Thanks, Jason.

nibbled away at the bits through the week, and have got them done.

Set up the parts again on the mill to do the decorative relief on the sides, luckily, I had a washer that shimmed up the part to the right height without having to do anything else

Then into the vice to drill and tap the hole for the adjusting screw, and milling the slot for the cam roller

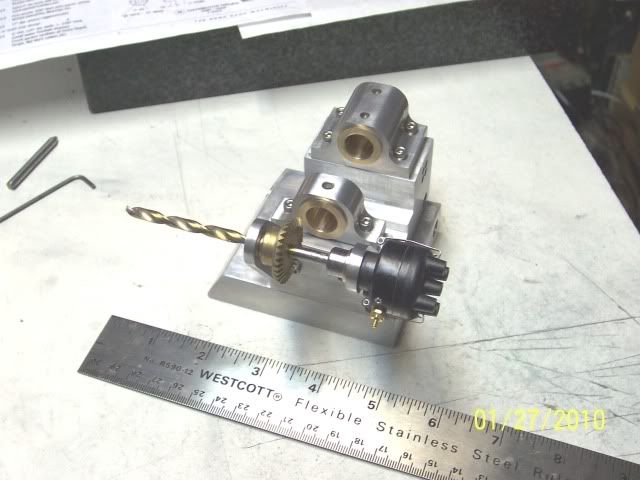

Turned, drilled, and parted off the rollers, and parted off some drill rod for the pins, and here's all the parts

Stick'em together:

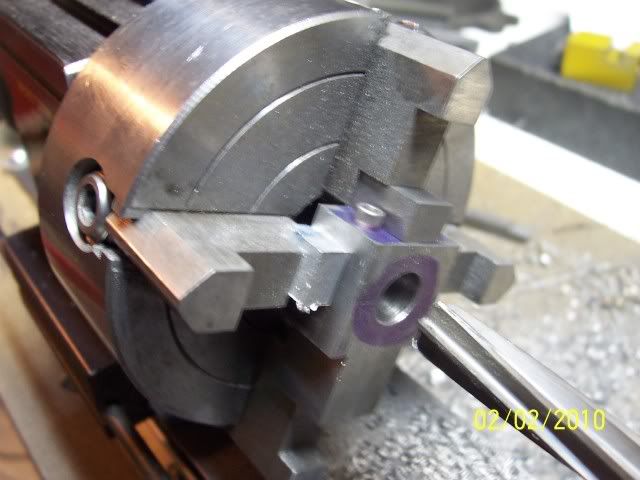

And here they are where they belong

Starting to look like an engine!

Cheers, Joe

nibbled away at the bits through the week, and have got them done.

Set up the parts again on the mill to do the decorative relief on the sides, luckily, I had a washer that shimmed up the part to the right height without having to do anything else

Then into the vice to drill and tap the hole for the adjusting screw, and milling the slot for the cam roller

Turned, drilled, and parted off the rollers, and parted off some drill rod for the pins, and here's all the parts

Stick'em together:

And here they are where they belong

Starting to look like an engine!

Cheers, Joe