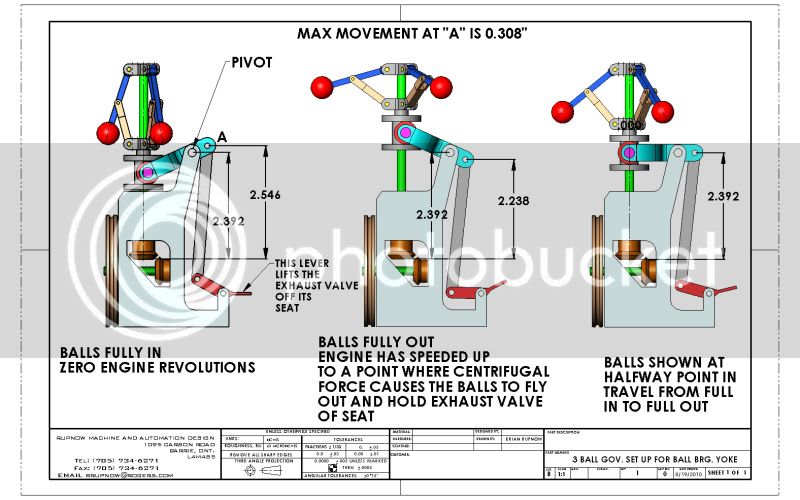

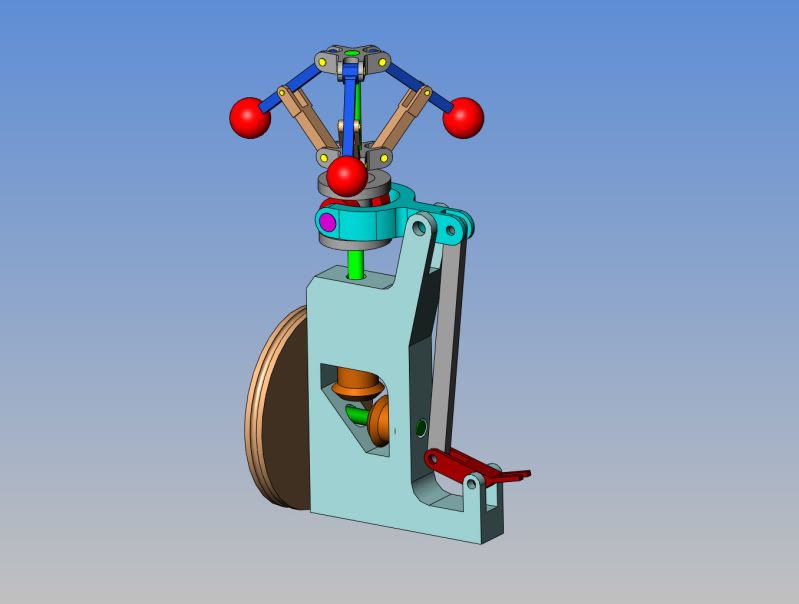

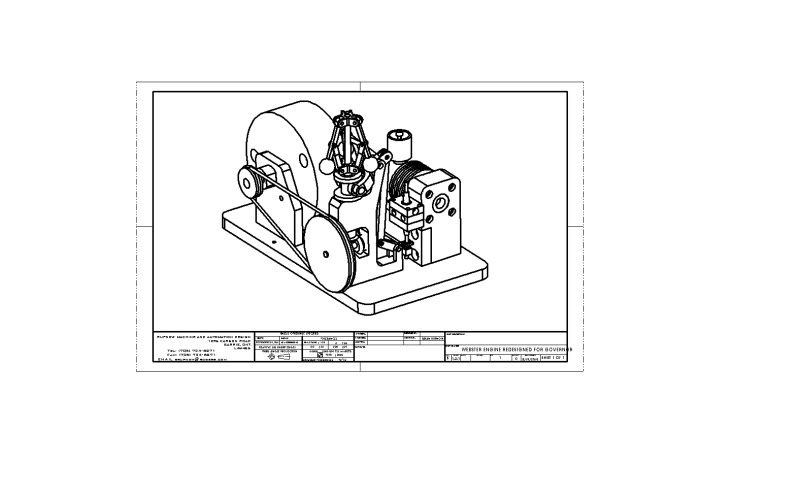

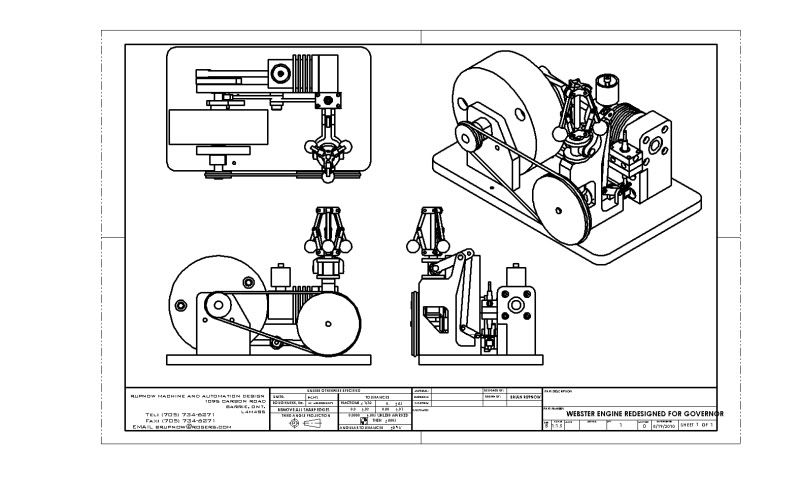

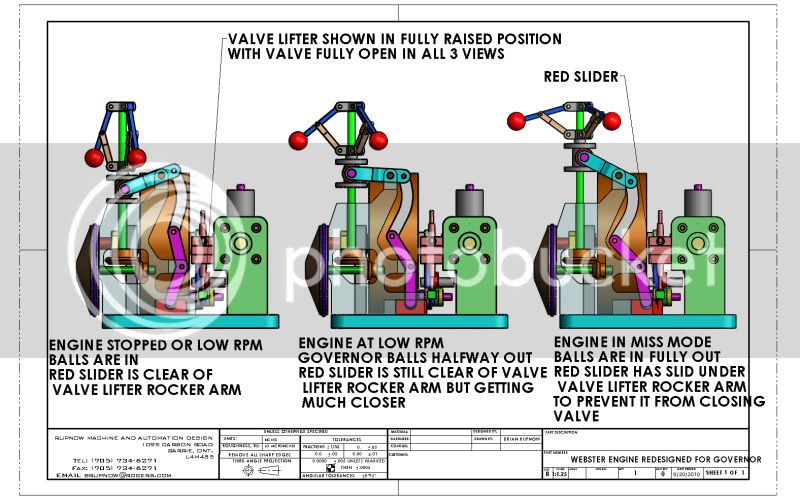

Hah---No worries! Runs like a champion. Good Lord, will it ever idle slowly now. And at about 1/4 throttle, if I shut off the ignition switch that new flywheel has enough momentum to turn the cranks shaft 5 to 7 times before all motion stops. If I reach in with my long screwdriver and hold the exhaust valve from closing, the engine will miss for 3 or 4 cycles, then if I let the exhaust valve close, it fires again and keeps on Running smoothly. This is very encouraging. Next thing required will be some more in depth design work to set up the flyball governor properly.