Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

You may call me a cheapskate but whilst I was away from home I thought that a simple wobbler type engine would make a nice Christmas present. Since I was making one it would be just as easy to make two!

The plans for this particular engine come from Model Engine Builder (issue 1) and are simple to make. I thought they would be nice to be seen running and I intend to try and run them using a regulated supply from air brush type cylinders hidden some way on a base (perhaps a brass cylinder?). Anyway a picture is better that a thousand of my words so below is the progress made so far.

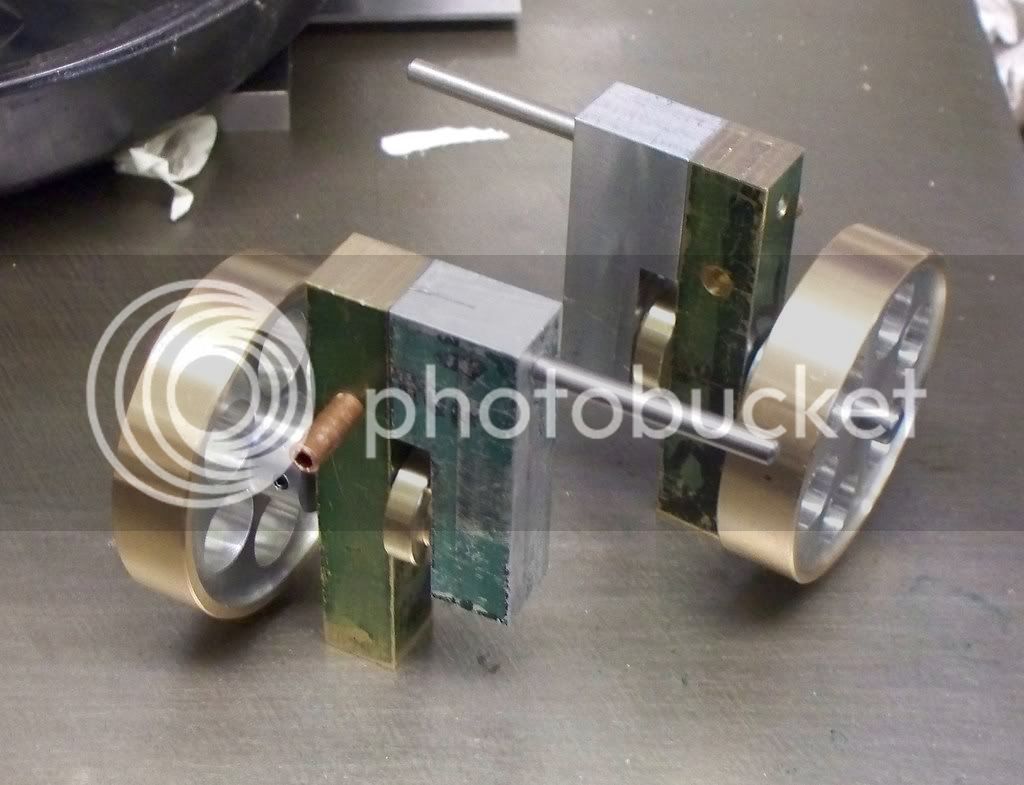

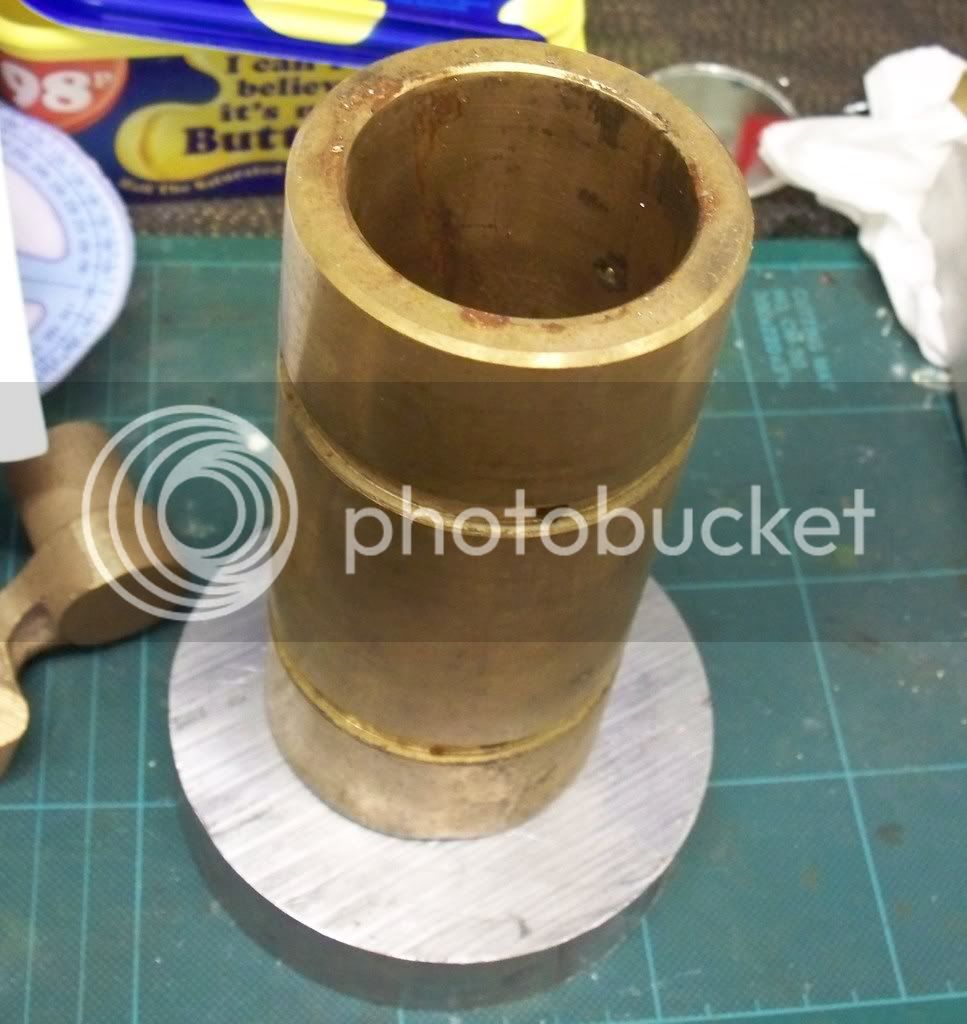

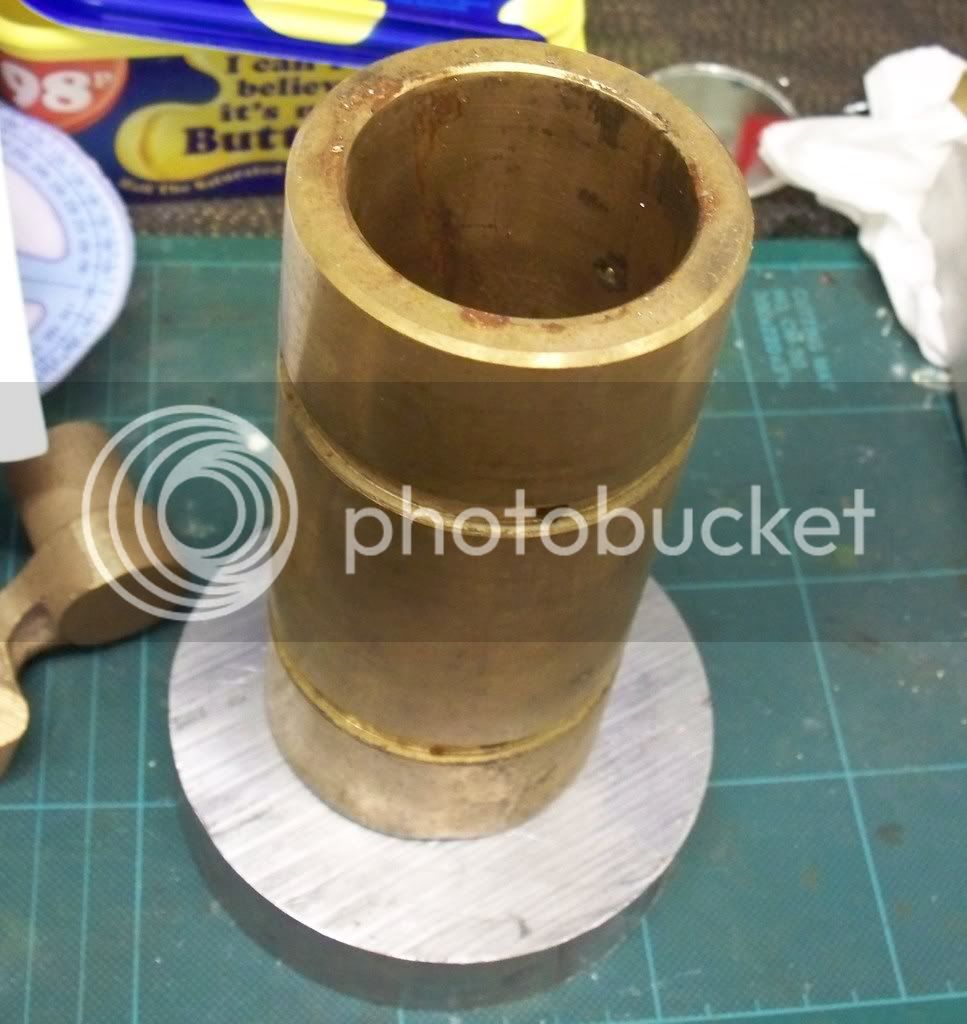

1. Some 'scrap' brass that will form the outside of the flywheels

2. Aluminium for the inside of the flywheels

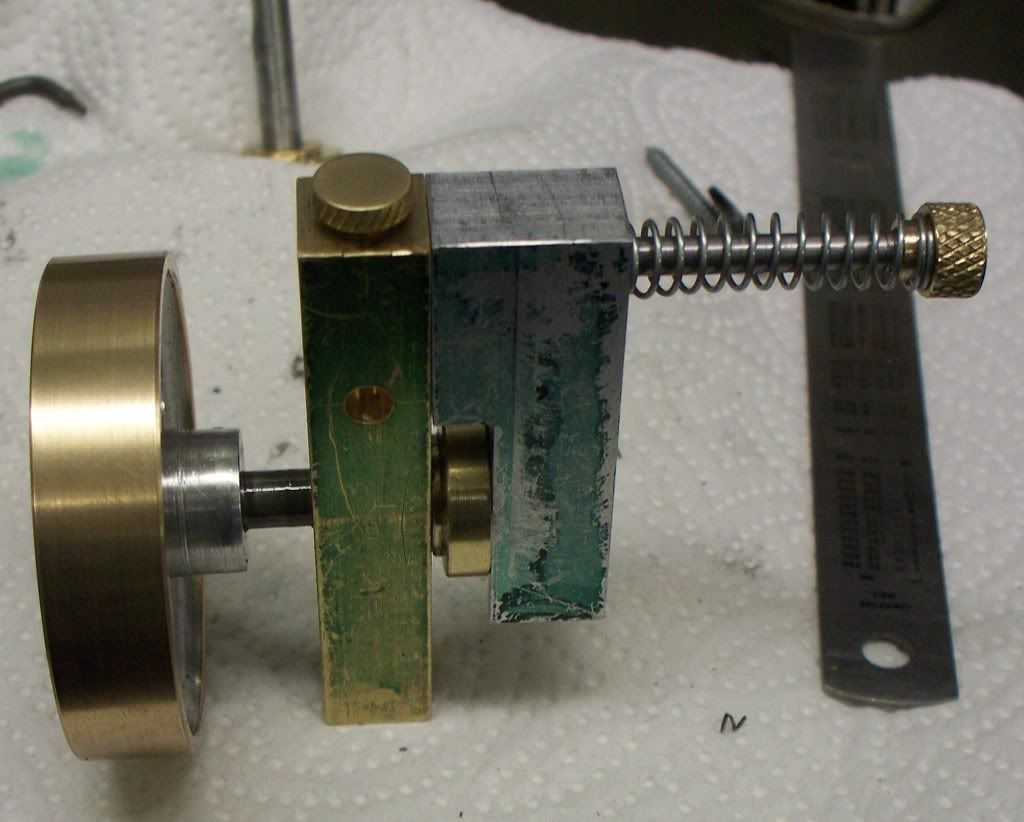

3. Making the two flywheels as one piece....

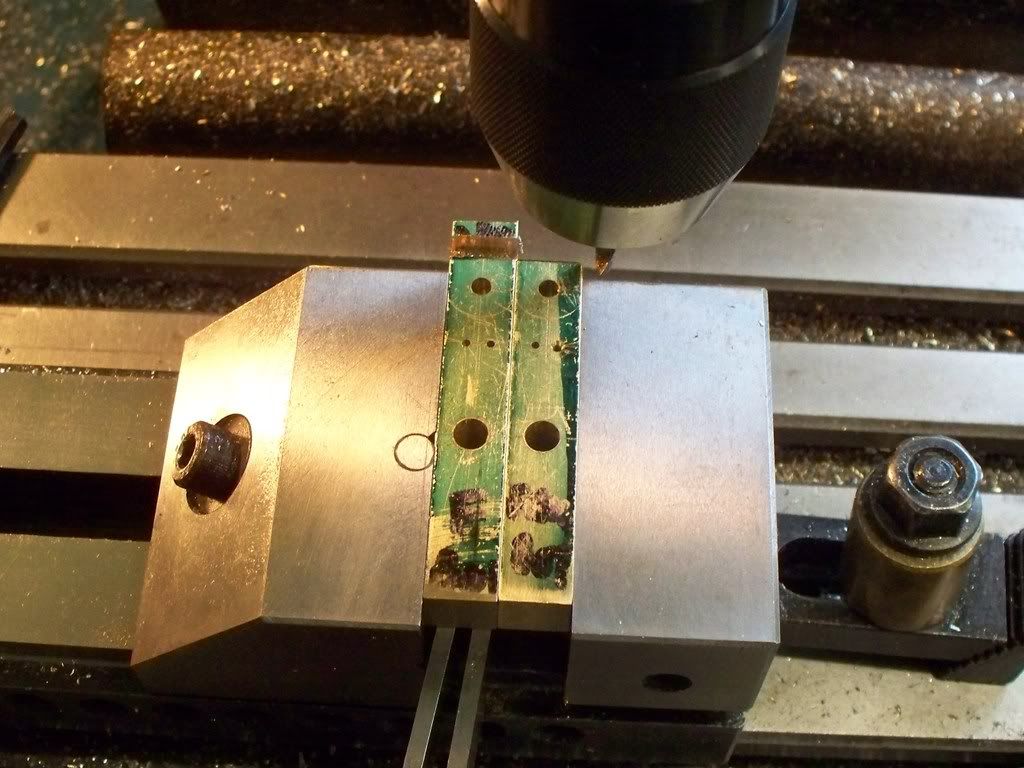

4. Marking out one of the pillars....

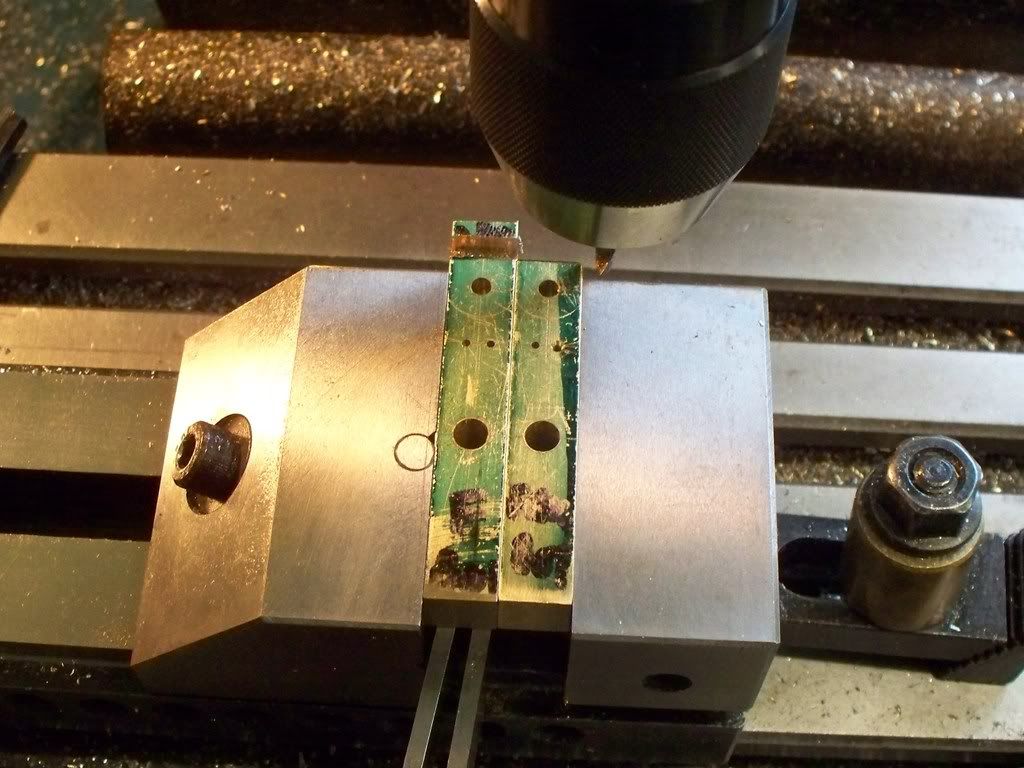

5. Drilling both pillars at the same time is not much more effort than one........

More tomorrow......(I hope...)

The plans for this particular engine come from Model Engine Builder (issue 1) and are simple to make. I thought they would be nice to be seen running and I intend to try and run them using a regulated supply from air brush type cylinders hidden some way on a base (perhaps a brass cylinder?). Anyway a picture is better that a thousand of my words so below is the progress made so far.

1. Some 'scrap' brass that will form the outside of the flywheels

2. Aluminium for the inside of the flywheels

3. Making the two flywheels as one piece....

4. Marking out one of the pillars....

5. Drilling both pillars at the same time is not much more effort than one........

More tomorrow......(I hope...)