- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

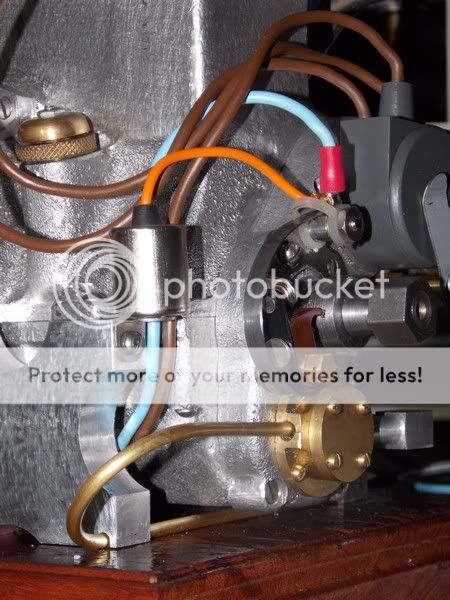

I ended up grinding a old drill bit square on the end to finish of the hole and then Had all sorts of fun and games getting the thread right up to the blind hole.

Still, not a bad arvos work.

The Tell tale will protrude through this end Cap

Pete

Still, not a bad arvos work.

The Tell tale will protrude through this end Cap

Pete