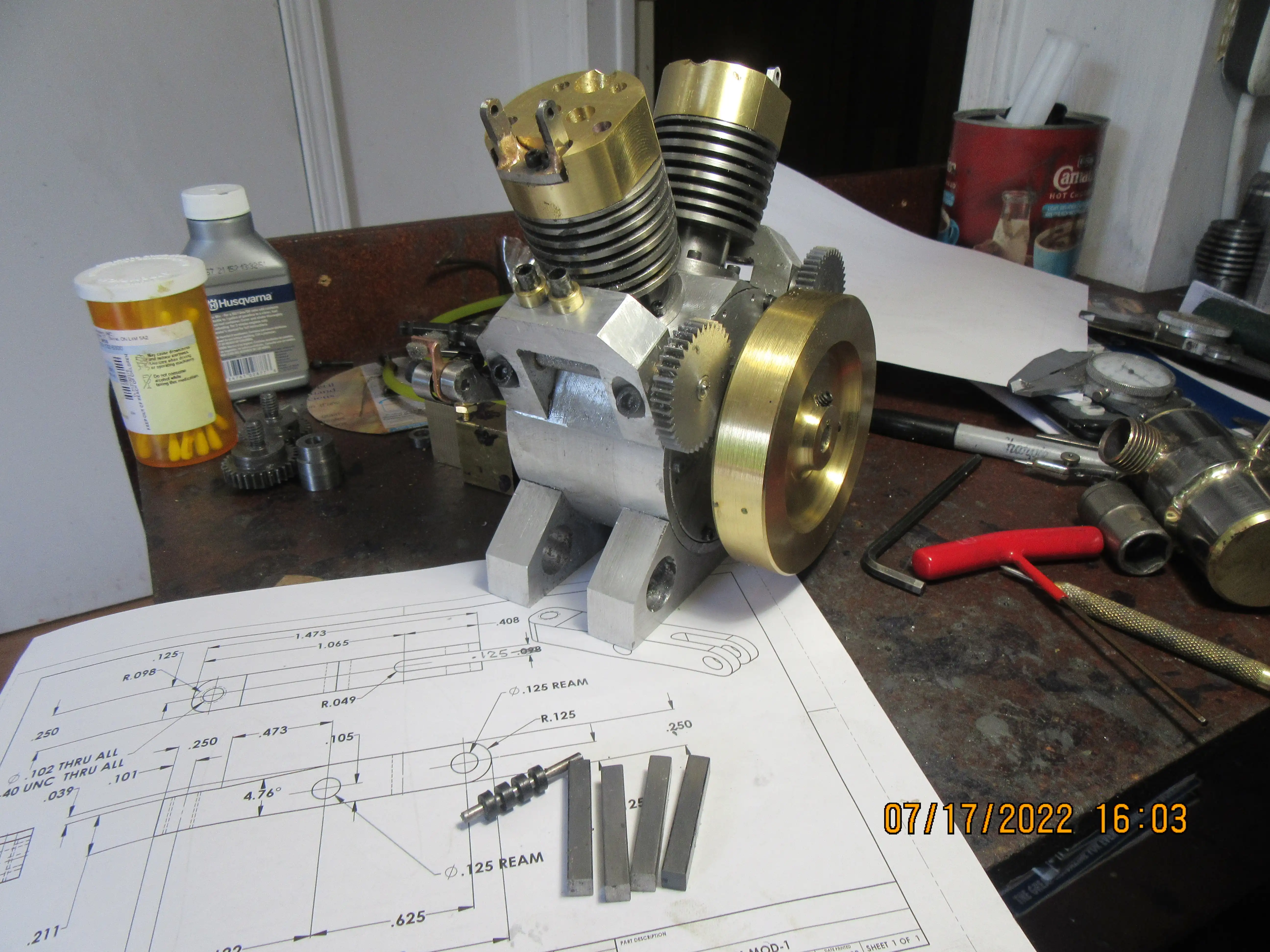

It fits!!!

I'm curious - why not silver-solder the tank-ends as well ? Do ferrous metals and brass not stick together when silver-soldered ?It is all ferrous metal and all silver soldered except for the two brass ends which will be held in place by J.B. weld.

Enter your email address to join: