You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small V8

- Thread starter stevehuckss396

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Lakc

Well-Known Member

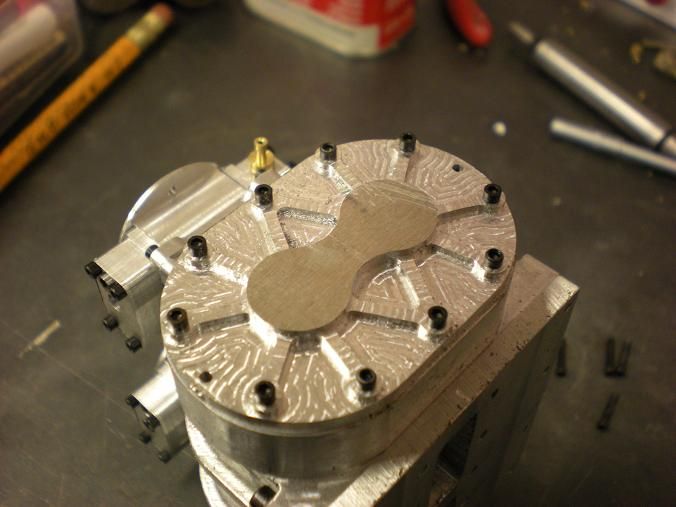

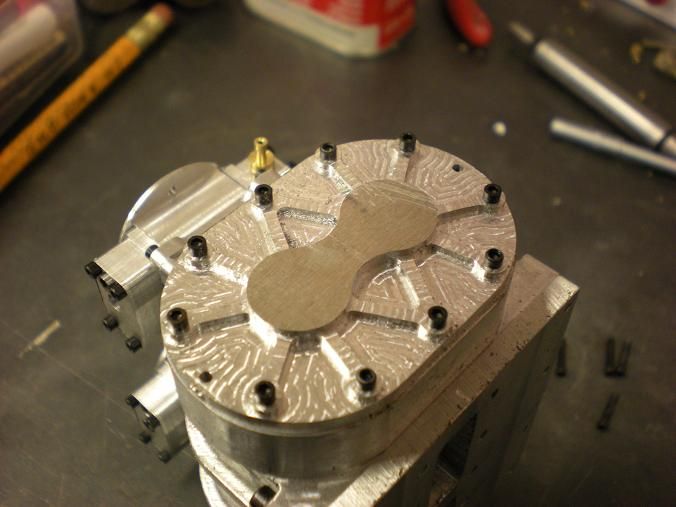

Are those 2-56 or 4-40 threaded holes for the end caps? How did you keep the bores straight? Last time I tried overlapping holes they wanted to move towards each other.

Lakc said:Are those 2-56 or 4-40 threaded holes for the end caps? How did you keep the bores straight? Last time I tried overlapping holes they wanted to move towards each other.

The screws in the base are #2-56. The end caps are #0-80's

I bored it on the mill using a boring head and a very stout boring bar.

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

I think I have one i can borrow. I am not ready for rotors yet but when I am, I'll figure out something!!

G'day Steve, my dry sense of humor is coming out, I was only having a lend of you,

Please don't be offended, according to Google maps Detroit Michigan is 25,422 km from my location and approx 55 days driving via the North Pacific ocean, Don't know about driving across that but.

Cheers Baz.

G'day Steve, my dry sense of humor is coming out, I was only having a lend of you,

Please don't be offended, according to Google maps Detroit Michigan is 25,422 km from my location and approx 55 days driving via the North Pacific ocean, Don't know about driving across that but.

Cheers Baz.

rcfreak177 said:G'day Steve, my dry sense of humor is coming out, I was only having a lend of you,

Please don't be offended, according to Google maps Detroit Michigan is 25,422 km from my location and approx 55 days driving via the North Pacific ocean, Don't know about driving across that but.

Sounds good! I'll see you in 55 days then.

- Joined

- Jul 3, 2010

- Messages

- 278

- Reaction score

- 10

Hi Steve,

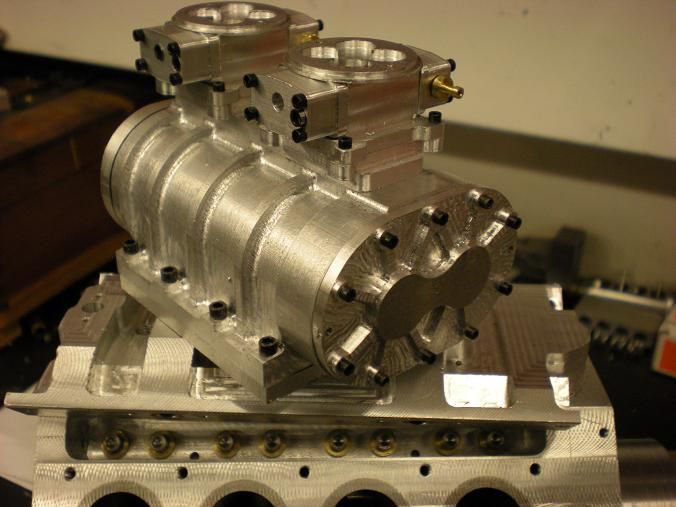

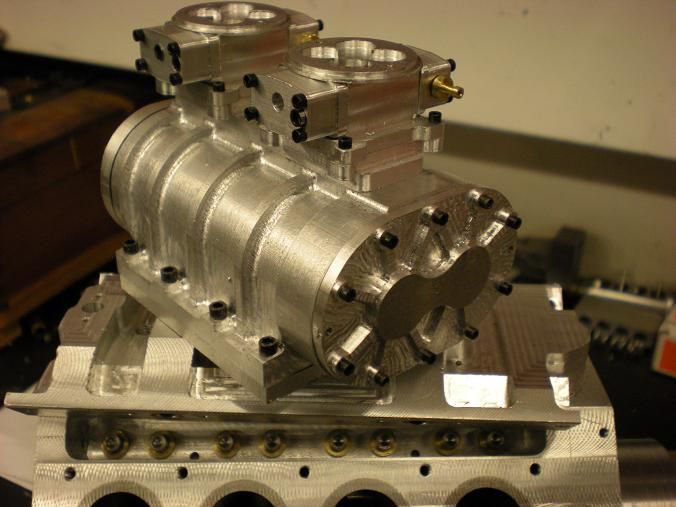

Compliments for your build, its a pleasure to follow along. Very nice job done with the 3D milling on the blower housing, its clear that you have the CNC materiel in your fingers and perfectly under control! :bow: :bow:

Regards Jeroen

Compliments for your build, its a pleasure to follow along. Very nice job done with the 3D milling on the blower housing, its clear that you have the CNC materiel in your fingers and perfectly under control! :bow: :bow:

Regards Jeroen

coopertje said:Very nice job done with the 3D milling on the blower housing

I just learned how to do 3D toolpaths. The guys at the CamBam forum talked me thru it and gave some tips. I'm happy with it but the next one will be better. It's easier than you think.

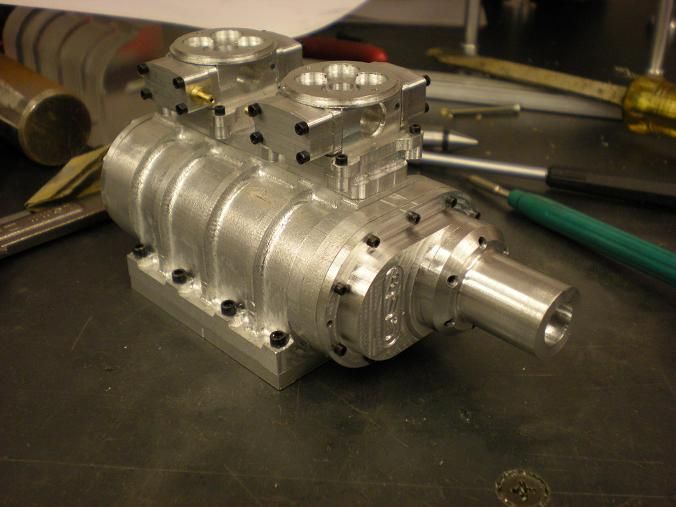

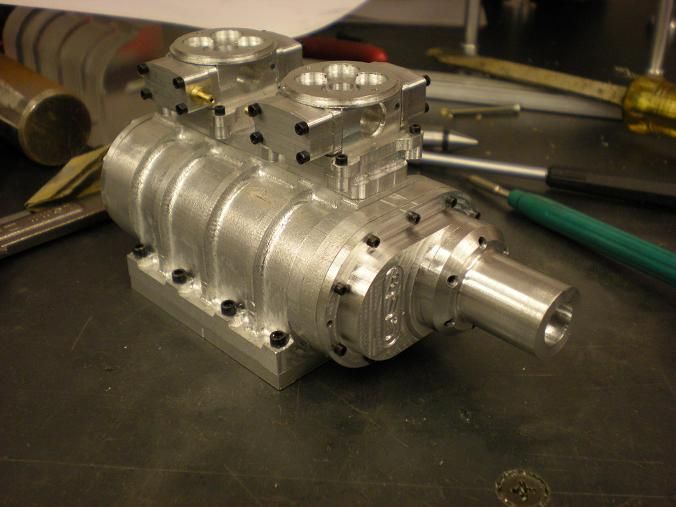

Made a few more pieces.

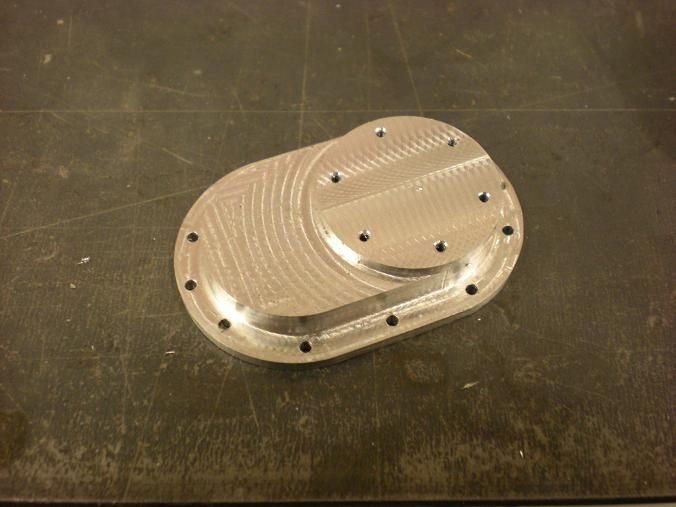

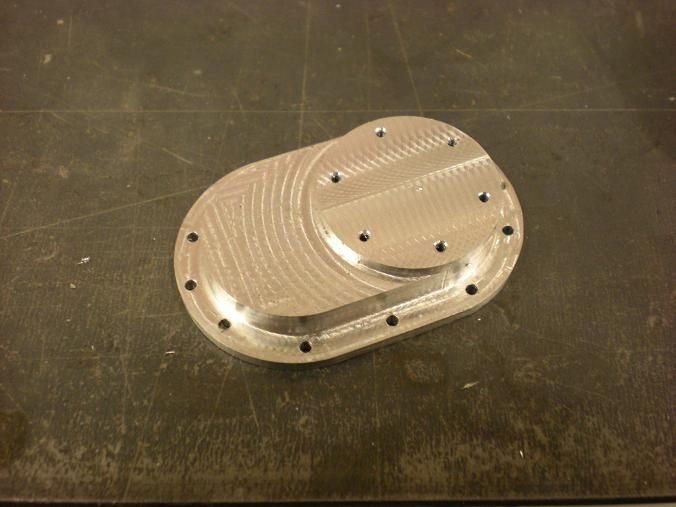

Made the rear cover, front cover, and the gear case for the blower.

Made the rear cover, front cover, and the gear case for the blower.

- Joined

- Jul 16, 2007

- Messages

- 2,993

- Reaction score

- 1,061

Aw c'mon Steve, you're breaking my heart. I really don't want to have to build a supercharger for any of my engines! I know it's been said by others and me but this is first rate stuff.

On a full sized supercharger they use helical gears to keep everything tight. Being that they are labor intensive to make you might consider this option. When I did a lot of motorcycle repair I found the cam gears on a Yamaha had split teeth, about 2:1. The narrow part of the gear was loaded again the wide part of the gear with some compression springs fixed radially between the two. Once pressed into the mating gear this would virtually eliminate and lash between the teeth. Have you figured out how you're going to gear yours?

George

On a full sized supercharger they use helical gears to keep everything tight. Being that they are labor intensive to make you might consider this option. When I did a lot of motorcycle repair I found the cam gears on a Yamaha had split teeth, about 2:1. The narrow part of the gear was loaded again the wide part of the gear with some compression springs fixed radially between the two. Once pressed into the mating gear this would virtually eliminate and lash between the teeth. Have you figured out how you're going to gear yours?

George

gbritnell said:Have you figured out how you're going to gear yours?

George

I'm going to use spur gears. 64 pitch with lots of teeth. I doubt the blower will see much in the way of a load. My Chevy never made any boost until the throttle was wide open.

Lakc

Well-Known Member

More teeth on the crank pulleystevehuckss396 said:I'm going to use spur gears. 64 pitch with lots of teeth. I doubt the blower will see much in the way of a load. My Chevy never made any boost until the throttle was wide open.

Lakc said:More teeth on the crank pulley

I think G was talking about gearing the rotors together. The drive will be a .080 pitch belt. 40 tooth crank, 32 tooth blower just like my Chevy.

Lakc

Well-Known Member

Yes he was  I was talking about your lack of low rpm boost

I was talking about your lack of low rpm boost

The spring loaded gears George was talking about, I have not seen used on a camshaft before. They are real common on instruments and backlash sensitive things, like ham radio variable capacitor drives, and often used in automotive for stopping things like neutral gear rattle in manual transmissions. If the spring tension was greater then the side force on the lash adjuster from the valve spring, it would work like anti backlash, otherwise, I suspect, it is mostly for noise control.

The spring loaded gears George was talking about, I have not seen used on a camshaft before. They are real common on instruments and backlash sensitive things, like ham radio variable capacitor drives, and often used in automotive for stopping things like neutral gear rattle in manual transmissions. If the spring tension was greater then the side force on the lash adjuster from the valve spring, it would work like anti backlash, otherwise, I suspect, it is mostly for noise control.

Lakc said:I was talking about your lack of low rpm boost

Didn't lack boost at low RPM. Lacked boost when the throttle was closed. Made good boost for a street car @ 10.5 Lbs. Torque curve looked like a box. Over 900FtLbs from 2500 - 7200 Rpm. I suspect it was making boost at low RPM. Hahahhaa!!!

I don't see myself holding the throttle wide open on the model engine so the rotors should see minimum loading. It's mostly for looks but it would be cool if I can get it to whine, love the sound of a roots!!

Lakc

Well-Known Member

10.5/14.7=.714 equals a 70% larger engine, not shabby at all.  There are scaling factors that work against model sized compressors, although I cannot remember all the specifics at the moment. I seem to recall the Hodgson radial, although fairly large itself, the compressor section merely acts as a diffuser, not providing any excess manifold pressure above ambient. Ill put that on my list to talk to Lee about it at names, along with that tailstock for the Sherline rotary table I wanted... Now its bedtime, hopefully we dont have another icy drive to work in the AM.

There are scaling factors that work against model sized compressors, although I cannot remember all the specifics at the moment. I seem to recall the Hodgson radial, although fairly large itself, the compressor section merely acts as a diffuser, not providing any excess manifold pressure above ambient. Ill put that on my list to talk to Lee about it at names, along with that tailstock for the Sherline rotary table I wanted... Now its bedtime, hopefully we dont have another icy drive to work in the AM.

Steve, that looks great. Maybe I missed it, but how did you make the bores for the rotors? Boring head, or lathe? I hope to make it to NAMES this year to see it.

Aerodynamic compressors have problems with scale. Positive displacement types, including Roots, scale well except that gaps and clearances are impossible to scale.

Aerodynamic compressors have problems with scale. Positive displacement types, including Roots, scale well except that gaps and clearances are impossible to scale.

dieselpilot said:Maybe I missed it, but how did you make the bores for the rotors? Boring head, or lathe?

Positive displacement types, including Roots, scale well except that gaps and clearances are impossible to scale.

Was bored on the mill with a boring head.

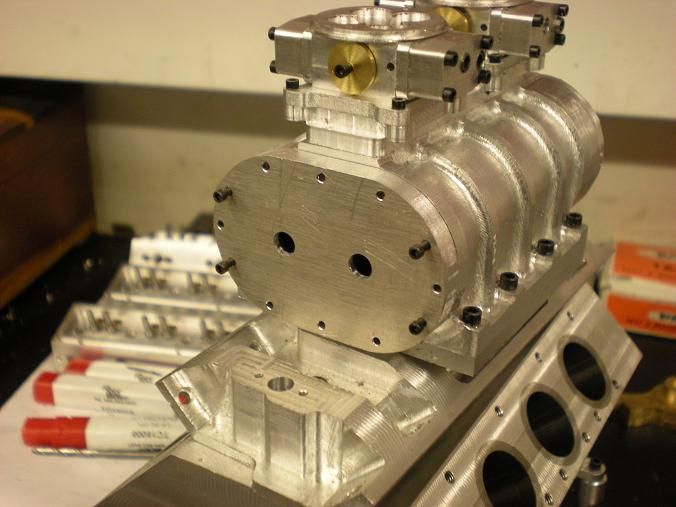

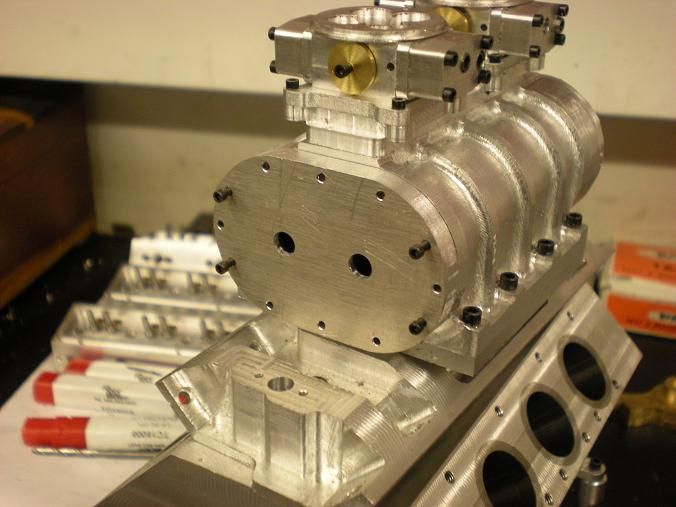

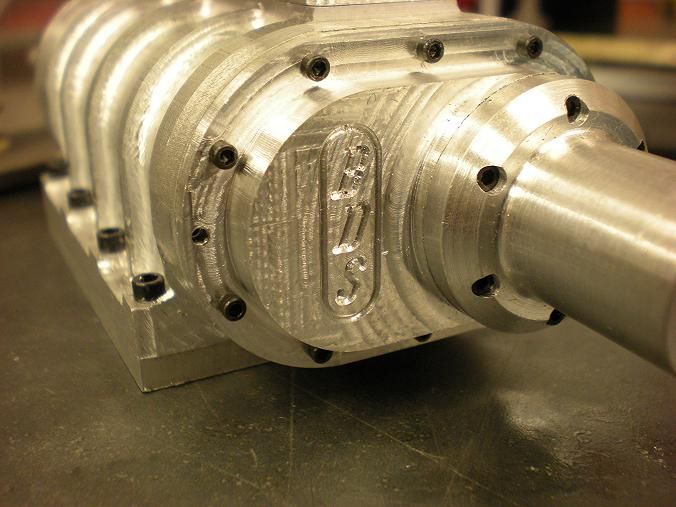

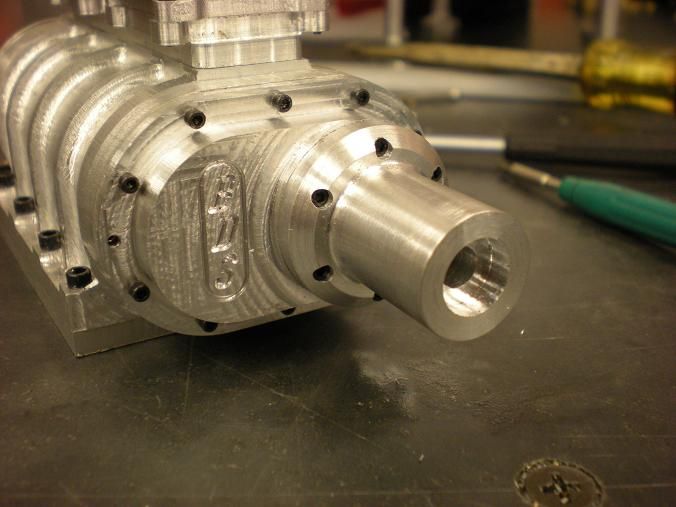

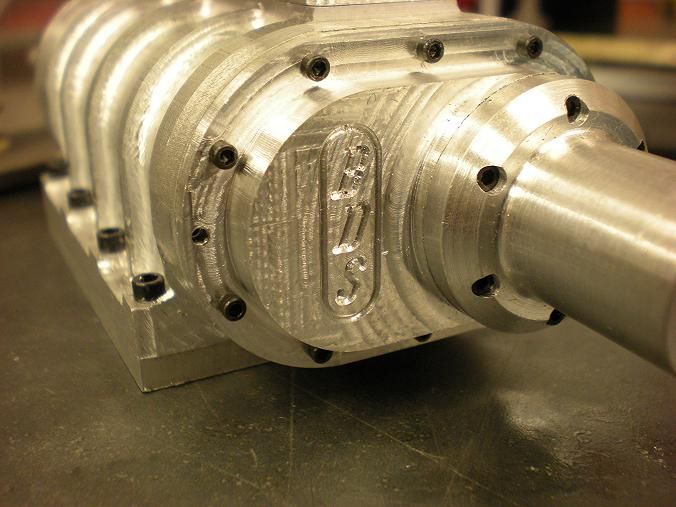

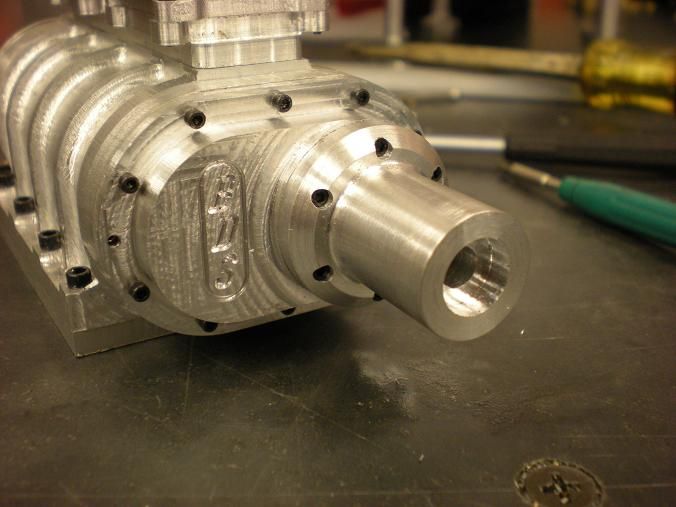

I spent today putting the final touches on the covers. I have all the gear pockets and bearing pockets cut into the rear cover and gear case. Then I had the idea to make the case look like the one I used to have so i engraved BDS in the gear case. Blower Drive Service builds some of the finest blowers available.

Then I made the drive snout.

I'm taking tomorrow off!!

Then I made the drive snout.

I'm taking tomorrow off!!

stevehuckss396 said:Was bored on the mill with a boring head.

Well I'm glad you weren't bored will you were boring with the boring head....

da do tish! Thankyou I'm here all week....try the meatloaf.

Like the blower Steve!

Dave

Similar threads

- Replies

- 413

- Views

- 42K

Latest posts

-

-

Another Knucklehead, built via castings, as a Draw-Tech design, upscaled

- Latest: The Ignoble Troll

-

-

-

-

-

-

-

-