tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

As some of you might know, the last year I've been poodle-fakin' about with tooling and the like, but I have just succumbed and got to work on an engine I've had in the think tank for quite a while now.

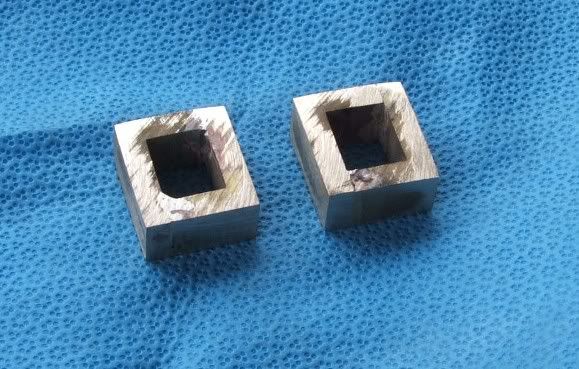

Don't want to let too many cats outta the bag this early, but here's some progress - the components for the cylinders - hope to get 'em silver soldered up in the morning.

Don't want to let too many cats outta the bag this early, but here's some progress - the components for the cylinders - hope to get 'em silver soldered up in the morning.