C

compound driver

Guest

Hi

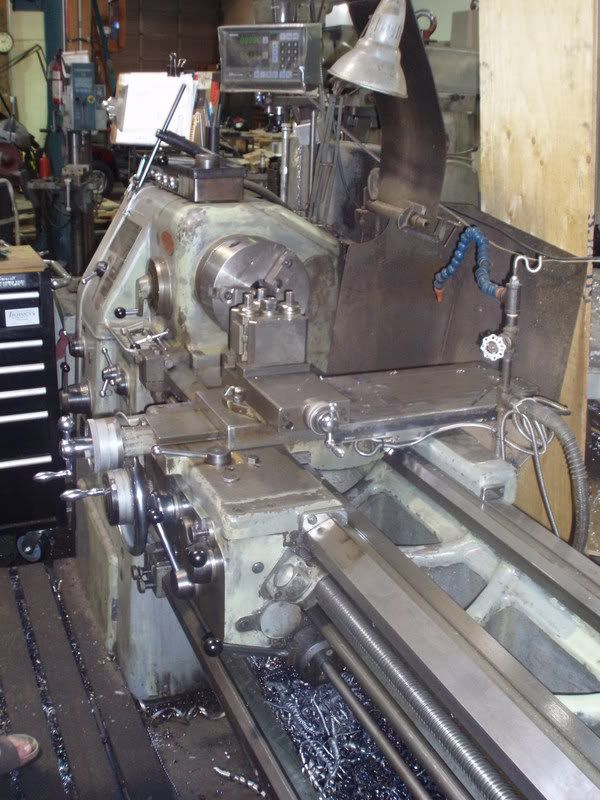

I did look at using a rotary setup rather than having three phase run in. The problem is with two mills and three lathes it gets a bit heavy on the 230volt woring not that all would be running at the same time but its not that rare for two to be going at the same time.

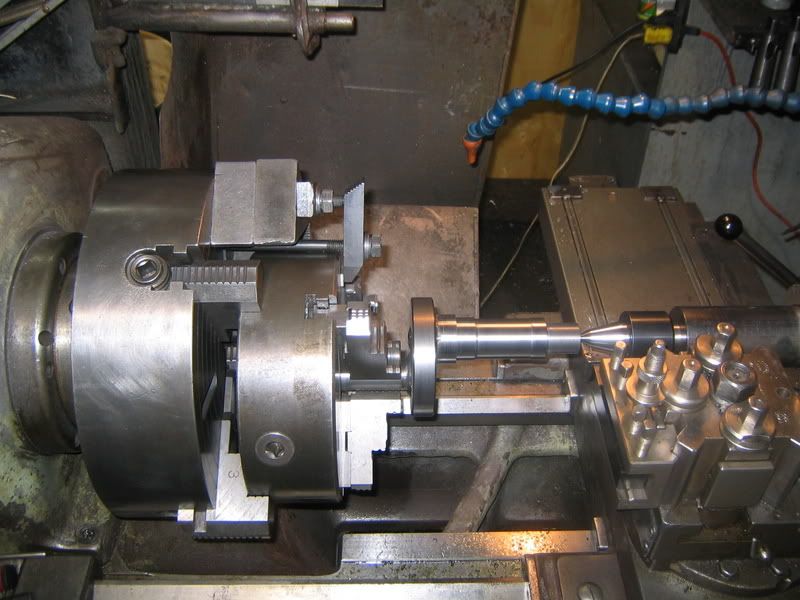

I thought a lot of the Logan it was a good solid accurate lathe. When it was bought we had that and a Van Norman 6a mill for $400 the pair. The seller had worked at the Newport news ship yards and didnt want anything to do with machines once he retired.

The VN i still say was worth two Bridgports there was more iron in the headstock of the VN than a complete J head. (ok maybe not but close).

Old American machine tools are very worth thinking about even given there age most will still do a good turn and for many years. The Vn mill still had beautifuly frosted ways and looked like it should work for years.

Cheers Kevin

I did look at using a rotary setup rather than having three phase run in. The problem is with two mills and three lathes it gets a bit heavy on the 230volt woring not that all would be running at the same time but its not that rare for two to be going at the same time.

I thought a lot of the Logan it was a good solid accurate lathe. When it was bought we had that and a Van Norman 6a mill for $400 the pair. The seller had worked at the Newport news ship yards and didnt want anything to do with machines once he retired.

The VN i still say was worth two Bridgports there was more iron in the headstock of the VN than a complete J head. (ok maybe not but close).

Old American machine tools are very worth thinking about even given there age most will still do a good turn and for many years. The Vn mill still had beautifuly frosted ways and looked like it should work for years.

Cheers Kevin