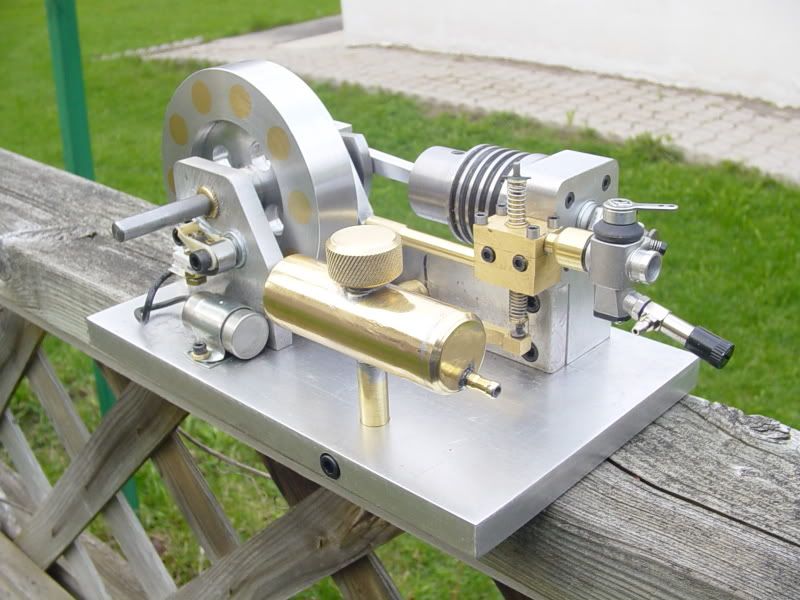

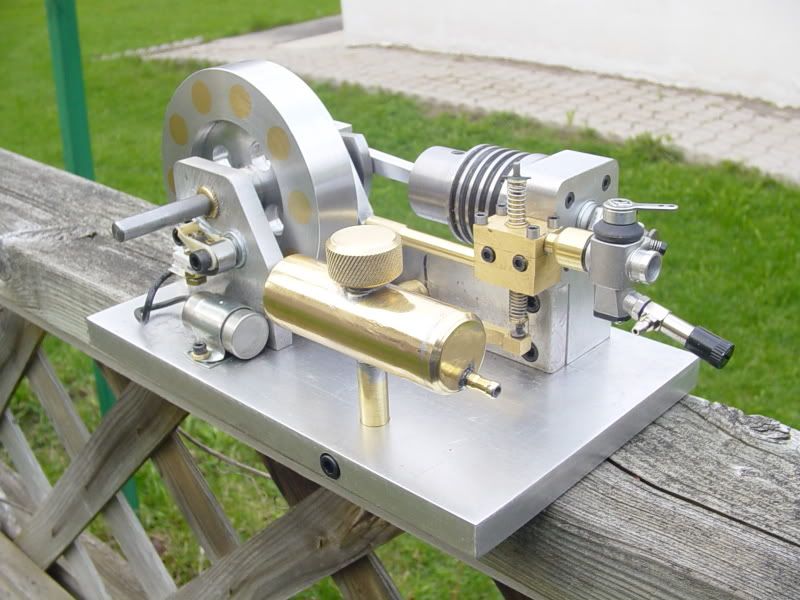

Last year, I built a Webster I.C. engine from plans that I downloaded off the internet. http://www.homemodelenginemachinist.com/index.php?topic=8388.0 They are a great set of plans, and I am most impressed with the engine. I haven't machined much lately. Its summertime, and the hotrod cruise/show season is in full swing, and my (other) hobby, a 1931 model A roadster pickup has been filling my spare time. BUT----I 'bin thinkin'------

I think hit and miss engines are kinda neat. I built the Chuck Fellows hit and miss steam engine, and it performed well. Once I have built an engine, worked out the "bugs", and have it running well, its just not that interesting anymore. (after you've showed your wife, your kids, your grandkids, and any unsuspecting friends or neighbours that drop by---)

I've been looking at the Webster, and thinking---The thing that makes a hit and miss engine hit and miss is a function of some type of centifugal governor energizing a mechanism to hold the exhaust valve of its seat at high RPMs untill the engine slows down, then the exhaust valve is allowed to seat once more and the engine fires again untill the RPMs pick back up again.

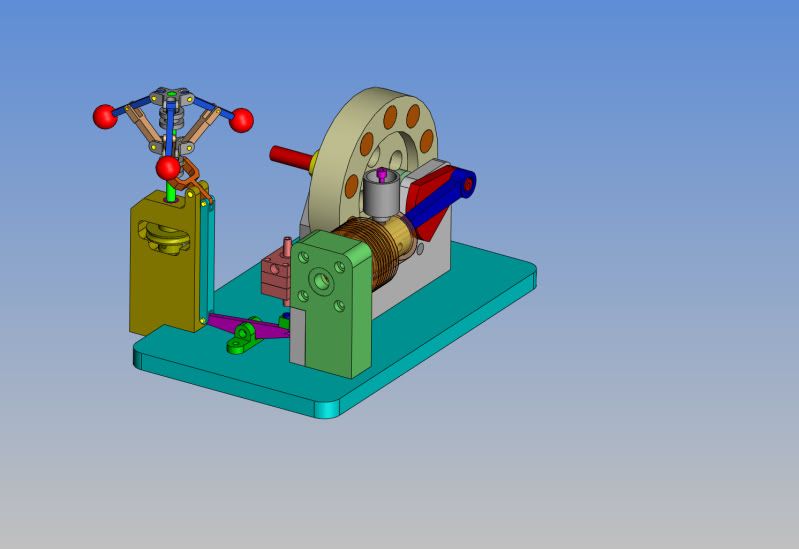

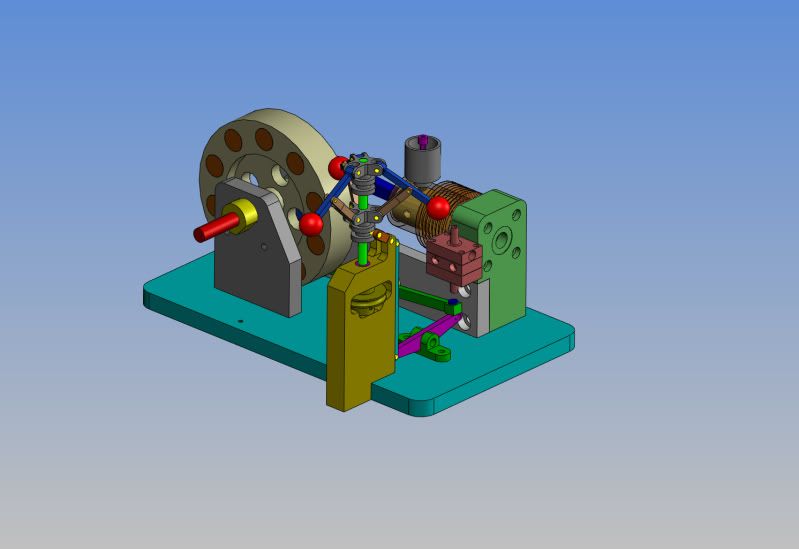

Now if I was to move the gas tank, and run a jackshaft in a set of pillow blocks in the spot where the gas tank now occupies, and drive it with a chain drive, and the jackshaft had a set of bob-weights on it and a lever---and the exhaust valve lifter is right there close at hand---Hmmmmm----Food for thought----

I think hit and miss engines are kinda neat. I built the Chuck Fellows hit and miss steam engine, and it performed well. Once I have built an engine, worked out the "bugs", and have it running well, its just not that interesting anymore. (after you've showed your wife, your kids, your grandkids, and any unsuspecting friends or neighbours that drop by---)

I've been looking at the Webster, and thinking---The thing that makes a hit and miss engine hit and miss is a function of some type of centifugal governor energizing a mechanism to hold the exhaust valve of its seat at high RPMs untill the engine slows down, then the exhaust valve is allowed to seat once more and the engine fires again untill the RPMs pick back up again.

Now if I was to move the gas tank, and run a jackshaft in a set of pillow blocks in the spot where the gas tank now occupies, and drive it with a chain drive, and the jackshaft had a set of bob-weights on it and a lever---and the exhaust valve lifter is right there close at hand---Hmmmmm----Food for thought----