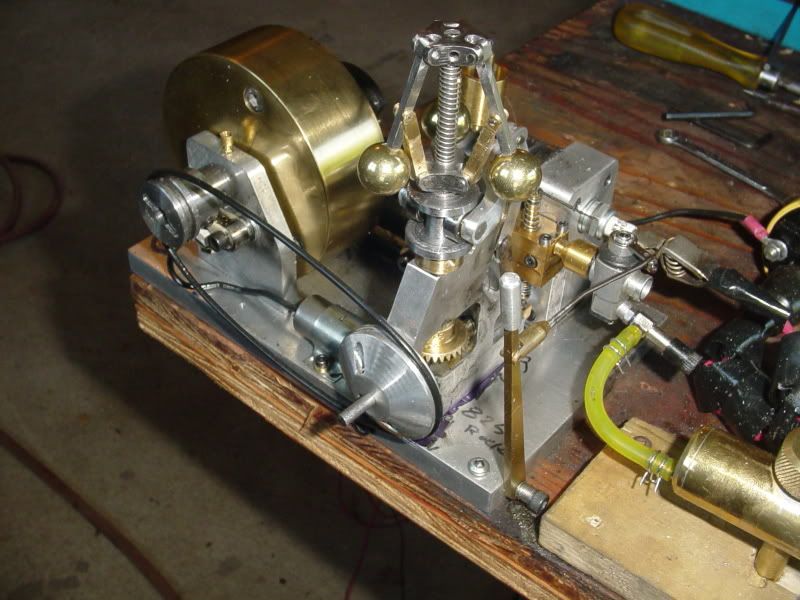

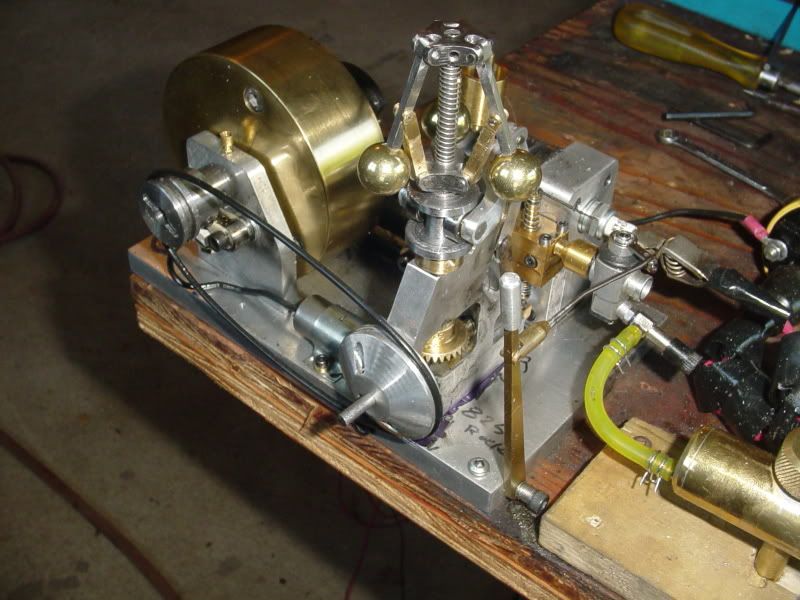

Nick---There is a 1:2 ratio on the bevel gear. The stempost of the governor will turn at 1/2 the speed of the crankshaft, IF I use a 1:1 ratio on the drive pulleys. The only reference I have is the Silver Angel I.C. engine, on which the governor stempost IS the camshaft, so turns at exactly 1/2 the crankshaft speed. I know there may be a lot of screwing about with the governor spring. That is why I attached the top yoke with set screws instead of silver soldering it in place. The way it is now, I can very quickly pull the top yoke off if I have to change springs.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Webster I.C. redesigned as hit and miss----

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Dang!!! Still no setscrews. I sure would like to try this thing out.

So chaps, here it is!!! The video I promised earlier, driving the governor with my variable speed drill. It has quieted down a lot after 10 minutes of continuous running. The action of the governors and lever mechanism works exactly like I had anticipated. I'm not certain that turning the Webster engine into a Hit and Miss will be succesfull, but the governor itself is indeed a success.----Brian

Hey, way back on the 16th I bought up the notion that modulating the exhaust valve wasn't gonna get it done. All I got was slammed. Now the same idea is fronted by some Johnny-come-lately and he's deemed brilliant. What's up with that? Give me some credit too. I should have patented the idea.

Good point JPeter!

I don't think you were slammed, I just don't think what you said was fully taken in until somebody else mentioned it and explained it a bit more. I think I skipped over your post at the time without having a think about what you were saying - the valve opening / closing needs to be digital.

I agree what's happened is exactly what you suggested though!

Credit where credit's due, good idea but don't get worked up about it, think it got missed in the excitement!

Nick

I don't think you were slammed, I just don't think what you said was fully taken in until somebody else mentioned it and explained it a bit more. I think I skipped over your post at the time without having a think about what you were saying - the valve opening / closing needs to be digital.

I agree what's happened is exactly what you suggested though!

Credit where credit's due, good idea but don't get worked up about it, think it got missed in the excitement!

Nick

Thanks.

I like the current plan. It's gonna have a lot of "monkey motion" which I find pretty pleasing in a hit'n miss. One addition you might consider adding though is making the slot in the block kinda large so the finger fits with some slop. Slop would allow the engine to coast for a while before the governor kicks it back in. The amount of slop could be controlled by a set screw in one of the two sides of the sliding block (to adjust the width of the slot). I've got a zero-six design built that'll coast 16 revolutions for every fire. I like em when they coast a lot.

I like the current plan. It's gonna have a lot of "monkey motion" which I find pretty pleasing in a hit'n miss. One addition you might consider adding though is making the slot in the block kinda large so the finger fits with some slop. Slop would allow the engine to coast for a while before the governor kicks it back in. The amount of slop could be controlled by a set screw in one of the two sides of the sliding block (to adjust the width of the slot). I've got a zero-six design built that'll coast 16 revolutions for every fire. I like em when they coast a lot.

Jpeter---To be honest, I didn't know what you meant by "modulating" the exhaust valve. There was no intent to slam you. I did have some concerns that gradually opening the exhaust valve would create issues, that was why I mentioned it. As far as clearance on the sliding finger, It has about .003" clearance now. Since I am truly breaking new ground here (for me anyways), its easier to take a bit more metal off than to put it back on. I'll try it this way first and see what happens. I don't as a rule slam people. I've been slammed enough myself that I know it doesn't feel very good. (Boo Hoo). Sometimes I don't respond to a post if I really don't know what was being said, thats all.---Brian

So, here we are, all ready to rock and roll, and wouldn't you know it----I don't have an o-ring the right length, and the place where I buy them isn't open untill Monday!!!! If I manually lift the balls (Nevermind ya filthy bugger), the engine does miss. Now I wait untill Monday to see if it works.

IT WORKS!!!! IT WORKS!!!! I just had the brainwave of holding a third small pulley on a shaft in place as a belt tensioner while the engine was running. As soon as the governor began to rotate, the entire "hit and miss" cycle happened just as I had hoped it would. Its going in and out of hit and miss mode quite rapidly, which indicates that I need a stronger spring on the stempost, but it is definitly operating as a hit and miss engine!!! YIPEEEE!!! I will get a correct size o-ring and a slightly stronger spring on Monday, and get a video up.---Brian

Now I have to put my thinking cap on and think on this for a while. Wife and I just sat on the back deck, under beautifull sunshine, 85 degrees F and drank a bottle of Australian wine, Yellowtail Shiraz---MMMMmmmmmm. Oh yes---I was thinking---the engine starts well, revs up to midrange speed, the governor balls fly out at what I would deem an "appropriate time" and then the engine goes into "miss" mode. The "miss" mode is very brief, perhaps one or two full engine revolutions, then the engine slows enough for the balls to pull in and start the engine firing again. This rapid cycle between firing and missing is what I want to correct. This, if I remember my engineering lessons from the distant past, is called "Hysteresis". I want the governor to engage exactly as it does now, in the RPM range it does now. However, I want more of a time lag between the engagement of the "exhaust valve lockout" and the disengagement of it. (This will give more "missing" cycles between when it starts to miss and stops missing ). I don't think a stronger governor spring would give this effect. All it would do is increase the point at which the RPM range got high enough to force the balls into the "full out" position ----and it would also shorten the time span of the 'miss" cycle proportionally, because the stronger spring would retract the balls sooner. It seems to me that perhaps the secret lies in the way the bottom lever engages with the slot in the top of the "exhaust valve lockout". Right now, it engages pretty well 1:1---That is to say, for every increment of movement of the lever, there is an equal increment of movement in the "exhaust valve lockout" (the red thing in the cad model). Perhaps if I were to widen the slot in the "exhaust valve lockout", on the side away from the rocker arm, then the exhaust valve lockout" would still engage at the same time, but there would be more of a delay before it disengaged, because the lever would have to move though a "dead space" before it came in contact with the other end of the slot in the "exhaust valve lockout" and caused it to completely withdraw from under the engines rocker arm. If you can understand this, and agree or disagree, let me know please.----Brian

Since I had a heavier spring here, (.023 dia. wire as opposed to .019 wire) I went ahead and tried the heavier spring approach. It didn't work. In fact, with the current pulley set up, the balls didn't create enough centrigugal force to overcome the springs strength to make the balls fly out far enough to even begin the "hit and miss" cycle. I had to try. In the wonderfull world of "Try it and see if it works" engineering, you have to try every approach available.

Yes Brian, a wider slot in the "exhaust valve lockout" would introduce some (needed) hysteresis in the system. Another area to add hysteresis would be introducing additional friction between the exhaust valve lever and the block that keeps it from closing. Friction enough that the balls would need to do some work also when they´re going down, pulling the block back. If the surfaces on both the block and the downside of the lever are very smooth (and I believe they are - you would have made sure they are polished ;D ), they might actually benefit from some deep scratches and punch marks. It´s not often that an engine would benefit from additional friction - but this is the exception to the rule.

Lovely governor, BTW. And works really fine.

Lovely governor, BTW. And works really fine.

Hmmm-here's food for thought---Perhaps I need a lighter spring. The balls would fly out and engage sooner, but they wouldn't be so quick to retract the "exhaust valve lockout" either---

Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

Brian....

We're both slogging through the same adjustment, it seems. My little engine is also in "rapid cycle" mode but is definitely doing the hit and miss thing.

After playing with various settings, I've come to the conclusion that I need to "soften" the spring a bit to allow the balls to have more effect (ie. stay expanded longer) while at full expansion. It appears I'll also have to clearance the expansion joints to give more room for adjustment to the spring retainer. Small cramped work space is making it an interesting bit of fitting.

Not sure if there is a direct correlation with your design since mine is mounted directly on the crank but thought I'd share the direction I'm headed.

Steve

We're both slogging through the same adjustment, it seems. My little engine is also in "rapid cycle" mode but is definitely doing the hit and miss thing.

After playing with various settings, I've come to the conclusion that I need to "soften" the spring a bit to allow the balls to have more effect (ie. stay expanded longer) while at full expansion. It appears I'll also have to clearance the expansion joints to give more room for adjustment to the spring retainer. Small cramped work space is making it an interesting bit of fitting.

Not sure if there is a direct correlation with your design since mine is mounted directly on the crank but thought I'd share the direction I'm headed.

Steve

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 148

- Views

- 21K