- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

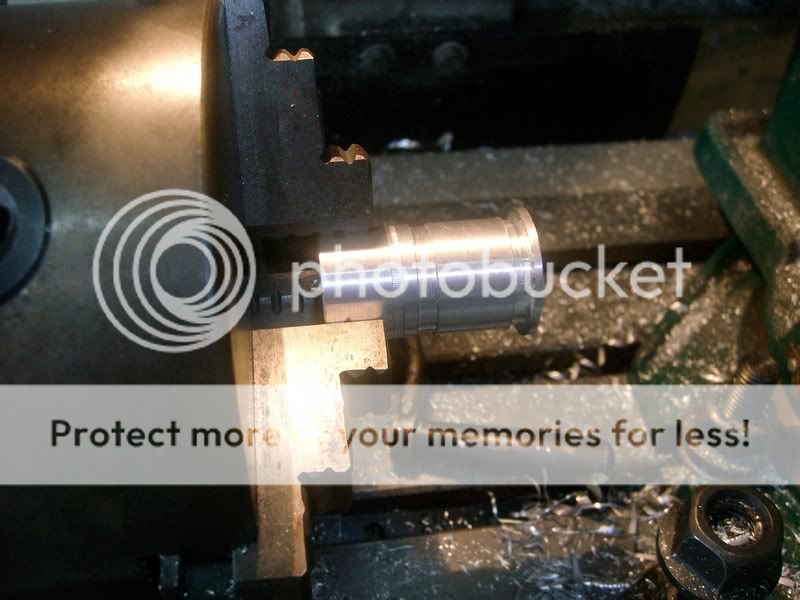

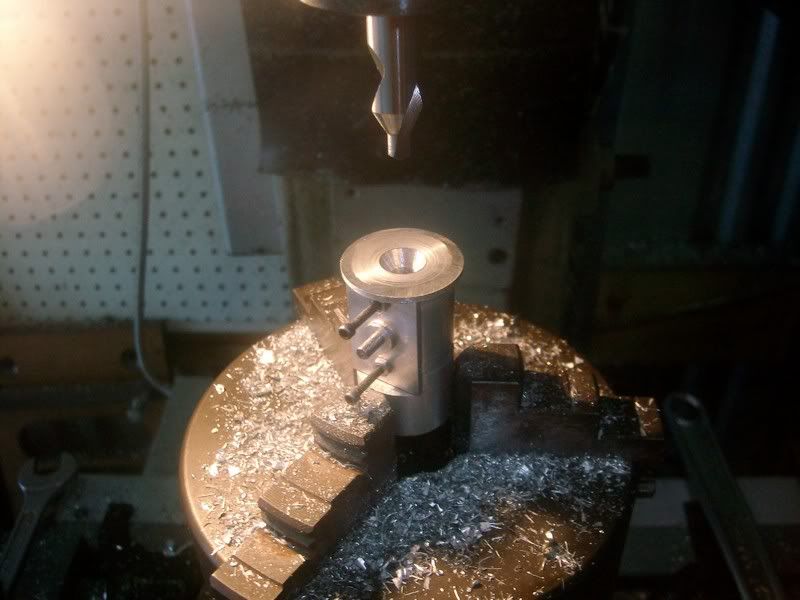

Made a valve today and did a temporary install to help in choosing the springs.

The valve seats are not done, so it will sit a little higher and of course the rockers need to be neatened up down the track a bit.

I think id like to go just a little larger then the one shown.

The valve seats are not done, so it will sit a little higher and of course the rockers need to be neatened up down the track a bit.

I think id like to go just a little larger then the one shown.