Hi all, I got a little more done on my loco build.

Made the axles and axle boxes. The axle boxes are cast iron and the axles are made from a long bolt made by Caterpillar Machinery. Don't know what it was for but it sure turned nice on the lathe with a very nice finish.

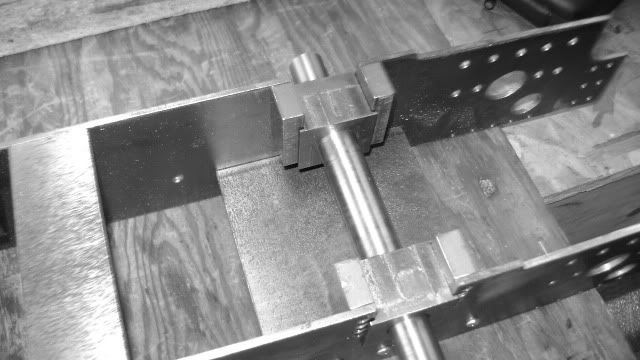

I squared up stock for the axle boxes long enough to make 2 aout of 1 piece so that the hole would be concentric in both the left and right boxes. I drilled to 11/16 then bored to size.

I then marked out the boxes and cut in half.

Put them in the mill and trued up the saw cut ends and brought to size. Then marked out for and milled the grooves to slide on the horn plates.

Then a lot of filing to get the boxes to fit well.

Now a question, I know that the distance between the axles have to be really close as far as the distance between ,say, the leading axle and the drive axle. How big a variance is to much between,lets say, the distance from the leading axle to the drive axle on the right side as compared to the left side?

I hope I'm not confusing you with my description.

Thanks for looking in.

Ron