The pump will pull water from the bottom of the radiator and push it into the odd bank of cylinders. It will cross in the back thru the bellhousing adapter and come back thru the even bank of cylinders. Then water will be forced up thru the head, into the manifold, and out the water neck and back into the radiator.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small V8

- Thread starter stevehuckss396

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Not much to report. I made a test rod to check my rod length. The rods are 1.350 C to C so I made a piece with the 2 holes at 1.350. Then the piece was milled to at least 1/2 way thru the holes and cleared to miss the cylinder walls. The rod was set on the crankshaft and a wrist pin was inserted into a piston. The piston was then set into the cylinder and the piston brought to top dead center.

Cyl #1 +.009 ( piston out of the bore .009)

Cyl #7 +.007

Cyl #2 +.012

Cyl #8 +.010

So with this data I can see that my decks from front to back are less than .003 out and the difference between the 2 decks are .003 out. I'll take that any day.I am going to make my rods 1.340 and if the #2 piston sticks out .002, no harm done.

Maybe this week will be spent making rods and bearings.

jpeter said:Lookn' good. What compression ratio you shooting for? Gonna have it running by NAMES?

5.5:1 and NO!

Alexandre Machado said:To use gasoline, the ratio would be higher, right?

5.5:1 is plenty good for gas. I have a 1928 Model "A" in the garage with 4.22:1 and it runs just fine.

Lakc

Well-Known Member

Thats certainly very close and tight tolerances, but dont rule out the crankpins being a little off. Thats traditionally (full size) where the largest part of the compression ratio variance comes from. Even full size, them crankshafts are hard.stevehuckss396 said:So with this data I can see that my decks from front to back are less than .003 out and the difference between the 2 decks are .003 out. I'll take that any day.I am going to make my rods 1.340 and if the #2 piston sticks out .002, no harm done.

You can make each rod a custom length fit to each cylinder on those "absolutely positively gotta have every last horsepower" type of motors as well. But here I am giving away my drag racing secrets.

Lakc said:rule out the crankpins being a little off.

That's why I check with a test rod. This way the actual length from the crankshaft to the deck is factored in. .003 won't affect much of anything. Peewee was .015 from the shortest to the longest so I split the differance and no way can anybody tell. I'll take .003 any day!!

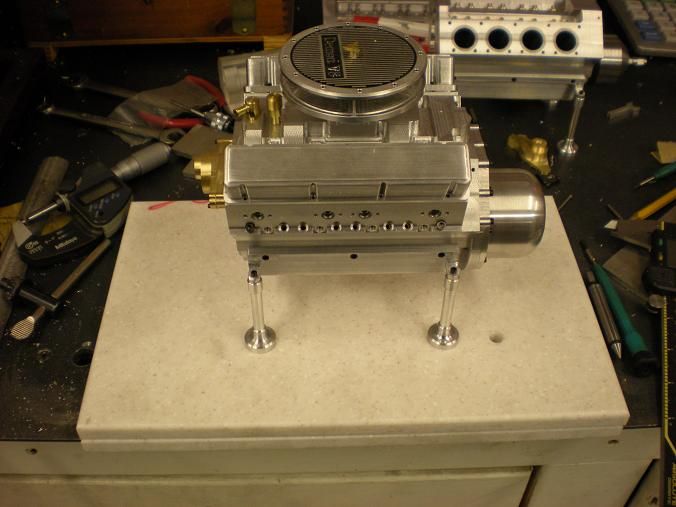

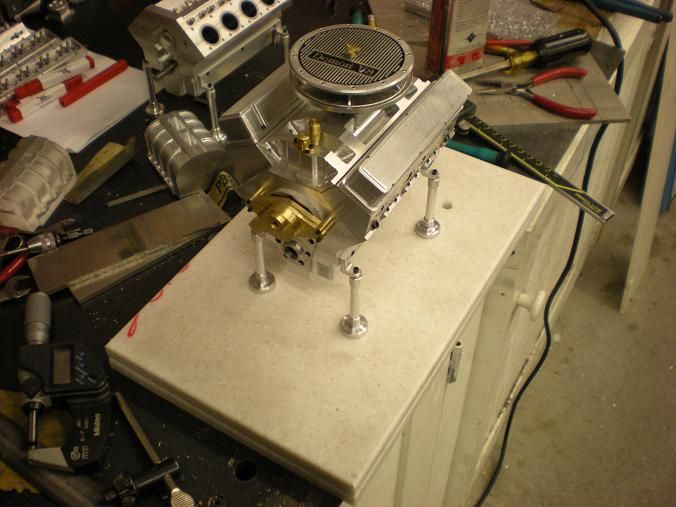

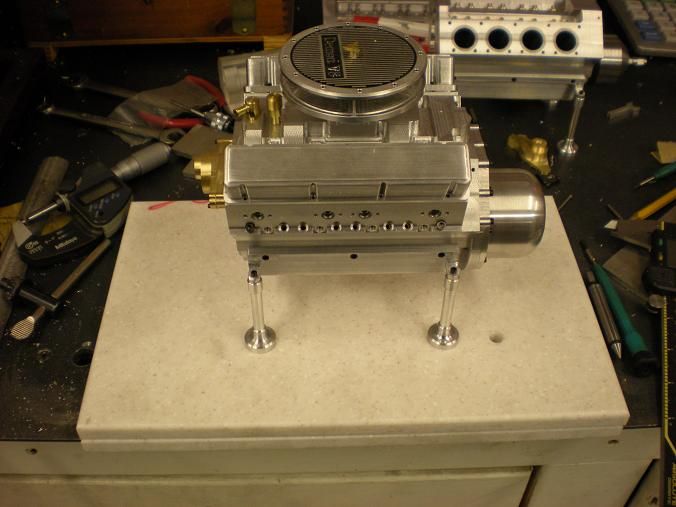

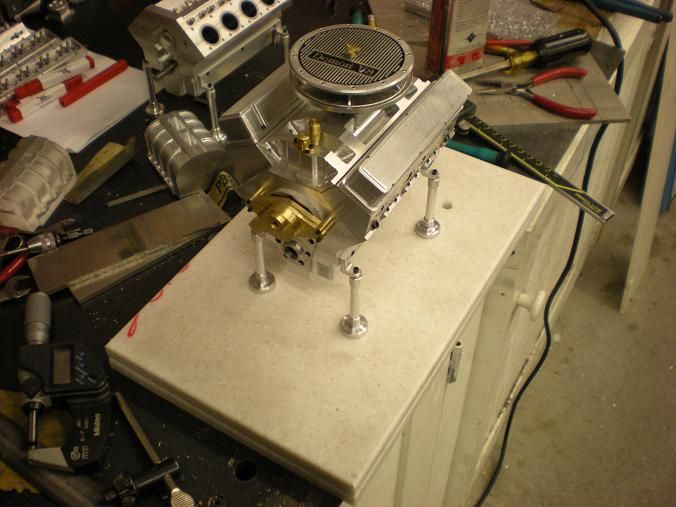

Still trying to get over this cold so I figured, work on something easy. My friend went to the local cabinet shop and asked about some corian counter top material. When the guy found out what it was for he gave up a piece that was cut out to install the sink. This piece was plenty big enough for me to get 2 pieces 7-1/2 X 12 for the display bases. After drilling the holes that will mount the engine, gas tank, and radiator, I used a corner rounding bit to ease the top corners. The big holes are threaded and will allow me to secure the 2 pipe stands that will pass the sensor wire and coil wire from the ignition.

I like this stuff for 2 reasons. First it resists gas and oil very well, and second, because it looks like a miniature terrazzo floor.

I like this stuff for 2 reasons. First it resists gas and oil very well, and second, because it looks like a miniature terrazzo floor.

Lakc

Well-Known Member

Looking good! ;D

gbritnell said:Outstanding Steve!!!!!

gbritnell

Thanks Lakc & George! After all this, hope it runs. I'm getting that nervous feeling that you get when you make it past the half way point!!

trumpy81

Member

- Joined

- Oct 31, 2010

- Messages

- 219

- Reaction score

- 52

GDay All,

Steve, what an excellent job you have done! :bow: :bow: :bow:

I am totally jealous at this point because I designed a very similar engine in Autodesk Inventor so time ago that I am planning to build.

Your bore and stroke dimensions are close to mine as well .... bah humbug!

I wish you well with the project and I have read all from the first post to this. It has been a very interesting journey so far and I'm just as eager as everyone else to see the completed engine up and running. I don't think you will have too many problems getting it running, if the quality of your work is any indication.

It is also encouraging to know that my own design is feasible and machinable even though I'm still collecting tooling and materials, not to mention skills, I figure, if you can do it so can I .... maybe .... lol

If you end up offering plans for this engine, please put my name on the list :big:

Looking forward to the next chapter, keep 'em coming! :big:

Thanks for sharing!

Steve, what an excellent job you have done! :bow: :bow: :bow:

I am totally jealous at this point because I designed a very similar engine in Autodesk Inventor so time ago that I am planning to build.

Your bore and stroke dimensions are close to mine as well .... bah humbug!

I wish you well with the project and I have read all from the first post to this. It has been a very interesting journey so far and I'm just as eager as everyone else to see the completed engine up and running. I don't think you will have too many problems getting it running, if the quality of your work is any indication.

It is also encouraging to know that my own design is feasible and machinable even though I'm still collecting tooling and materials, not to mention skills, I figure, if you can do it so can I .... maybe .... lol

If you end up offering plans for this engine, please put my name on the list :big:

Looking forward to the next chapter, keep 'em coming! :big:

Thanks for sharing!

trumpy81 said:I am totally jealous at this point because I designed a very similar engine in Autodesk Inventor so time ago that I am planning to build. Your bore and stroke dimensions are close to mine as well .

It is also encouraging to know that my own design is feasible and machinable even though I'm still collecting tooling and materials, not to mention skills, I figure, if you can do it so can I .... maybe .... lol

I would like to see some of your models someday to see how other people think. I have another club member who has a V8 of this size running. Jim Peters "Victory V8" is almost exactly the same dimensions. It's great to see how he did some things and find myself wishing I did mine that way. Some things I like my way better. I think looking at others methods can make my future designs better. I don't mind sharing my methods if they will help make things better for someone else.

Cheers!!

Thanks for the kind words. I'm finding tough though to work with the engine setting around the shop cuz all I do is play with it. I'm gonna have to move it to the basement or somewhere so I can get some other stuff done. I intended this post to be longer but I'm breaking it off early so I can start the v8...again.

Lakc

Well-Known Member

Thats what were all here for, hopefully to give as well as take!stevehuckss396 said:I think looking at others methods can make my future designs better. I don't mind sharing my methods if they will help make things better for someone else.

I found out your club meetings are the same night as my radio club, which puts me at hazel park elementary school. What time do your meetings usually wrap up?

Lakc said:What time do your meetings usually wrap up?

Meetings start at 7:00PM which means 7:15 and run to 8:30ish and then we gab a little and I usually get out about 10:30 - 11:00PM. Unless it runs late.

Lakc

Well-Known Member

Sounds good, will definately have to do some planning, and hope google maps doesnt re-order the lettering on the campus.  I was afraid if I showed up and had to ask, nobody would know what the S building was.

I was afraid if I showed up and had to ask, nobody would know what the S building was.

Similar threads

- Replies

- 413

- Views

- 42K