You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tiny I.C. Engine

- Thread starter putputman

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

dsquire

Well-Known Member

- Joined

- Mar 18, 2008

- Messages

- 980

- Reaction score

- 15

Gail

That is one nice little running engine. The rain drops are going to have to be pretty quick and have their timing just right if they have any hope of raining on your parade. Thanks for showing it to us all. :bow: :bow:

Cheers

Don

That is one nice little running engine. The rain drops are going to have to be pretty quick and have their timing just right if they have any hope of raining on your parade. Thanks for showing it to us all. :bow: :bow:

Cheers

Don

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Arv, Sam, Kel, Jim, Don, Rudy, Lee, Kevin and Nick.

Thank you all for the kind comments.

Arv, Special thanks to you for publishing the original plans. I hope you don't mind all the liberties I took in changing things to suit my personal preferences.

Kel, I will be doing some carburetor experiments a little later. I appreciate your postings in this area.

Lee, I hope yours runs well as the three that I know of that are running. I have faith that it will.

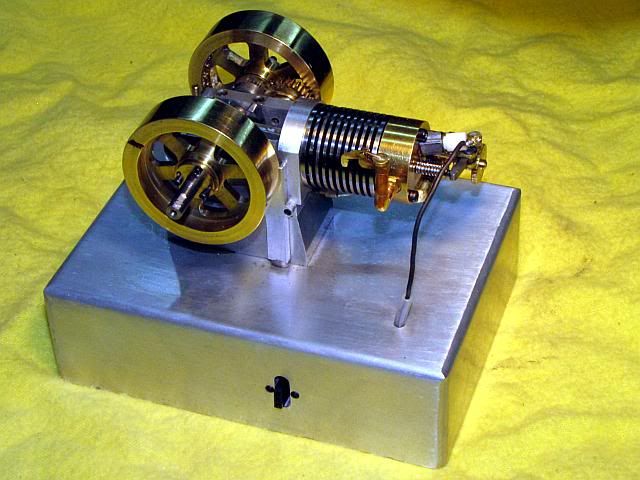

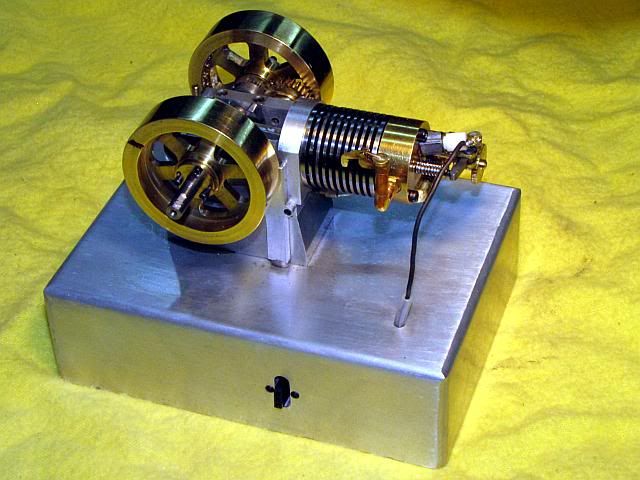

Some of the changes I made are:

1. Most obvious is air cooling vs water cooling.

2. Exhaust comes out from head at the horizontal. This is mostly because I wanted to have a vertical pipe for the exhaust flap and am too lazy to make an angle elbow other than at 90 degrees.

3. Taper lock hubs for the flywheels, just because I like them.

4. Extended fuel filler and vent pipes for easier access.

5. Extended the crankshaft on the back side for power take off and a knurled finger

starting knob.

6. Spoked flywheels.

Glad every one likes the exhaust flap. It's origin can be traced back 60+ years or so to my grandparents farm. One of my fond memories of that era was the jingle of the exhaust flap on the old, even then, Ford tractor at idle. Well, this one doesn't jingle but I can fill the sound in with my mind as I watch it flapping . Not original is the bent over rusty nail used as a hinge pin. They also had a farm engine that did not get used much, but it had a rusty nail hinge pin.

I now have about 5 hours of running time on "Tiny". I have been running on a 100:1 mix of Coleman fuel (Naphtha) and 50:1 two stroke oil. I have pulled the cylinder off and there is trace oil on and around the o-ring so the mix seems adequate. The fuel tank holds just shy of 10cc of fuel. My sustained runs have been at low RPM and a full tank runs about 1 hour 10 minutes. This was at 1500 RPM which is about as low a speed that it runs reliably. RPM was measured with a contact tachometer and there is enough torque at that speed that I can not hear any difference in speed when I take the measurement.

Arv mentioned that his engine heats up quickly. Mine does also. When running at high RPM the carb heats up enough that I get a vapor lock after about 3 to 5 minutes. This may be because I bolted my fuel mixer to the cylinder head and have more heat transfer to it.

The needle valve is very sensitive. I have reworked it to a system similar to that I have used on butane regulators on gauge 1 locomotives, but I have not tried it yet.

I am currently drawing an intake manifold to go between the fuel mixer and cylinder head. I will be placing the fuel mixer horizontal coming out under the exhaust push rod. This is to reduce the heat transfer from the head to the mixer and to allow the mixer to be removed without having to remove the head or removing the engine from the mounting base. That way I can play with fuel mixers or a carburetor easily. Actually I have what I want drawn but now I have to redraw it into something that I can actually make.

Thanks for the interest. I will post photos and more info as things progress.

Gail in NM

Thank you all for the kind comments.

Arv, Special thanks to you for publishing the original plans. I hope you don't mind all the liberties I took in changing things to suit my personal preferences.

Kel, I will be doing some carburetor experiments a little later. I appreciate your postings in this area.

Lee, I hope yours runs well as the three that I know of that are running. I have faith that it will.

Some of the changes I made are:

1. Most obvious is air cooling vs water cooling.

2. Exhaust comes out from head at the horizontal. This is mostly because I wanted to have a vertical pipe for the exhaust flap and am too lazy to make an angle elbow other than at 90 degrees.

3. Taper lock hubs for the flywheels, just because I like them.

4. Extended fuel filler and vent pipes for easier access.

5. Extended the crankshaft on the back side for power take off and a knurled finger

starting knob.

6. Spoked flywheels.

Glad every one likes the exhaust flap. It's origin can be traced back 60+ years or so to my grandparents farm. One of my fond memories of that era was the jingle of the exhaust flap on the old, even then, Ford tractor at idle. Well, this one doesn't jingle but I can fill the sound in with my mind as I watch it flapping . Not original is the bent over rusty nail used as a hinge pin. They also had a farm engine that did not get used much, but it had a rusty nail hinge pin.

I now have about 5 hours of running time on "Tiny". I have been running on a 100:1 mix of Coleman fuel (Naphtha) and 50:1 two stroke oil. I have pulled the cylinder off and there is trace oil on and around the o-ring so the mix seems adequate. The fuel tank holds just shy of 10cc of fuel. My sustained runs have been at low RPM and a full tank runs about 1 hour 10 minutes. This was at 1500 RPM which is about as low a speed that it runs reliably. RPM was measured with a contact tachometer and there is enough torque at that speed that I can not hear any difference in speed when I take the measurement.

Arv mentioned that his engine heats up quickly. Mine does also. When running at high RPM the carb heats up enough that I get a vapor lock after about 3 to 5 minutes. This may be because I bolted my fuel mixer to the cylinder head and have more heat transfer to it.

The needle valve is very sensitive. I have reworked it to a system similar to that I have used on butane regulators on gauge 1 locomotives, but I have not tried it yet.

I am currently drawing an intake manifold to go between the fuel mixer and cylinder head. I will be placing the fuel mixer horizontal coming out under the exhaust push rod. This is to reduce the heat transfer from the head to the mixer and to allow the mixer to be removed without having to remove the head or removing the engine from the mounting base. That way I can play with fuel mixers or a carburetor easily. Actually I have what I want drawn but now I have to redraw it into something that I can actually make.

Thanks for the interest. I will post photos and more info as things progress.

Gail in NM

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

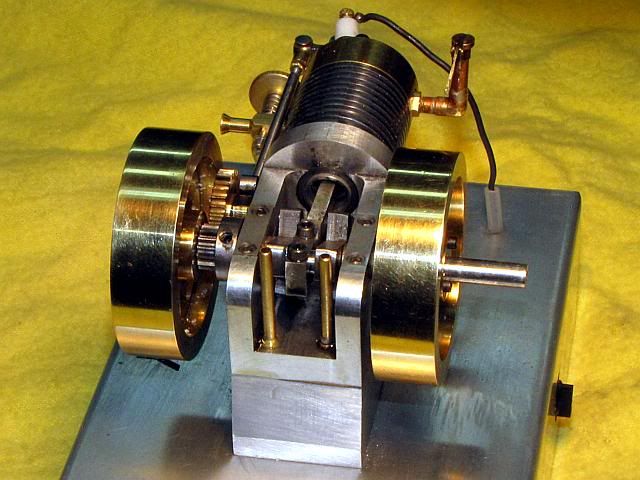

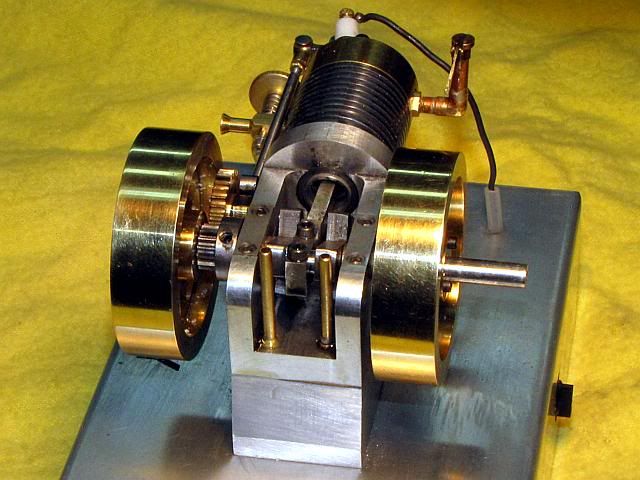

The intake manifold has been built and installed. It is not real neat in that it has two 90 degree bends in it, but at the speed the Tiny runs it should not make a difference. I have enough insulation in it to keep the fuel mixer cool enough that Tiny will run at full RPM with out having any vapor lock problem like I was having. In addition to the extended manifold with cooling fins on it, there are two 0.006 vegetable fiber gaskets in the joints. I also now have a side draft fuel mixer so it is easy to change out when I want to play.

Attached photos probably tell all. 4 machined parts all silver brazed into one assembly with lots of filing work.

Gail in NM

Attached photos probably tell all. 4 machined parts all silver brazed into one assembly with lots of filing work.

Gail in NM

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

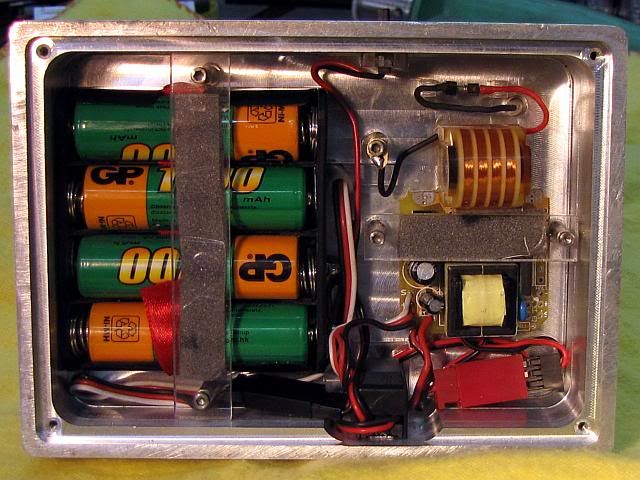

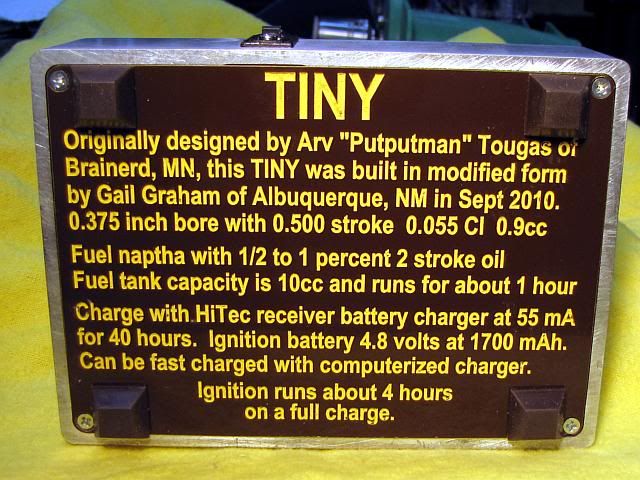

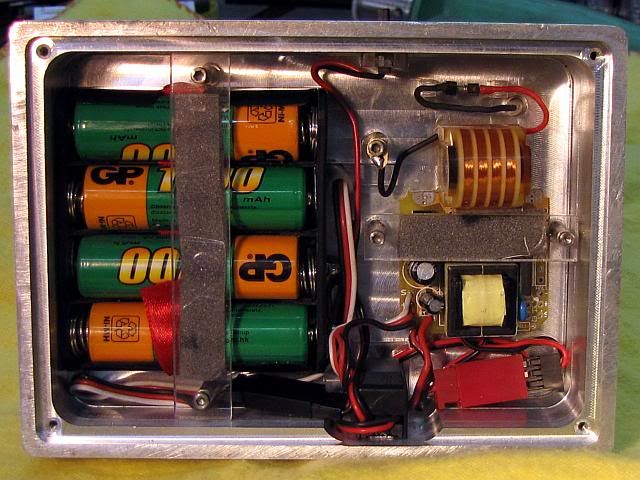

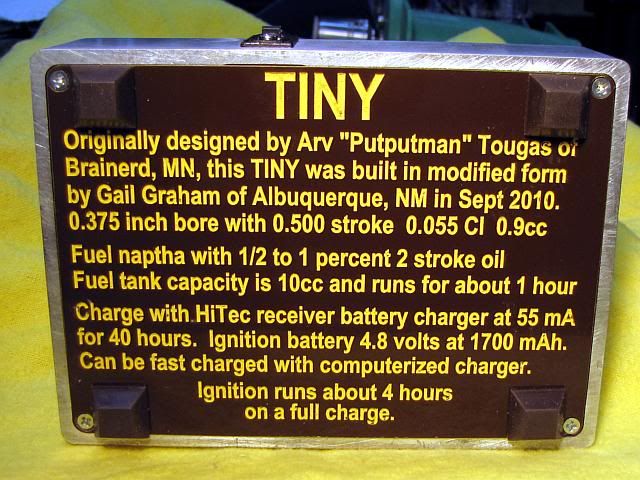

The time has come to put the Tiny project to bed, at least for a while. I still want to build a carb for it, but not right now.

Tiny now has about 11 hours on it. Fuel consumption is about 10cc per hour. Just using the mixture control to adjust RPM the speed range is from about 1300 rpm to 4400 rpm. A few recent changes have been to redo the exhaust flap. It was sticking open part of time so the travel was limited. Compression ratio was reduced from 5.6:1 to 5.0:1 by changing the head gasket. It just seemed like a good idea since naphtha has an octane rating around 50 to 55. The needle valve was changed to a very shallow taper so full rich to lean is about 3/4 turn where it was about 1/16 turn. Larger knob for fuel adjustment.

Everything else is just finishing touches.

And yes, I know I misspelled naphtha on the name plate - and no, I am not going to change it.

Thanks for following along and special thanks to Putputman for the inspiration.

Gail in NM

[ame]http://www.youtube.com/watch?v=mLn7xG8vuPQ[/ame]

Tiny now has about 11 hours on it. Fuel consumption is about 10cc per hour. Just using the mixture control to adjust RPM the speed range is from about 1300 rpm to 4400 rpm. A few recent changes have been to redo the exhaust flap. It was sticking open part of time so the travel was limited. Compression ratio was reduced from 5.6:1 to 5.0:1 by changing the head gasket. It just seemed like a good idea since naphtha has an octane rating around 50 to 55. The needle valve was changed to a very shallow taper so full rich to lean is about 3/4 turn where it was about 1/16 turn. Larger knob for fuel adjustment.

Everything else is just finishing touches.

And yes, I know I misspelled naphtha on the name plate - and no, I am not going to change it.

Thanks for following along and special thanks to Putputman for the inspiration.

Gail in NM

[ame]http://www.youtube.com/watch?v=mLn7xG8vuPQ[/ame]

putputman

Senior Member

- Joined

- Nov 22, 2008

- Messages

- 600

- Reaction score

- 55

I like that Gail. It's especially neat that you didn't have to alter your fuel mixer.

I guess I haven't run mine long enough at one time to get it very hot. I don't know if I would have a vapor locking problem or not.

It looks like the manifold would provide the added space to add a throttle like Kel put on his. I think I will give that a try. The way mine is I wouldn't have enough space to increase the length on the fuel mixer body.

WOW! I was just getting ready to post this note when your latest post popped up with the video & photos. You have really got that running great. I can get about 4300 rpm but can not get down as low as yours. Maybe with a throttle I can.

It is a beautiful engine. You have to be very proud of it.

I guess I haven't run mine long enough at one time to get it very hot. I don't know if I would have a vapor locking problem or not.

It looks like the manifold would provide the added space to add a throttle like Kel put on his. I think I will give that a try. The way mine is I wouldn't have enough space to increase the length on the fuel mixer body.

WOW! I was just getting ready to post this note when your latest post popped up with the video & photos. You have really got that running great. I can get about 4300 rpm but can not get down as low as yours. Maybe with a throttle I can.

It is a beautiful engine. You have to be very proud of it.

Gail;

"And yes, I know I misspelled naphtha on the name plate - and no, I am not going to change it."

I think the errors add character to equipment - and perhaps even humanity. Good on ya...

I like the idea of the info tag on the model - including the operation instructions. I'd say it was clever of you but really I think it was wisdom.....

Beautiful work. I'm not a fan of "small part" machining but between your model and that of PutPutman I may have been convinced to reconsider....at least for one model...thank you.

Cheers Garry

"And yes, I know I misspelled naphtha on the name plate - and no, I am not going to change it."

I think the errors add character to equipment - and perhaps even humanity. Good on ya...

I like the idea of the info tag on the model - including the operation instructions. I'd say it was clever of you but really I think it was wisdom.....

Beautiful work. I'm not a fan of "small part" machining but between your model and that of PutPutman I may have been convinced to reconsider....at least for one model...thank you.

Cheers Garry

Similar threads

- Replies

- 28

- Views

- 4K

- Replies

- 6

- Views

- 945

- Replies

- 25

- Views

- 3K

- Replies

- 413

- Views

- 42K