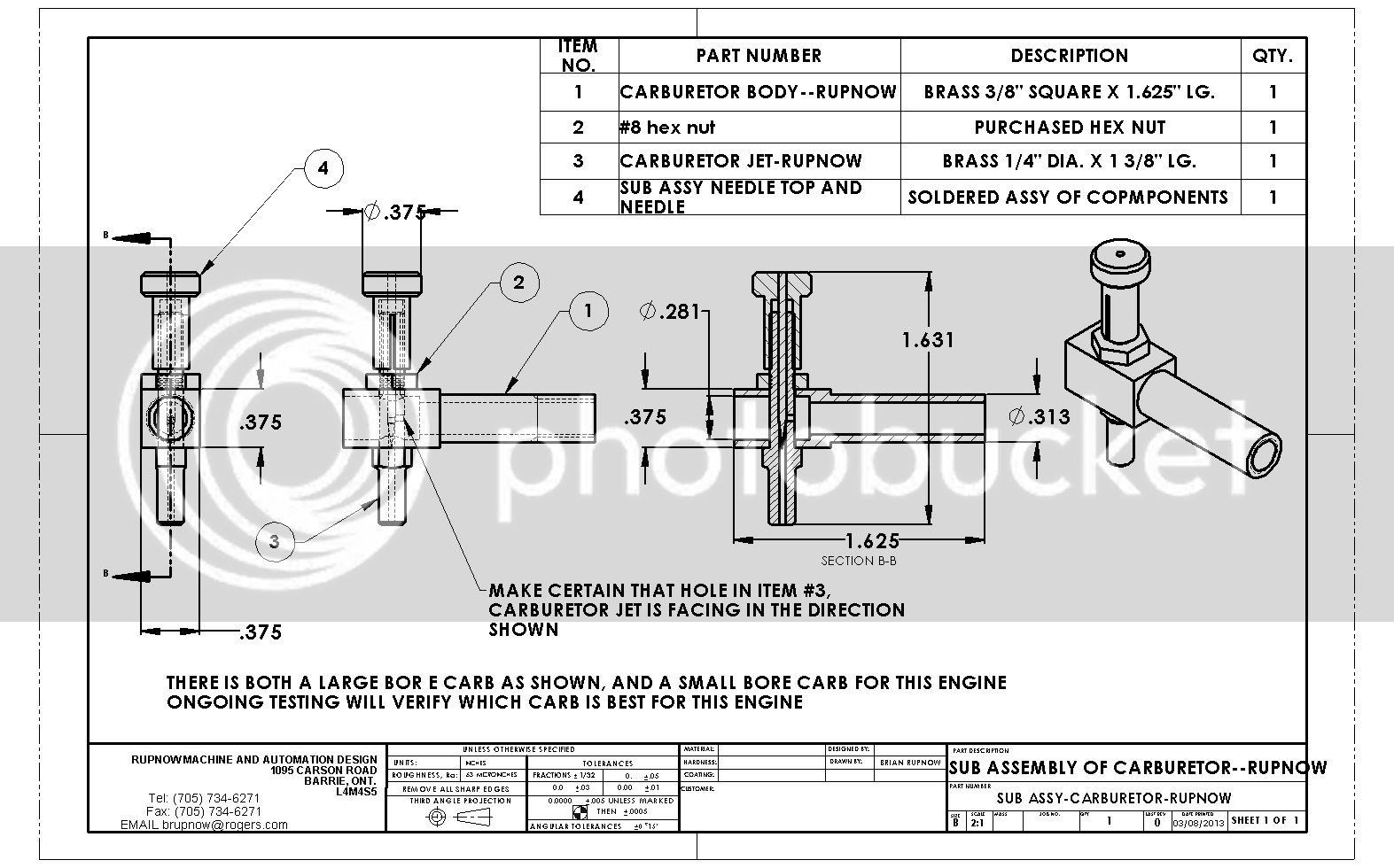

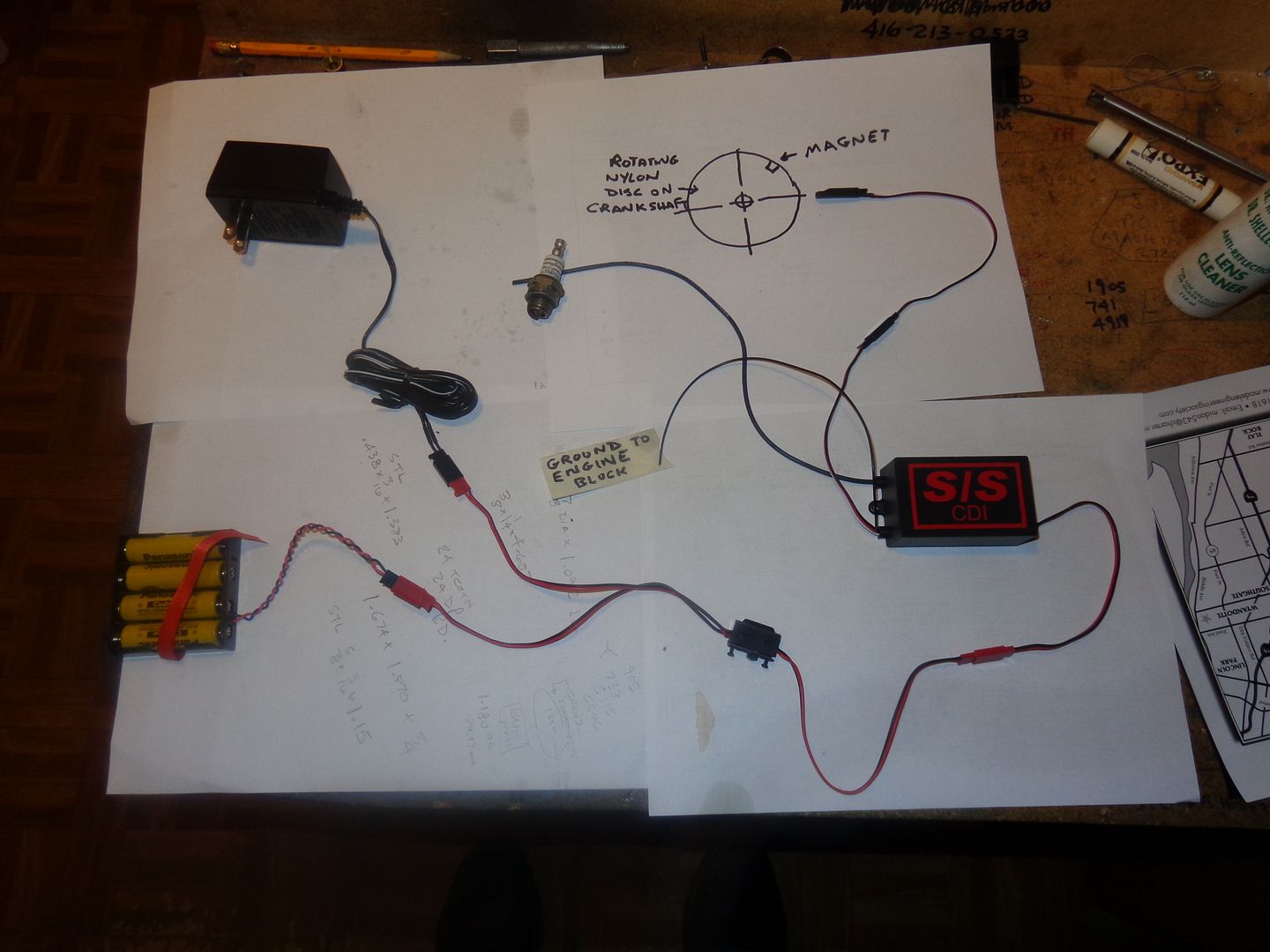

Pat---I am rather excited about this. I don't mean to imply by what I am doing that the Rupnow engine won't run satisfactorily with old style ignition points and coil. Its just that I have been wanting to try a CDI ignition for some time now, and this is an opportune time. I do know that the engine runs, as we all seen in the videos I posted, but I have my doubts about the coil and points I am using. If nothing else, this is hopefully going to settle the issue of ignition. If an engine runs, and there are no variables, then it should always start and run much the same, allowing for variations in temperature and fuel. I know beyond doubt that there are no mechanical variables. Having tried the smaller bore carb, and not seeing any real difference in "stability of performance", I will now have a go at the ignition.----Brian