Ooo.. Tool gloat time!

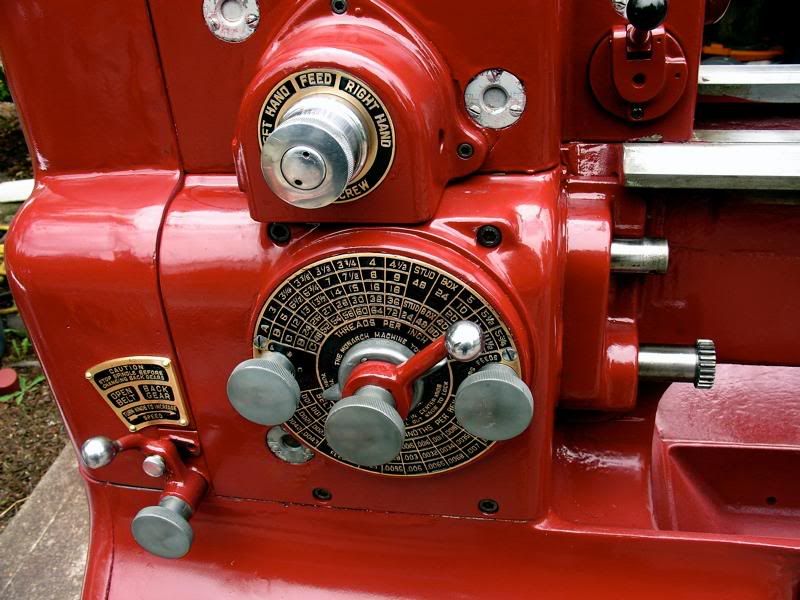

This Monarch was built in 06/1942 called a "Round Dial" for its round threading/feed selector dial. Originally a war machine it has tags internally from the Detroit Ordinance District. 0-2500 RPM infinitely adjustable 12.5" swing 20" between centers. With taper attach and threading stop built into cross feed screw. Came with 6 jaw Buck Adjust-tru, original 8" 3 jaw, 8" 4 jaw, 11" face plate, steady, follow, 5C collet nose and drawbar, traveldial (Replaced with DRO)

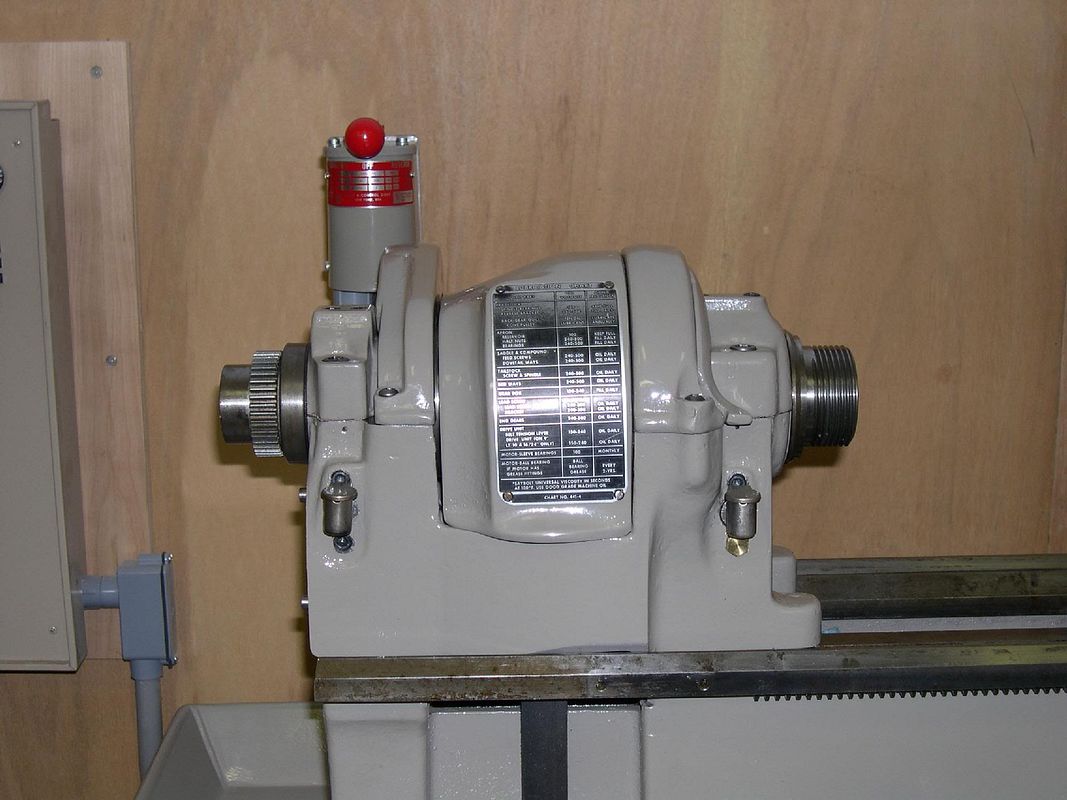

The 10EE began production in 1939 with a hydraulic variable speed drive which was replaced soon after with a Ward-Leonard style Motor-Generator variable speed system where a three phase motor runs a generator and an exciter which in turns runs a 3HP DC motor with an integral shifting gear box for a back gear. The drive is capable of accelerating 0 to 2500 rpm within 3 to 4 seconds and full stop in 2 seconds without a mechanical braking system.

Later the motor generator was upgraded to a vacuum tube based system which lasted until 1983. At that point it went to a solid state drive until recently where they switched to a 7.5hp ac motor with a VFD.

The lathe came out of the factory with .000030 spindle runout, less than .0005 per foot bed straightness. Oil pump in the apron lubes the ways as the saddle moves. Also an oil system in the tailstock. The spindle is separated from the motor by two large v belts to eliminate any motor vibration from getting into the spindle and affecting the finish. The gearbox is also driven by a flat belt when in feed mode to insure there is no gear train noise going back to the spindle as well. The spindle had built in forward/neutral/reverse selector do disengage the threading gearing when the lathe is not being used to thread. While cutting you can set a nicked on edge of the headstock and it will not move. All of this gives the finest finish of any lathe ever built to this day.

Think it as a heavier, larger swing version of a Hardinge HLV-H. Weighs over 3000 lbs. You can still buy one new from the factory today. About $80,000. A Factory rebuilt one is about 40 to 50k.

Heres a few more pics. First is when I had it set up for making windings to try and repair the coolant pump, middle pic is a spare drive system for it, and the last is a pic of when I got it a couple months ago.