Its been a while since I updated this thread so here goes.

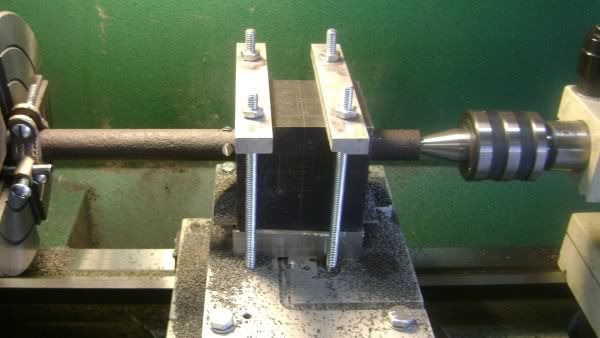

I made a plate to go on my cross slide to use it as a boring table to bore out the cyls.

Made a boring bar out of some rusty bar and put it between centers to do the boring. Used a set screw to adjust the cutting tool and another to lock it in place.

I used a auto brake wheel cyl hone to hone the cyls. For got to take any pics of that.

I used the off cuts of the steam cyls to make the end caps (?) for the cyls.

I cut off as much as I could on my 4 x 6 saw to make it as round as possible be for turning them in the lathe

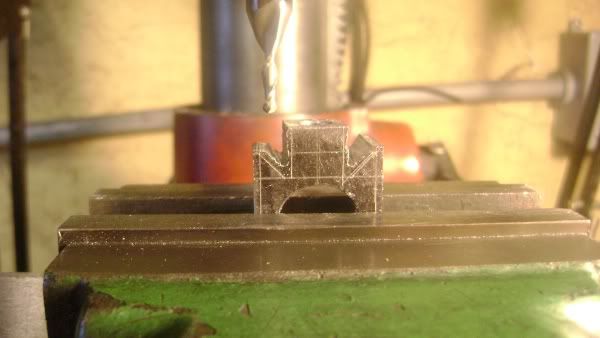

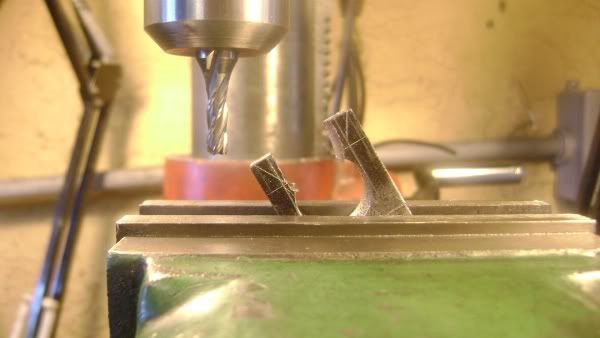

For the steam chests I chain drilled around the inside of the blocks for the chests and cut out the center with a hacksaw,then milled the insides. I them made the valves and the vale nuts. The valves are cast iron and the nuts a re bronze. The cyls and the steam chest are sat iron as well as the end caps/ cyl heads.

The valve rods are stainless steel.

I did some profiling on the cyls to make them more like castings ala kvom.

I also took his idea of putiing 2 countersunk cap screws in th steam chest to keep them in place when the top cover is taken off.

I'm going to mill a .020 depression in the covers inside of the gasket area and may do the same for the top of the covers.

That brings it up to date as of today. I will profile the other cyl tomorrow.

The bolts in the steam chests are temporary, proper scale hex head bolts will be put in for the final assembly.

Ron