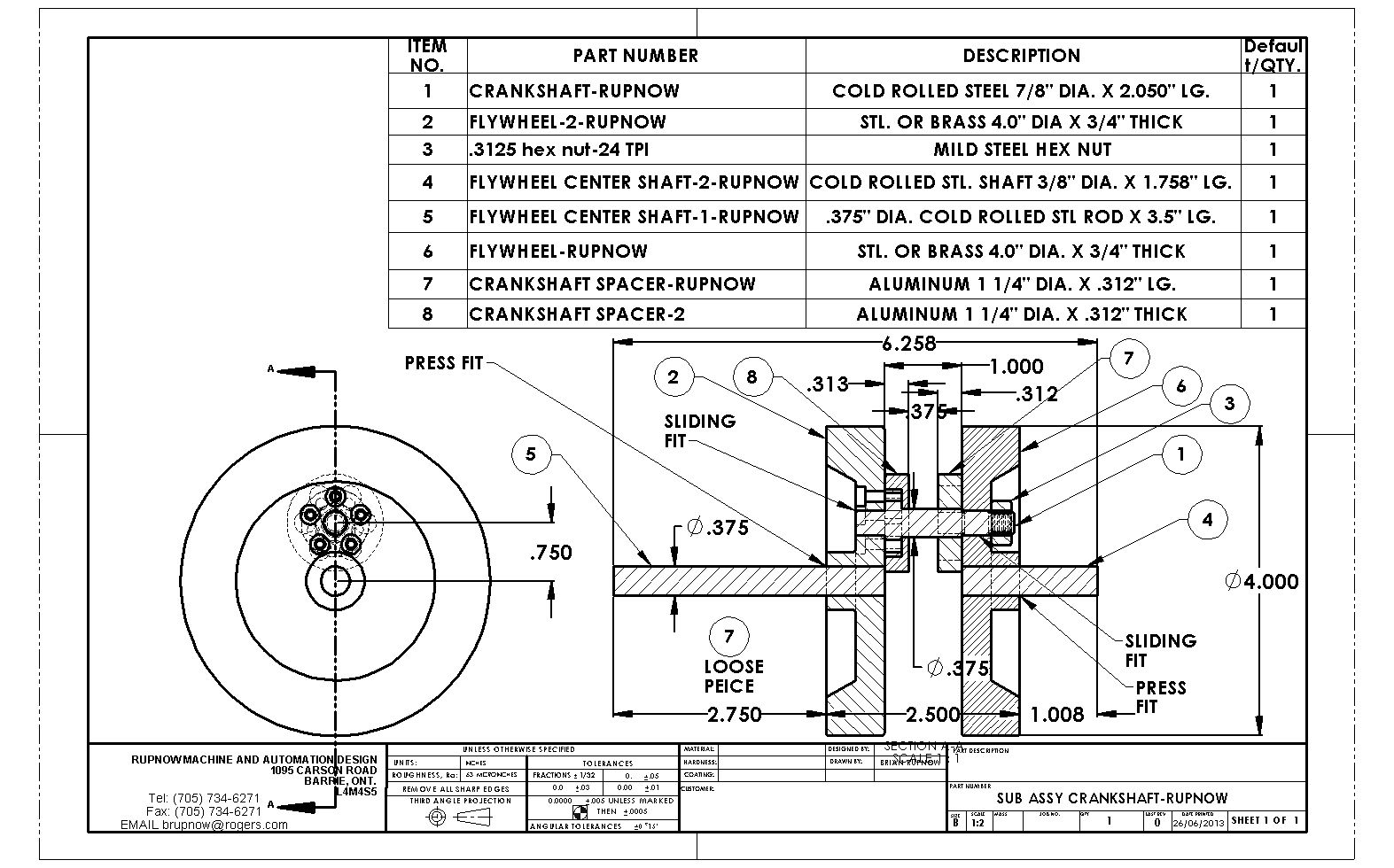

Look good, Thm ne more question is the rod going to be a 2 pcs or single

ne more question is the rod going to be a 2 pcs or single

and what is the rod bearing number??

and what is the rod bearing number??

Ausdier--Too bad, I wish you could have joined us. I guess Australia's honour is going to be upheld by Cogsy!!!

cogsy---I'm looking foreword to seeing your first post. That will make 2 Canadians, one Englishman and one Aussie building this engine.--This makes all the other nationalities out there either A----Wimps for holding back and not joining us., or B---People wiser than us who are going to set back in the bush and wait to see if this engine is successful!!!

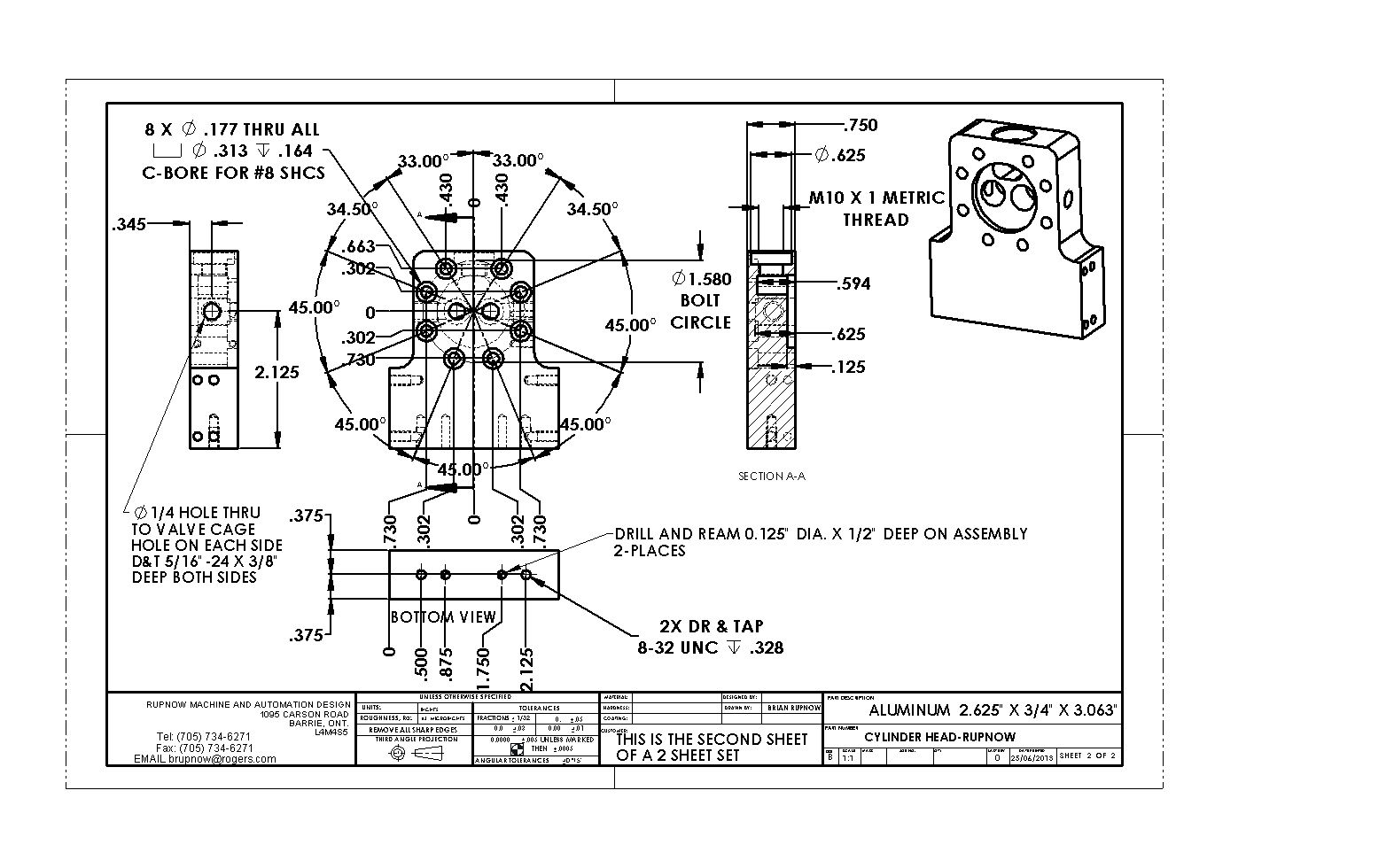

Yes Luke, you are probably right. I was trying to keep the flange the same diameter as the o.d. of the con rod. I will do a redesign on that part.---Brian

Enter your email address to join: