You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rupnow i.c. Engine with governor

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Pat---There are only 3 or 4 pieces that are different to make the engine the cdi version. I will try zipping the individual pieces up and emailing them to you.---BrianBrian,

Any way that I can obtain the SW models for the CDI version?

Thanks,

Pat H

Kind of cool to see updates on 4 of your engines on the same night. You must be one proud papa.

Steve--I AM proud!!! Speaking as an "Old Guy", an observation that I can make is that as you get older, your world gets smaller and smaller. Creating a new engine and seeing it get built internationally is absolutely thrilling. I am really enjoying the responses and seeing this engine "come to life" all over the world. This is the most fun I've had in a long time.---Brian

Pat--the adjustable bracket for the hall effect switch picks up the right hand bolt hole that was originally one of the bolt holes for the points bracket. The other hole becomes redundant.

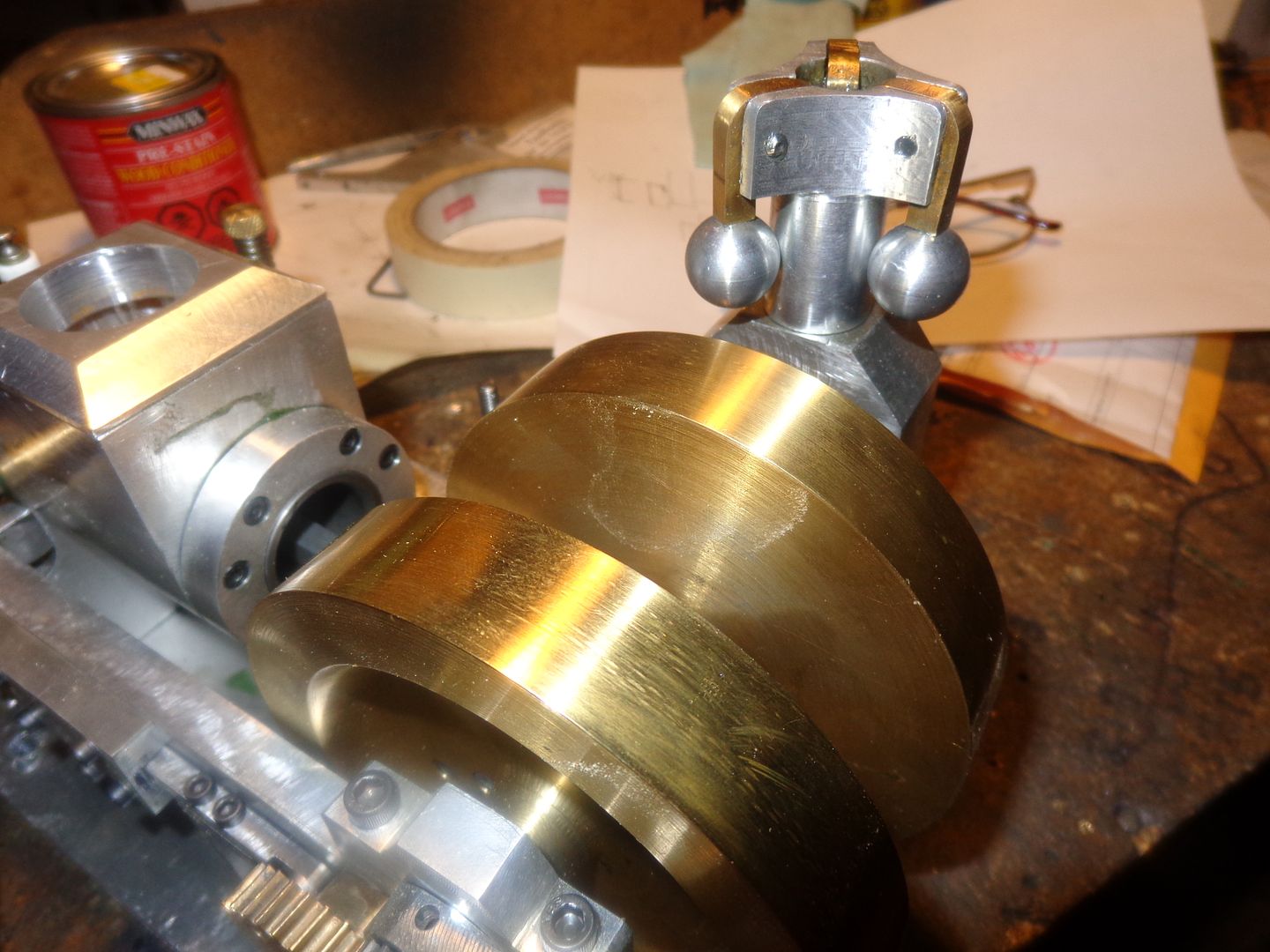

I've got balls!!! That's quite a statement, isn't it. What I meant to say, err---umphhhh----The 5/8" diameter aluminum balls I bought off E-Bay showed up today in the mail. Actually, I'm impressed. They look much better than the balls I tried to make. They have a 1/4-20 blind thread part way through, but I knew that and was expecting it. --I actually thought that the hole went all the way through, so the fact that they don't is a bonus. I think I ended up paying something outrageous, like $26 for the 3 of them, but hey--If you can't make them yourself, then you pay the price!!! I'm too busy playing box-maker right now to do anything with them, but when I get the box finished I will mount these on the engine.

Maybe somebody can check my math----This engine seems to have astonishing compression, to the point where I can barely turn it over by hand. I just ran a quick and dirty calculation, and it appears that the compression ratio is about 12.5:1---Maybe I've made a mistake. If not, that's an uncommonly high compression ratio for a hit and miss engine.

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

Maybe somebody can check my math----This engine seems to have astonishing compression, to the point where I can barely turn it over by hand. I just ran a quick and dirty calculation, and it appears that the compression ratio is about 12.5:1---Maybe I've made a mistake. If not, that's an uncommonly high compression ratio for a hit and miss engine.

did you just calculate the volume or did

you take exhaust cam in consideration

I just calculated the combustion chamber volume when the piston was at top dead center and the volume when the piston was at bottom dead center and divided the large number by the small one. From what I can gather after doing a bit of research is that on a flat top piston, my method of calculation is correct.--I'm not sure what Luc is referring to. I just did a bit of internet prowling, and it seems that compression ratio on original hit and miss engines was from 3.5:1 up to 5:1. This being the case, I have absolutely no idea of what effect the high compression ratio I have calculated will have on this engine. It starts. It runs. Seems to run fine, no pre ignition nor other visible problems. I suppose it is possible that the early engines had such low compression because they didn't have good quality gasoline and because most of these machines were started by hand.

Last edited:

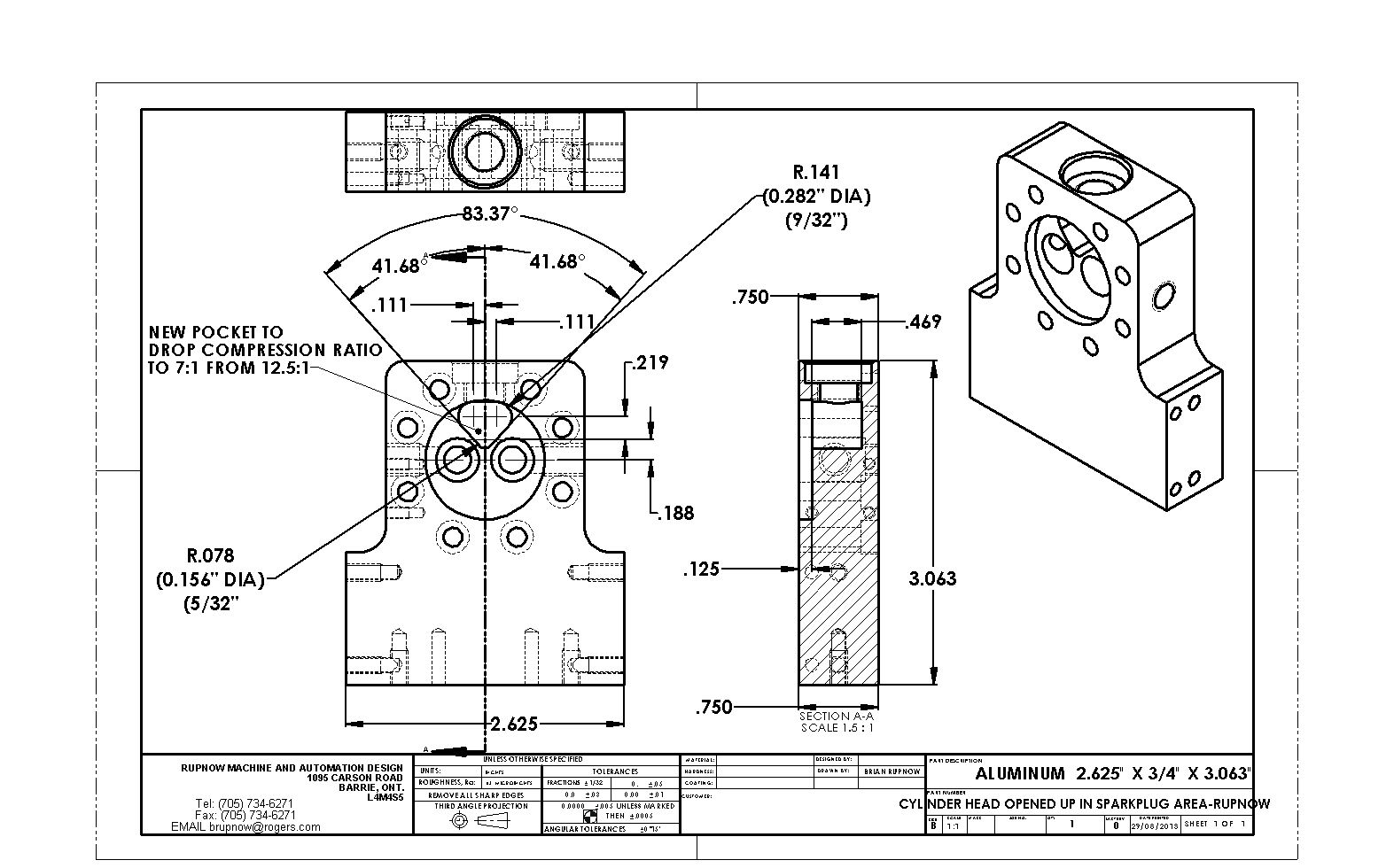

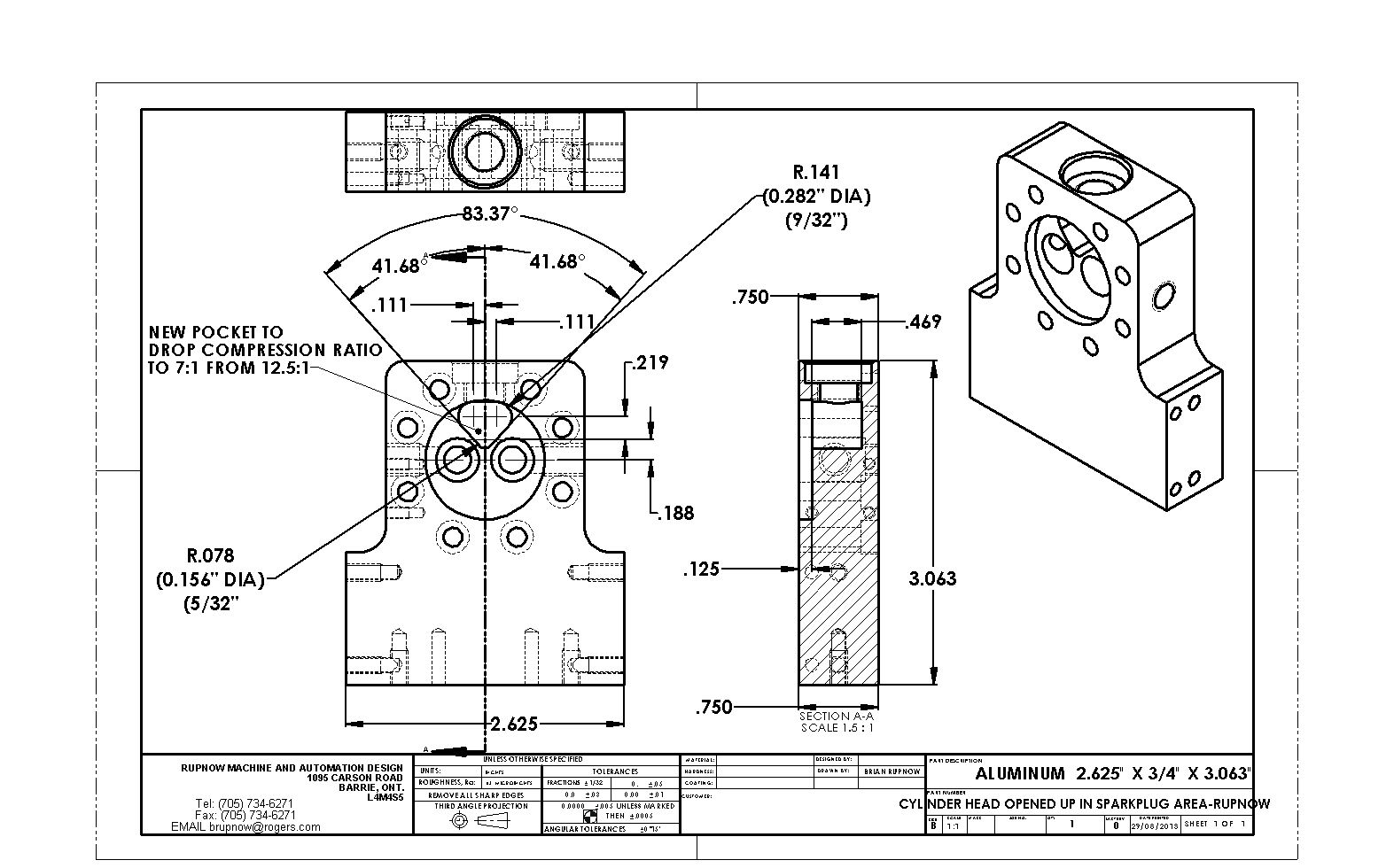

Back when I was initially trying to get my engine started for the first time, without much success, I thought --"Hmmm----Maybe Chuck Fellows was correct, and the sparkplug is too shrouded by metal to fire properly."---I spent a bit of design time attempting to come up with a way to open up the area around the sparkplug quite a lot, without having to make a new cylinder head. I was able to remove a lot of metal from around the sparkplug in the solid model, but then I managed to get the engine running okay, so never bothered with the modification to my engine. Last night after calculating that the current compression ratio is a whopping 12.5:1, I thought---"I wonder what I could do to lower the compression ratio?", and I remembered the modification I had made to the solid model of the cylinder head. As it turns out, that single modification to the cylinder head would serve two functions. It would certainly "unshroud" the sparkplug, and it would drop the compression ratio to 7:1 which is more in line with the compression ratios of the original hit and miss engines.---As of now, I have no intention of making that modification, because the engine runs fine, and I see no need to.--However, if I see at some point in the future that there is a problem with the high compression ratio, it is a fairly simple modification to the existing cylinder head to lower the compression ratio.

View attachment CYLINDER HEAD OPENED UP IN SPARKPLUG AREA-RUPNOW.PDF

View attachment CYLINDER HEAD OPENED UP IN SPARKPLUG AREA-RUPNOW.PDF

Last edited:

Brian

I've enjoyed your build. I do not know for sure, but I believe gasoline 30 years ago was a lot more volatile than it is today. It would clean oil based paint from brushes, today it will not. I don't believe there is any petroleum in it anymore. The compression of the old 1 lungers was low because they did not have starter like we have today. And that was the technology back then. Look at the model "T" it only had 6:1 compression, not like our engines today with much higher compression.

Again loved your builds.

Nelson Collar

I've enjoyed your build. I do not know for sure, but I believe gasoline 30 years ago was a lot more volatile than it is today. It would clean oil based paint from brushes, today it will not. I don't believe there is any petroleum in it anymore. The compression of the old 1 lungers was low because they did not have starter like we have today. And that was the technology back then. Look at the model "T" it only had 6:1 compression, not like our engines today with much higher compression.

Again loved your builds.

Nelson Collar

I had a little surprise today. All of the internal combustion engines I have built up to now, ( a total of 5) were test run on either my shop workbench or on the corner of the reference desk in my engineering office.---and they all were bolted down to be test run. Yesterday I finished the "Transportation and Display Case", and this morning I started the Rupnow Engine for its first run. My God, the Display Case base, which the engine is now bolted to, acted like it was possessed. It leapt up and down, shimmied from side to side, and took off travelling across my work bench. I thought for a minute I was going to have to chase it around the garage!!! I had never stopped to think how much unbalanced vibration these hit and miss engines created. I guess my next stop will be the hardware store to search out some anti-vibration feet to attach to the underside of the wooden base. Now I understand why so many of these hit and miss engines are bolted to little wagons with wheels on them. I am assuming the wheels allow the cart to roll back and forth a bit to dampen the vibrations from the engine.

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

All mine run away like that too. I will be watching the "master fixer" solve this problem. You always find a solution and I am always amazed.

Then I will copy (of course)

Jim

Then I will copy (of course)

Jim

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

I am assuming the wheels allow the cart to roll back and forth a bit to dampen the vibrations from the engine.

http://s307.photobucket.com/user/Br...005/ENGINEBOXFINISHED004_zpsd0b967e3.jpg.html

Hi Brian-- It looks good

as for the vibration the Wheel has nothing to do with the dampening

of the vibration.

the weight does it hall same thing when you bolt it to your workbench

the clamp does not damper the vibration but the weight of the bench does.

I think that if you mount the motor on 4 valve spring you will be able do cancel the vibration using different tension on the spring

I'm back to the build tomorrow check for pictures soon

I'm going to call this "The Last Post". The engine is finished. The "Transportation and Display" case is finished. The governor has its 5/8" diameter aluminum balls in place, and they seem to work fine. I must say, I am impressed with the electronic ignition. This is a build that has carried me through the summer, and its something new, and a little different. Thank you to all who tuned in, and had a look or something nice to say. I am going to set back now, and hopefully watch as other "Rupnow engines" come to life around the globe. ---Brian Rupnow

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

Hi Brian-- It looks good

as for the vibration the Wheel has nothing to do with the dampening

of the vibration.

the weight does it hall same thing when you bolt it to your workbench

the clamp does not damper the vibration but the weight of the bench does.

I think that if you mount the motor on 4 valve spring you will be able do cancel the vibration using different tension on the spring

I'm back to the build tomorrow check for pictures soon

The mass of the workbench stops the engine from moving. But the wheels work in a different way; they break the 'stiction' that causes the engine to move in one direction. The best example of wheels doing this in on the Trebuchets that the Romans used.

And you can see the full sized engines rocking gently back and forth on their wheels at the shows.

Jim

I'm having a "What if" moment. I've "improved" the engine as much as I can, in regards to carburation and ignition. (I went back to the small bore carburetor in the end). The only observation that I have, is that this engine floods very easily when you are trying to start it. ---and then it doesn't really clear itself that easily with more cranking, even with the fuel needle fully closed. In its current form, the sparkplug is setting back in a fairly narrow slot in the head. If I milled away the material which is shrouding the sparkplug, as shown in post #472, I wonder if that would help ease the flooding problem. I KNOW it would lower the compression, but I don't think there is any direct "cause and effect" between compression and flooding. Since this is a brand new "one of" engine, I simply don't have anything to compare it to form an opinion. All I can really do is wait until some more of the engines currently being built come "On line" and then compare notes with the builders..

Cogsy

Well-Known Member

Looks and runs great Brian. Just wondering why the water in your hopper is orange? Is it anti-corrosive or something similar? I was planning on using a tip I gained from this site and coating all surfaces which will come in contact with water with clear nail polish (the wife kindly donated a bottle but don't tell her). So far my Upshur has had the same hopper full of water for over 2 months and still doesn't show any signs of the ali hopper or cast iron cylinder corroding, but if you know a better way I'm all ears.

Similar threads

- Replies

- 28

- Views

- 4K

- Replies

- 27

- Views

- 3K

- Replies

- 61

- Views

- 8K