Robin Mosedale

Member

My first post after watching for some time.

UK based.

I'd very much welcome guidance and moderation on ambition.

I've made steam engines for quite some time, both stationary, traction engines and railway locomotives.

I've never made an IC engine, being somewhat daunted.

I'd like to give it a go.

I've downsized my equipment over the years, following downscaling on engines.

I've a Warco WM180: with DRO's, 90mm centre height ~3.54"

Supplemented by a Peatol (Taig) CNC micro Mill, with long bed and manual rotary control as well as CNC.

The usual machine tool accessories, but I've yet to decide on rotary table, for the Mill rather than the lathe methinks.

I've searched the usual sources of engines.

I'd really like to keep it simple, anticipating enough new challenges with camshafts and ignition.

Ideally I'd like a twin, boxer, or whatever, but probably more realistic to start with a single.

I'm at a loss:

Those available from Hemmingway seem wonderously aged. The recommended beginners is the Westbury Kiwi mk2 harks back to 1935, revised upwards. The castings cost more than purchasing a modern 4 stroke.

The Kiwi Mk2 - E T Westbury - hemingwaykits.com

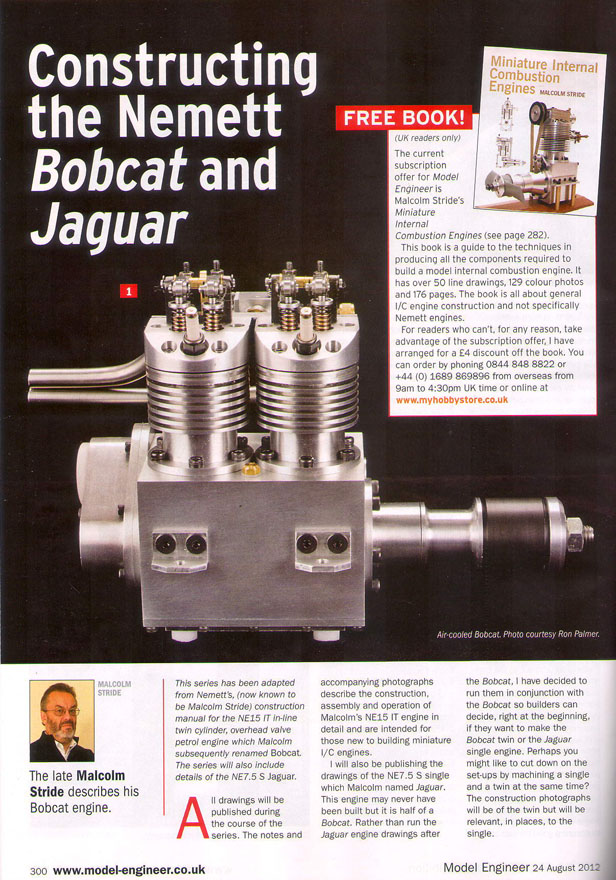

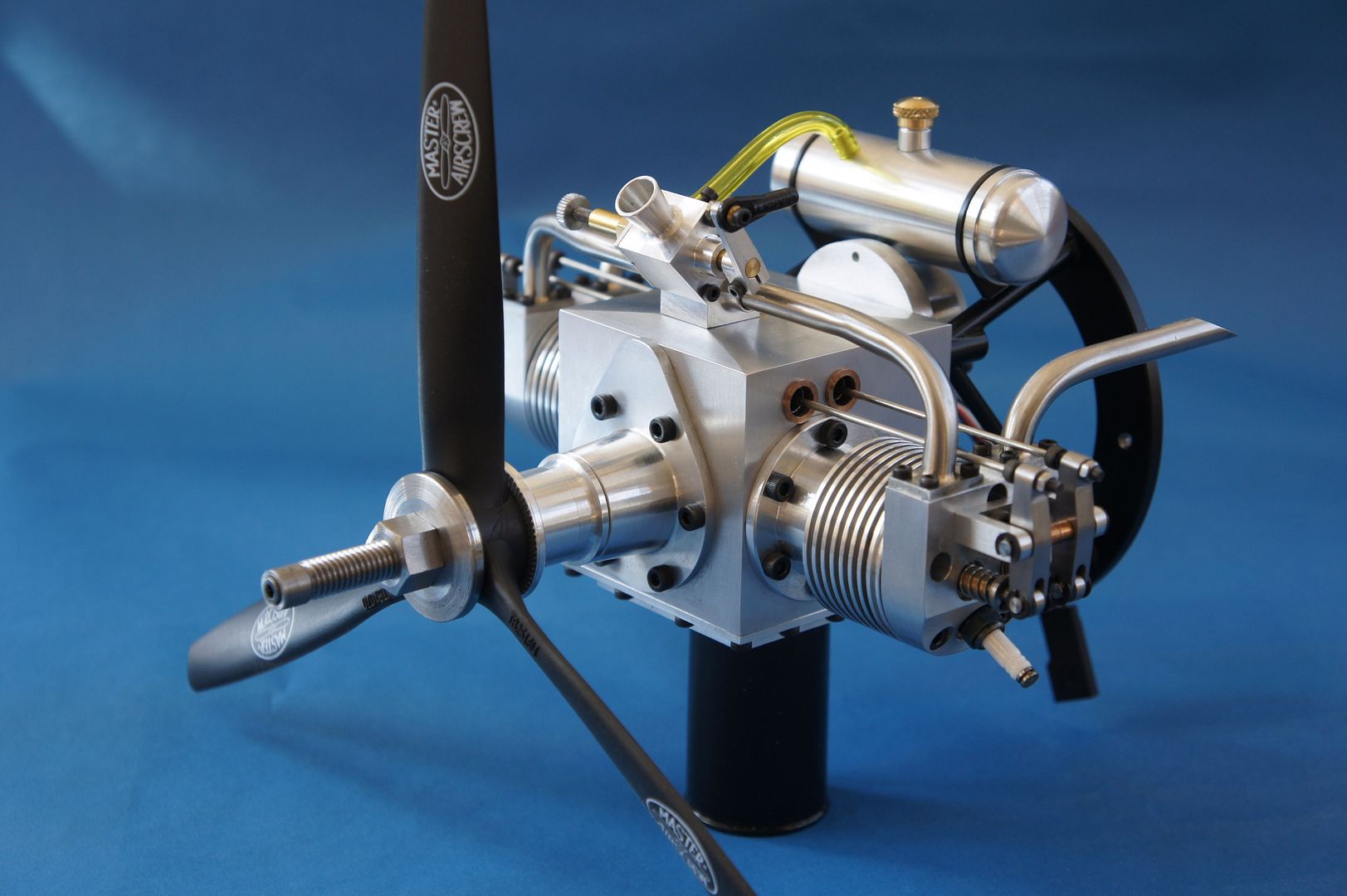

I think I've seen a couple of boxer twins, machined from stock.

Drawings are fine. However, drawings supplemented by guidance and machining notes would be a huge help for a first 4 stroke fabrication. Too many jigs or tooling manufacture would put me off.

Simple rather than elegance or beauty.

I'd really welcome some guidance as to where to start, and source of drawings, castings, guides.

Hope that you can start me off

Robin

UK based.

I'd very much welcome guidance and moderation on ambition.

I've made steam engines for quite some time, both stationary, traction engines and railway locomotives.

I've never made an IC engine, being somewhat daunted.

I'd like to give it a go.

I've downsized my equipment over the years, following downscaling on engines.

I've a Warco WM180: with DRO's, 90mm centre height ~3.54"

Supplemented by a Peatol (Taig) CNC micro Mill, with long bed and manual rotary control as well as CNC.

The usual machine tool accessories, but I've yet to decide on rotary table, for the Mill rather than the lathe methinks.

I've searched the usual sources of engines.

I'd really like to keep it simple, anticipating enough new challenges with camshafts and ignition.

Ideally I'd like a twin, boxer, or whatever, but probably more realistic to start with a single.

I'm at a loss:

Those available from Hemmingway seem wonderously aged. The recommended beginners is the Westbury Kiwi mk2 harks back to 1935, revised upwards. The castings cost more than purchasing a modern 4 stroke.

The Kiwi Mk2 - E T Westbury - hemingwaykits.com

I think I've seen a couple of boxer twins, machined from stock.

Drawings are fine. However, drawings supplemented by guidance and machining notes would be a huge help for a first 4 stroke fabrication. Too many jigs or tooling manufacture would put me off.

Simple rather than elegance or beauty.

I'd really welcome some guidance as to where to start, and source of drawings, castings, guides.

Hope that you can start me off

Robin