- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

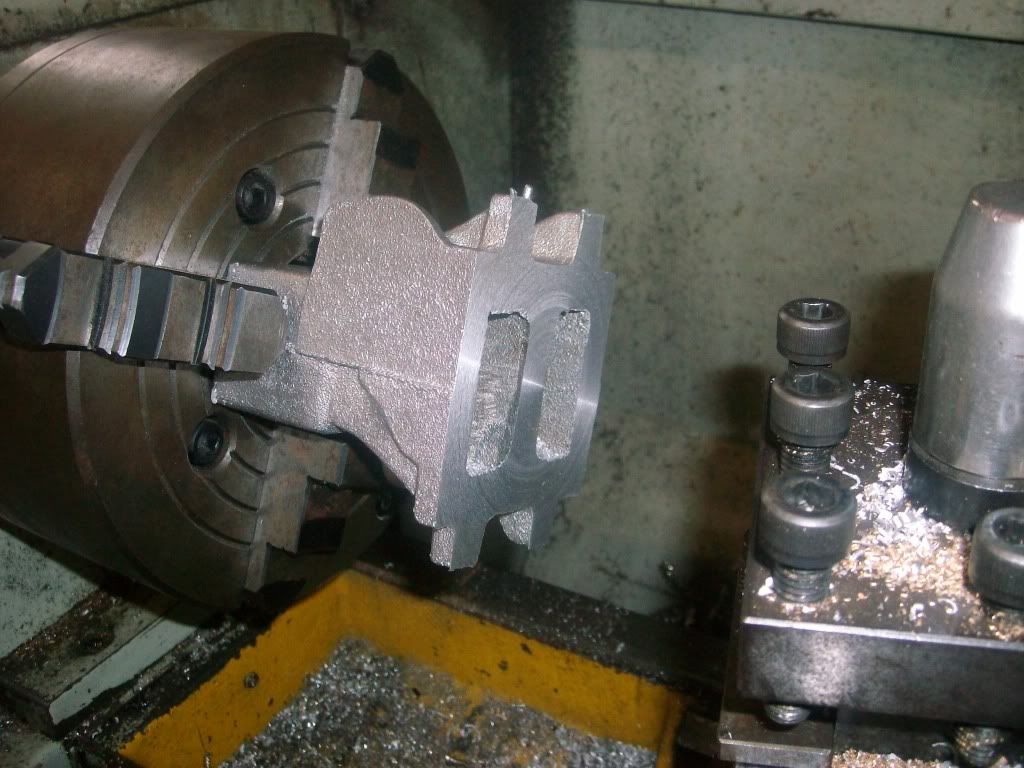

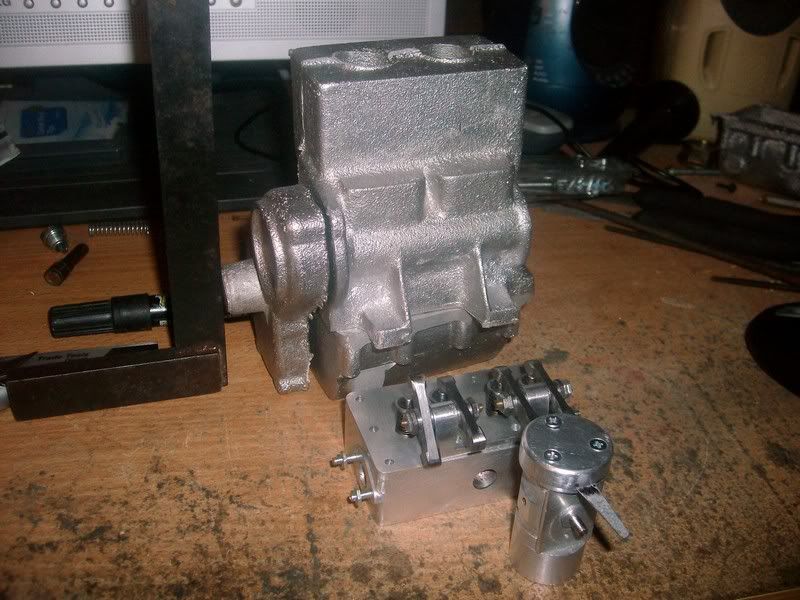

The carby has a spraybar going thru the slotted throttle and I will turn down the outside to a hourglass shape once its done internally.

I'm thinking now of using the chucking piece as a manifold adaptor so the standard 1831 inlet will bolt right up.

I may do this by milling a flat and drilling a 3/8 hole at 45 degrees to join up with the venturi and then blocking off the bottom hole and milling 45 degrees off the outside of the chucking piece for effect.

Pete

PS

I'm not sure what a compensating piston is or does Dave, but I don't think Ive got one :big:

I'm thinking now of using the chucking piece as a manifold adaptor so the standard 1831 inlet will bolt right up.

I may do this by milling a flat and drilling a 3/8 hole at 45 degrees to join up with the venturi and then blocking off the bottom hole and milling 45 degrees off the outside of the chucking piece for effect.

Pete

PS

I'm not sure what a compensating piston is or does Dave, but I don't think Ive got one :big: