You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small V8

- Thread starter stevehuckss396

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

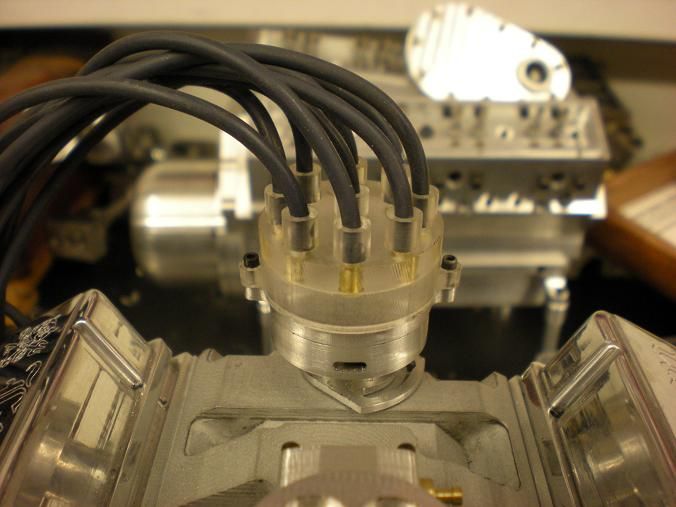

Thanks for the vote of confidence. No pics yet but I started the distributor.

Thanks for the positive comments and no chance of a Wednesday run.

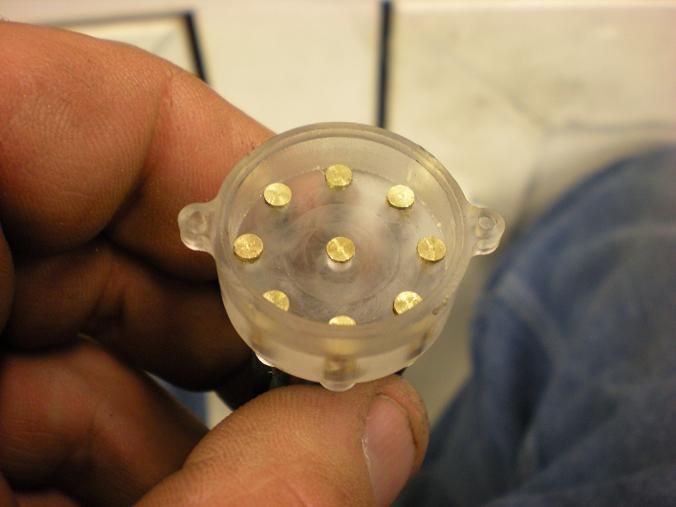

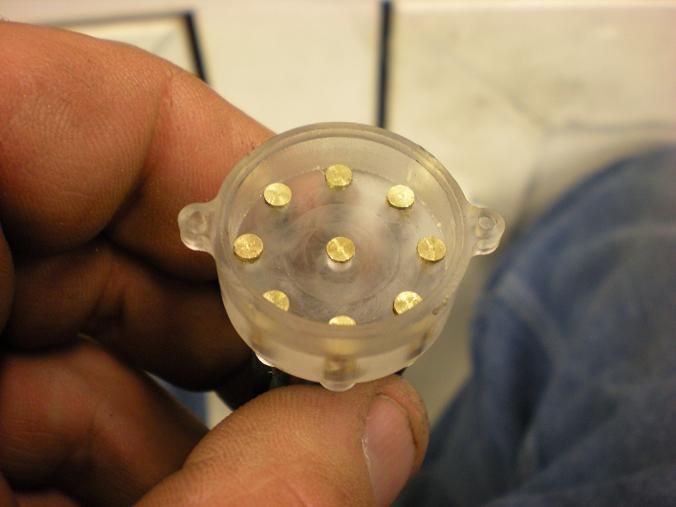

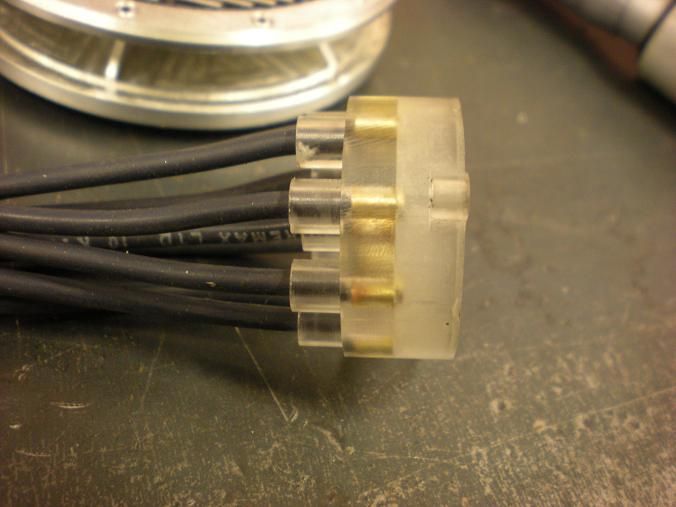

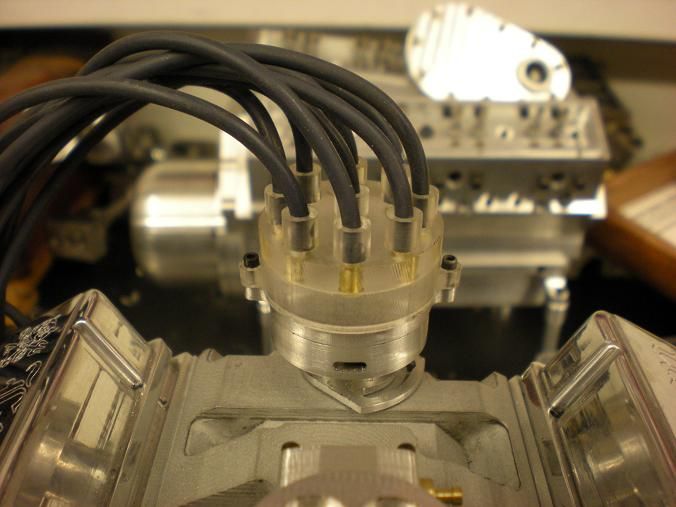

Continuing along with the distributor the electrodes were made for the cap. They are a simple turned piece with a small hole drilled about 3/4 of the way thru.

The hole gets filled with solder about 3/4 of the way up.

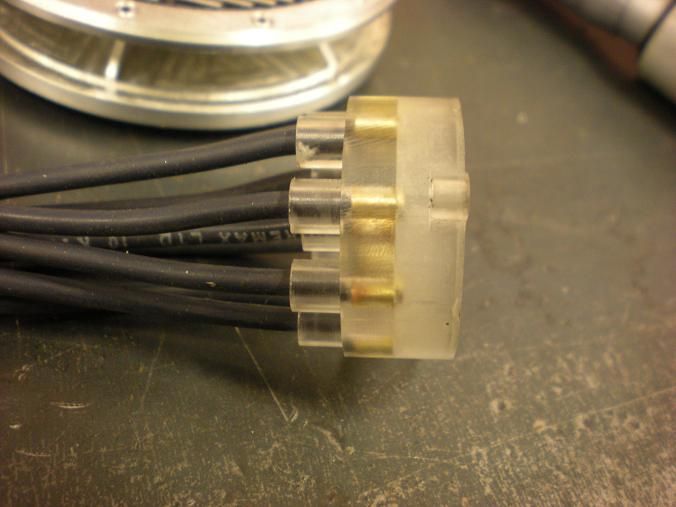

I used the 10,000 volt wire that S/S sells. The wire measured about .108 so the cap got drilled .110 and the brass is .112 inches. The end got skinned about .125 long.

The solder gets heated to molten and then the wire gets stuffed into the hole.

The electrodes were made .002 larger than the hole in the cap. The wire gets threaded thru from the bottom and the brass is pressed into the cap.

Continuing along with the distributor the electrodes were made for the cap. They are a simple turned piece with a small hole drilled about 3/4 of the way thru.

The hole gets filled with solder about 3/4 of the way up.

I used the 10,000 volt wire that S/S sells. The wire measured about .108 so the cap got drilled .110 and the brass is .112 inches. The end got skinned about .125 long.

The solder gets heated to molten and then the wire gets stuffed into the hole.

The electrodes were made .002 larger than the hole in the cap. The wire gets threaded thru from the bottom and the brass is pressed into the cap.

kcmillin said:I really like your method with the spark plug wires. :bow: Very Clean and neat looking. What are you using for the plug end?

Kel

I can best describe it as a cap with the wire soldered on the top. The inside of the cap will be .005 larger than the tip of the spark plug. I would like to find something to use as a boot but I might Have to make something.

- Joined

- Jan 19, 2010

- Messages

- 1,193

- Reaction score

- 41

stevehuckss396 said:I would like to find something to use as a boot but I might Have to make something.

I am using R/C fuel tubing with heat shrink tubing over that on my TI4. It makes a nice looking boot, however the boot ends up much larger than the wire, due to the thick walled tubing, but it does hold nice and tight to the 1/8" brass plug contact.

Is the cap you are talking about made of brass? Perhaps you could use only heat shrink tubing, but what type of friction device are you using to hold the wire to the plug?

Kel

kcmillin said:I am using R/C fuel tubing with heat shrink tubing over that on my TI4. It makes a nice looking boot, however the boot ends up much larger than the wire, due to the thick walled tubing, but it does hold nice and tight to the 1/8" brass plug contact.

Is the cap you are talking about made of brass? Perhaps you could use only heat shrink tubing, but what type of friction device are you using to hold the wire to the plug?

Kel

The cap will be brass and the boot will need to be silicon rubber. The boot needs to be a 90 degree boot. The insulator is .125 and the brass plug contact is .080.

aermotor8 said:steve, bob shores used to make spark plug boots. i think he used a liquid rubber of some kind and he poured it in to a split mold.

just a thought, some one else might know what all is involved in this procedure.

as always you produce some very amazing work :bow: , i like following along.

chuck

I have already drawn a few molds in cad. Working on it.

jpeter said:Regarding the boot mold, geeze and just when I think I've got a unique idea.

Thats the easy part. Finding the right stuff to pour into it is the hard part. One fellow at the meeting said he had enough to make all the boots we need for our engines. PINK! I don't know about you but I non't want pink boots.

Rick fell again at work and may have rebroke his thumb and possibly the screws they put in last month.

I was lazy today. Didn't do much but I did make the balance of the spark plugs with 2 extra.

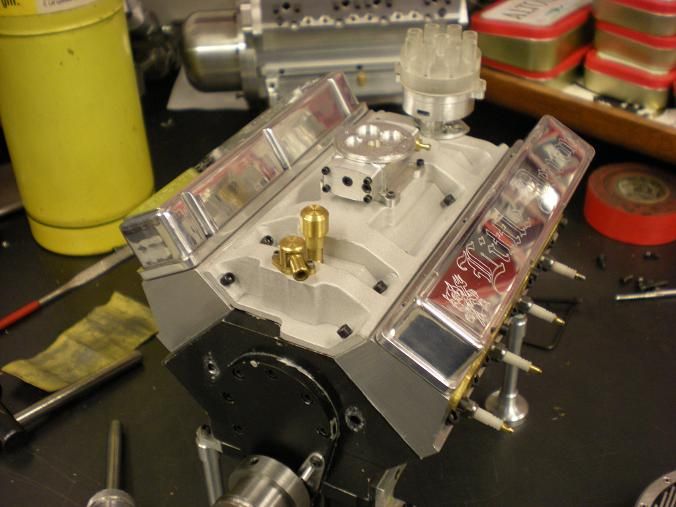

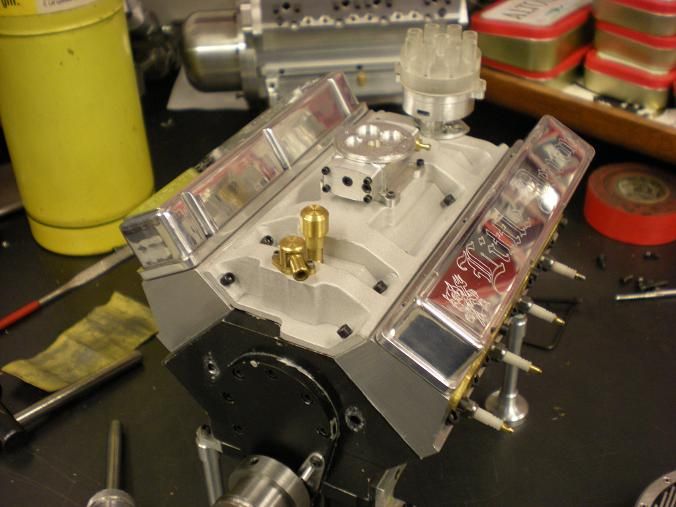

I went up and got a Dremel tool and ground what sharp edges I could get to on my intake. The piece was then sand blasted. I kind of like the way it looks. I think I'm going to clear coat it and leave it alone instead of paint.

I went up and got a Dremel tool and ground what sharp edges I could get to on my intake. The piece was then sand blasted. I kind of like the way it looks. I think I'm going to clear coat it and leave it alone instead of paint.

Lakc

Well-Known Member

The proper diaelectric material can never be an affront to ones manliness. ;Dstevehuckss396 said:Thats the easy part. Finding the right stuff to pour into it is the hard part. One fellow at the meeting said he had enough to make all the boots we need for our engines. PINK! I don't know about you but I non't want pink boots.

The trouble with most black things is if they used carbon for the color, thats a big no-no with ignition systems. I think good old Mopar black RTV would work, however.

Lakc said:I think good old Mopar black RTV would work.

Jim tried it. Wouldn't set up in the mold. Every spark boot i have ever owned was black. Something black has gotta work

dsquire

Well-Known Member

- Joined

- Mar 18, 2008

- Messages

- 980

- Reaction score

- 15

stevehuckss396 said:Jim tried it. Wouldn't set up in the mold. Every spark boot i have ever owned was black. Something black has gotta work

Steve

Here is a link to a couple of places that might be able to help. I have only read about them and not used them but they sound good.

http://www.freemansupply.com/

http://www.miapoxy.com/

Check them out and hopefully you can find something other than pink for those boots. Otherwise those engines are looking fantastic, keep up the good work.

Cheers

Don

Lakc

Well-Known Member

The 8 year old tubes in my toolbox probably wont, but if you allow some air to reach different parts of the mold with stringers, it should. One major problem with any RTV is its crappy short shelf life.stevehuckss396 said:Jim tried it. Wouldn't set up in the mold. Every spark boot i have ever owned was black. Something black has gotta work

There is a plastics place on 8 mile that supplies granular rubber for plastic injection molds. That requires some tight temp controls, and a piston to pressurize the rubber, but its a simple process I have been meaning to try.

Similar threads

- Replies

- 413

- Views

- 38K