putputman

Senior Member

- Joined

- Nov 22, 2008

- Messages

- 600

- Reaction score

- 55

Feb 20 2010 -- I HAVE REMOVED ALL OLD PRINTS AND REPLACED THEM WITH REVISION "B" PRINTS. THEY SHOULD SHOW UP IN MY FIRST 6 POSTS. THERE IS ONE SET OF NOTES AND 21 PRINTS.

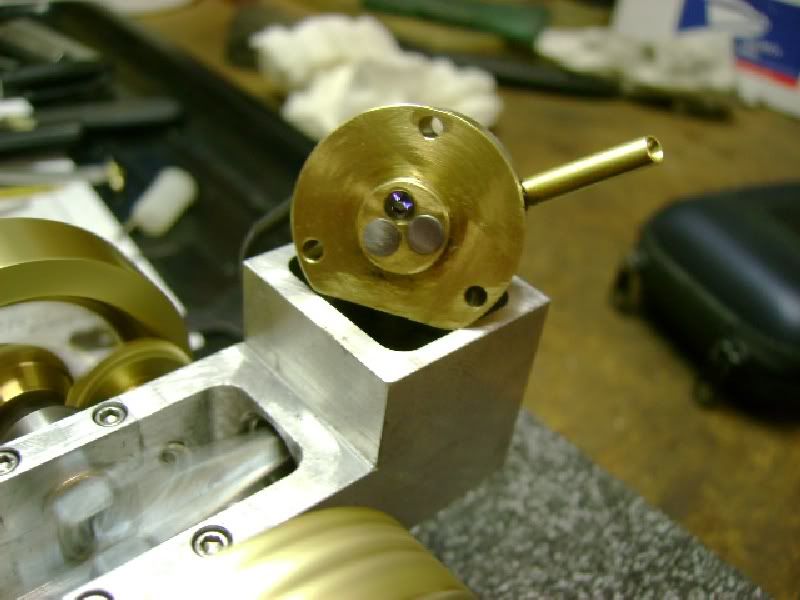

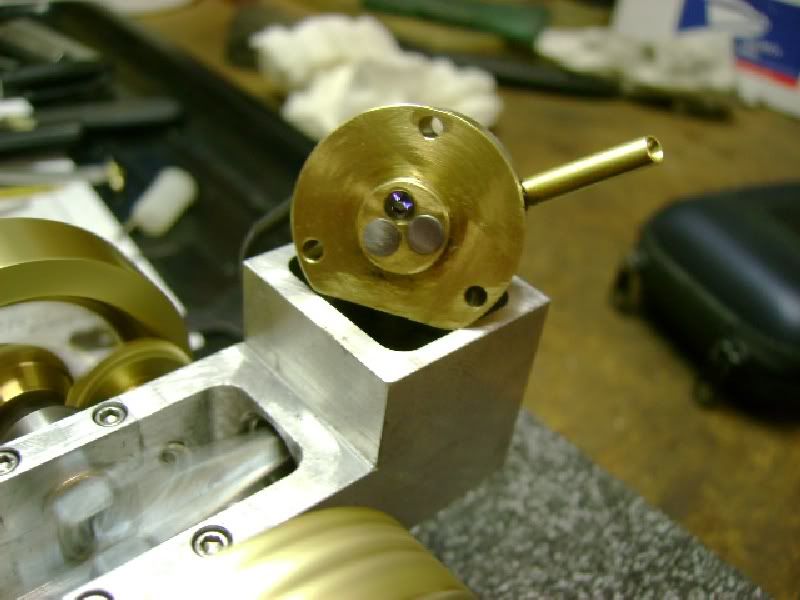

This is a tiny I.C. engine that I just completed. I first saw this engine at the LeSueur, MN. Pioneer Power Days last summer. A gentleman by the name of Jim, from Des Moines, IA. Had a couple small engines that that were beautifully built and run like a dream. Jim and I have had many conversations since we first met and he has provided me with build information talked me through several problems I had completing this engine. Jim, I can't thank you enough.

This is the smallest I.C. Engine that I ever tackled.

It has a 3/8 dia. Bore and a 1/2 inch stroke. Getting two valves and a spark plug in that small area proved to be quite a challenge.

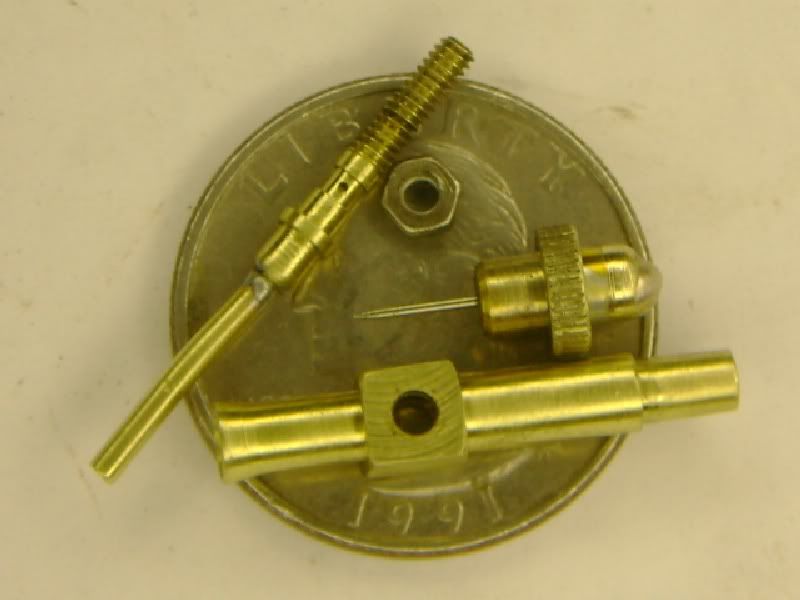

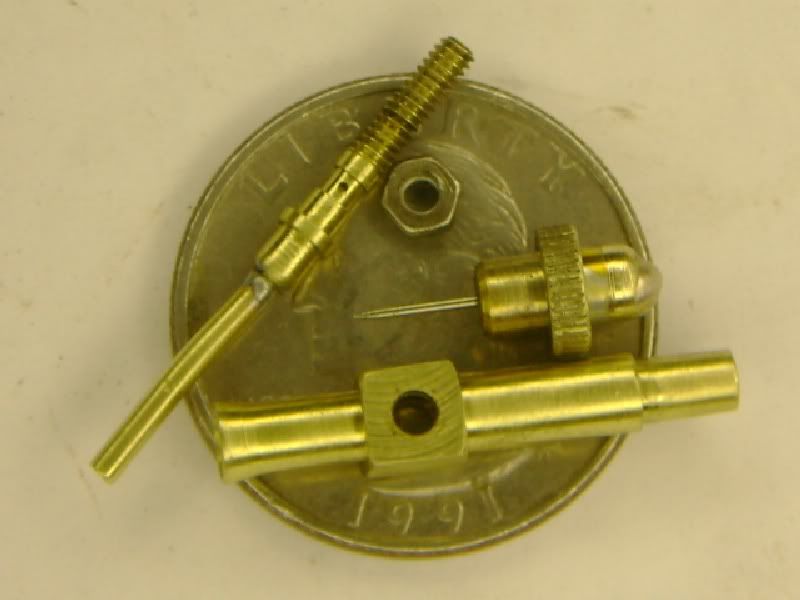

It was the first time I tried making a spark plug. The body was made from 12L14 with a Teflon insulator and .035 music wire electrode.

The fuel mixer was also quite small. The spray bar has .018 fuel inlet and a .020 cross hole. The needle is a .025 dia sewing needle.

Jim recommended using S/S Machine & Engineering for a CDI unit for the electrical end. Knowing absolutely nothing about CDI units, I contacted Roy Sholl, owner/operator of SS. I have to say that I have never worked with any supplier that has been as patient and helpful as Roy. I highly recommend him for anyone needing an ignition system for their models.

The CDI unit is very small and I was able to conceal it in the Corian base I made for this engine. The unit puts out a good spark. I ended up using a Hall Effect for my ignition.

Had a few problems getting the engine to run and stay running. I used an O-ring on the piston. The valves sealed OK. It took several tries to get the intake spring pressure correct. Once it started it run pretty good, but after a short time it would quit. I would have to choke the heck out of it to get it started again. After several runs, it wouldn't even start. I replaced the O-ring and it took off again. Apparently the finish in the bore was too rough and would ware out the O-ring quite fast. I put a good finish in the bore and haven't had a problem since.

This could be an ideal I.C. Engine for the people that have mini lathes & milling machines such as Sherline and Tieg.

View attachment Tiny I.C. Notes -- rev B.pdf

View attachment Tiny 1 Frame - rev B.pdf

View attachment Tiny 1A Crank Ret. -- rev B.pdf

View attachment Tiny 2 Gas Tank -- rev B.pdf

This is a tiny I.C. engine that I just completed. I first saw this engine at the LeSueur, MN. Pioneer Power Days last summer. A gentleman by the name of Jim, from Des Moines, IA. Had a couple small engines that that were beautifully built and run like a dream. Jim and I have had many conversations since we first met and he has provided me with build information talked me through several problems I had completing this engine. Jim, I can't thank you enough.

This is the smallest I.C. Engine that I ever tackled.

It has a 3/8 dia. Bore and a 1/2 inch stroke. Getting two valves and a spark plug in that small area proved to be quite a challenge.

It was the first time I tried making a spark plug. The body was made from 12L14 with a Teflon insulator and .035 music wire electrode.

The fuel mixer was also quite small. The spray bar has .018 fuel inlet and a .020 cross hole. The needle is a .025 dia sewing needle.

Jim recommended using S/S Machine & Engineering for a CDI unit for the electrical end. Knowing absolutely nothing about CDI units, I contacted Roy Sholl, owner/operator of SS. I have to say that I have never worked with any supplier that has been as patient and helpful as Roy. I highly recommend him for anyone needing an ignition system for their models.

The CDI unit is very small and I was able to conceal it in the Corian base I made for this engine. The unit puts out a good spark. I ended up using a Hall Effect for my ignition.

Had a few problems getting the engine to run and stay running. I used an O-ring on the piston. The valves sealed OK. It took several tries to get the intake spring pressure correct. Once it started it run pretty good, but after a short time it would quit. I would have to choke the heck out of it to get it started again. After several runs, it wouldn't even start. I replaced the O-ring and it took off again. Apparently the finish in the bore was too rough and would ware out the O-ring quite fast. I put a good finish in the bore and haven't had a problem since.

This could be an ideal I.C. Engine for the people that have mini lathes & milling machines such as Sherline and Tieg.

View attachment Tiny I.C. Notes -- rev B.pdf

View attachment Tiny 1 Frame - rev B.pdf

View attachment Tiny 1A Crank Ret. -- rev B.pdf

View attachment Tiny 2 Gas Tank -- rev B.pdf