The rotational acceleration (centrifugal acceleration) is ( R omega squared.)

Omega ( W) should be in radians /second.

2 Pi N = 2 x 3.14159 X 100/60 = 10.47 rad/second for 100 rpm

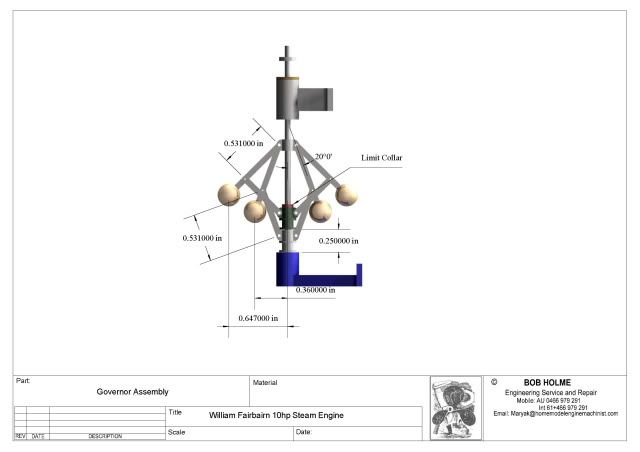

R you have stated as 0.0578 m

Therefore

.0578 x (10.47) squared = 6.33 meters / second squared

1 g is 9.81 meters / second squared......so

6.33/9.81 = 0.645 g's from centrifugal force...don't forget that gravity is pulling down with 1 g...

Ya need more speed....or bigger balls Bob ;D (Sorry it was too easy)

Because of the speed factor, I would speed the governer up

Dave

Omega ( W) should be in radians /second.

2 Pi N = 2 x 3.14159 X 100/60 = 10.47 rad/second for 100 rpm

R you have stated as 0.0578 m

Therefore

.0578 x (10.47) squared = 6.33 meters / second squared

1 g is 9.81 meters / second squared......so

6.33/9.81 = 0.645 g's from centrifugal force...don't forget that gravity is pulling down with 1 g...

Ya need more speed....or bigger balls Bob ;D (Sorry it was too easy)

Because of the speed factor, I would speed the governer up

Dave