Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

Hello Ralph,

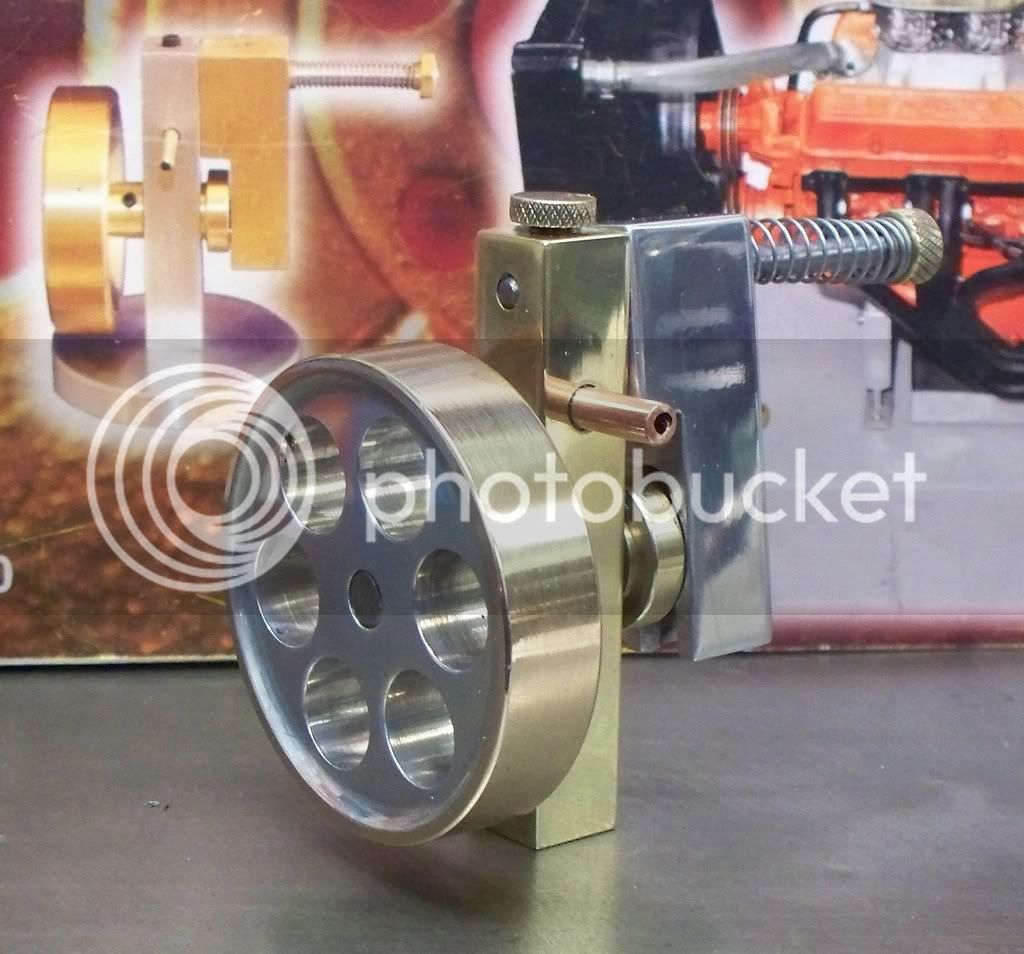

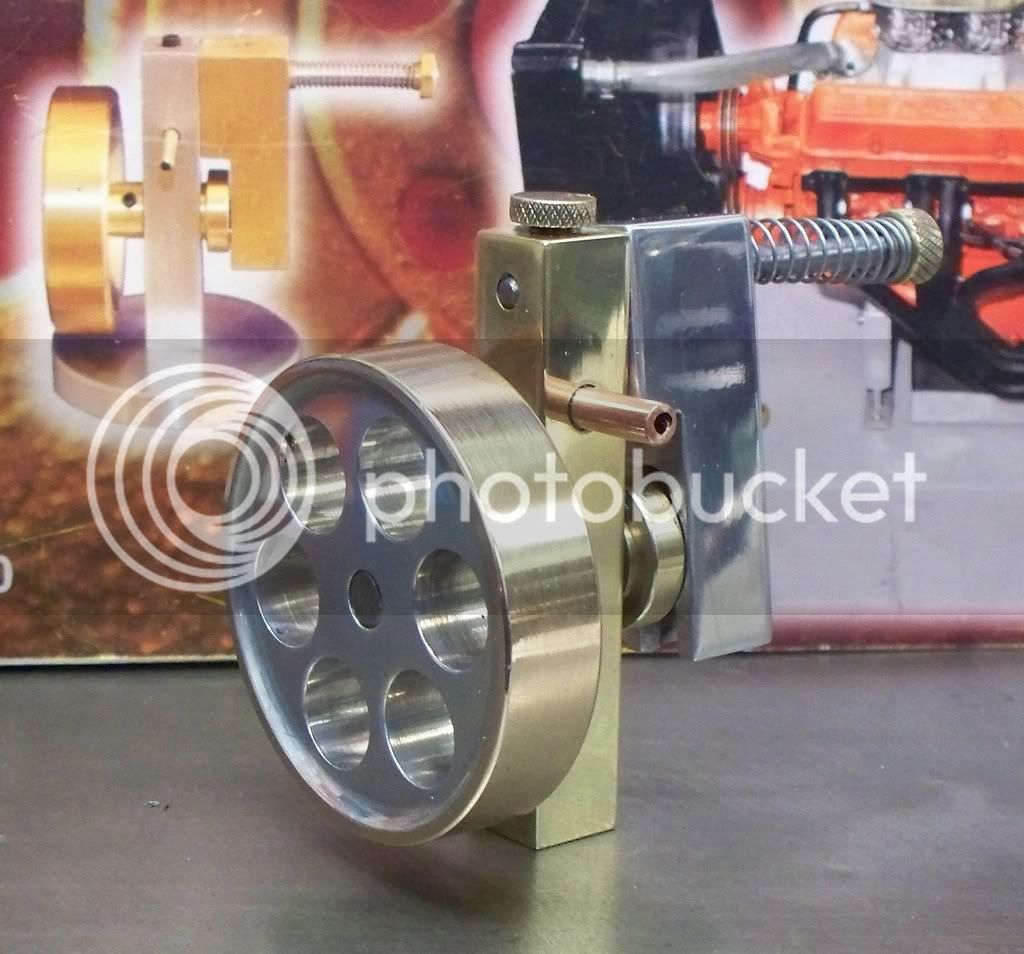

Yes I am going for shiny. I did try to do the whirly thingy (see photo below) but even though I tries different materials to make the swirls, I didn't see any thing I liked. It may be because they are so small an engine? I will have a go at the effect but not for these wobbler's.

I also finished the second engine to working stage and used it to trial the air supply that will allow the recipients to have the engines on their desks (if that is what they want!) and allow them to work. I don't know how long a cylinder of air will last but running the second engine it didn't seem to take a lot...and that should be even more efficient when the supply is correctly connected.

I spent the session sorting the second engine and giving a first polish up on the first engine (see photo below)

I have put a short video below of the second engine and you can see the control available (which I was pleased with) and there is a photo at the bottom after its first polish. There will be a final polish later. I was surprised at the efficiency of the small ultrasonic cleaner (photo below)and the amount of dirt that came from a relatively clean set of parts.

Finally I have decided on the base for the engines(photo below). I was hoping to have some sort of cover for the air cylinder but the only cylinders I could purchase in my area are very very long! SO I have changed my mind and they can store the cylinders wherever and bring them out when they want to see the little engines run.......

First the photo's...

The base will come from the items in this photo. I hope to turn the mahogany to fit inside the brass, somewhat like a wheel (the wood) and a tyre (the brass). I will see how they turn out before making a final decision.

And finally the Video, remember it is only showing the variability of control from the air cylinder supply....

[youtube=425,350]<object width="425" height="344"><param name="movie" value="http://www.youtube.com/v/SKSQsIzS1-o&hl=en&fs=1"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/SKSQsIzS1-o&hl=en&fs=1" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="425" height="344"></embed></object>[/youtube]

Yes I am going for shiny. I did try to do the whirly thingy (see photo below) but even though I tries different materials to make the swirls, I didn't see any thing I liked. It may be because they are so small an engine? I will have a go at the effect but not for these wobbler's.

I also finished the second engine to working stage and used it to trial the air supply that will allow the recipients to have the engines on their desks (if that is what they want!) and allow them to work. I don't know how long a cylinder of air will last but running the second engine it didn't seem to take a lot...and that should be even more efficient when the supply is correctly connected.

I spent the session sorting the second engine and giving a first polish up on the first engine (see photo below)

I have put a short video below of the second engine and you can see the control available (which I was pleased with) and there is a photo at the bottom after its first polish. There will be a final polish later. I was surprised at the efficiency of the small ultrasonic cleaner (photo below)and the amount of dirt that came from a relatively clean set of parts.

Finally I have decided on the base for the engines(photo below). I was hoping to have some sort of cover for the air cylinder but the only cylinders I could purchase in my area are very very long! SO I have changed my mind and they can store the cylinders wherever and bring them out when they want to see the little engines run.......

First the photo's...

The base will come from the items in this photo. I hope to turn the mahogany to fit inside the brass, somewhat like a wheel (the wood) and a tyre (the brass). I will see how they turn out before making a final decision.

And finally the Video, remember it is only showing the variability of control from the air cylinder supply....

[youtube=425,350]<object width="425" height="344"><param name="movie" value="http://www.youtube.com/v/SKSQsIzS1-o&hl=en&fs=1"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/SKSQsIzS1-o&hl=en&fs=1" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="425" height="344"></embed></object>[/youtube]