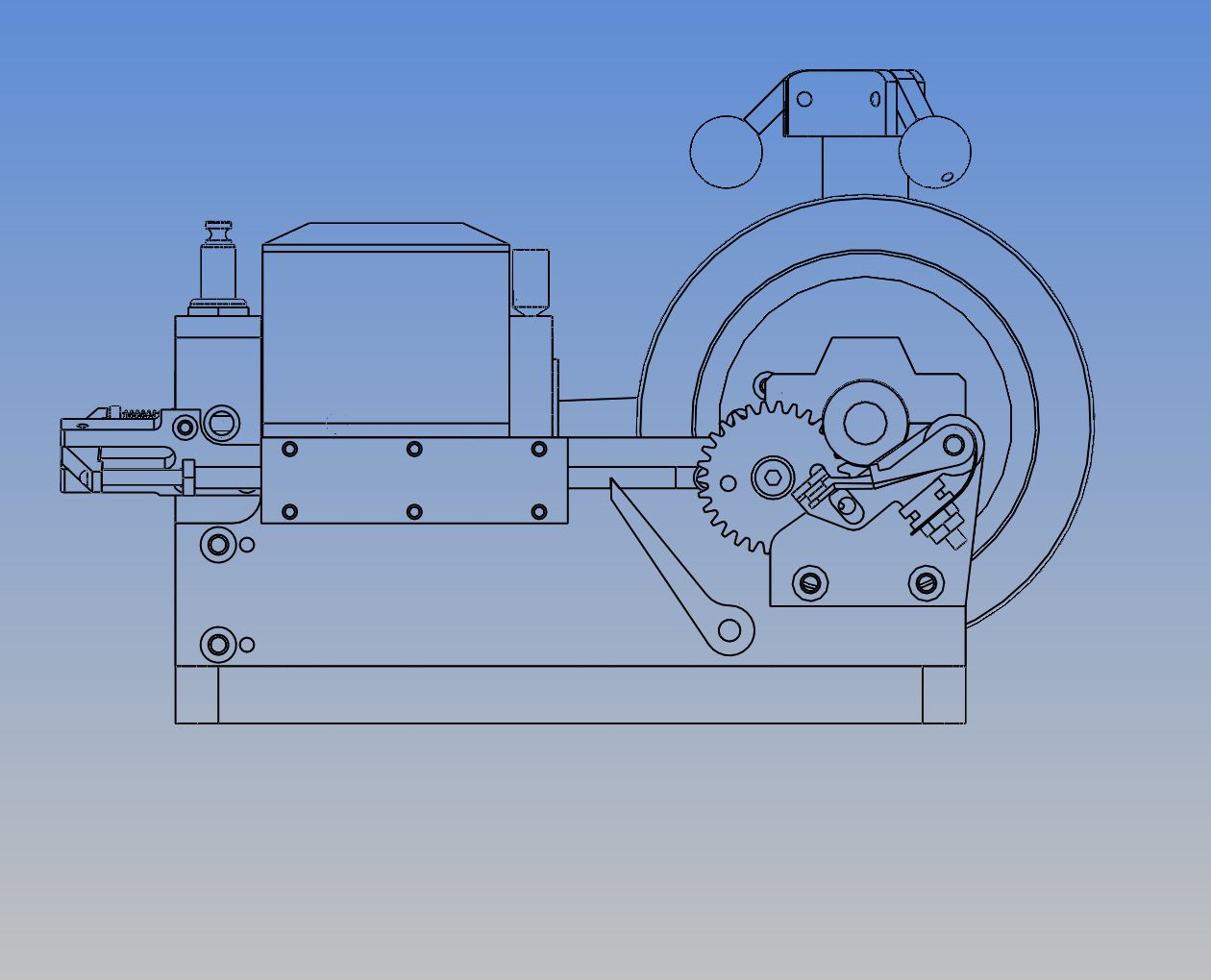

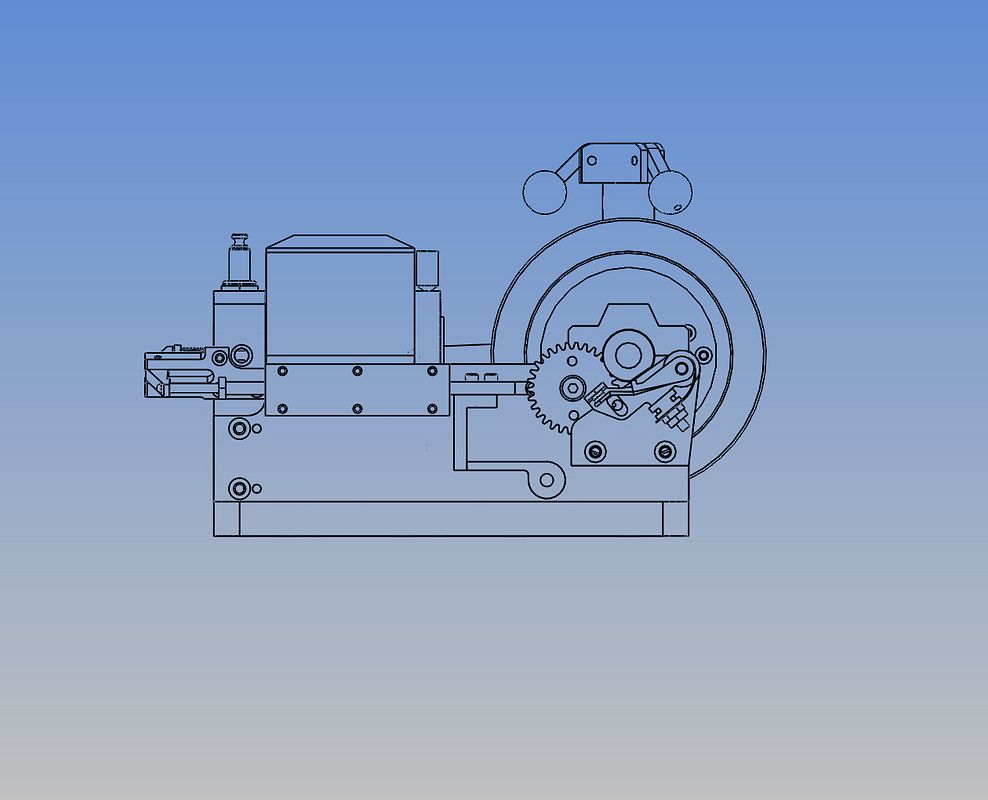

Good morning, my international engine building friends. After a long day spent in the shop yesterday with my new engine, its time for a report. Take heart--All of the major mechanical components work like a charm. That strange crankshaft/flywheel combination works very well. The single Viton ring give this thing all kinds of good compression. The valves seal very well, but I found that as usual I had both the intake and exhaust springs a bit too long and had to keep trimming them one coil at a time. You do this with the spring on the intake valve until, with the engine turning over at a good clip either by a belt driving motor or by your electric drill, you can see the exposed end of the valve start to "dance" as the suction from the intake stroke pulls it open. It won't move much, but it does have to move some.--otherwise your engine can't pull any air or fuel in for combustion. The exhaust valve spring has to be strong enough to hold the cam follower bearing in contact with the cam at all times, but not so strong that it causes undue wear on the face of the cam.--This is more a "seat of the pants" judgement call than anything. There are no clearance issues anywhere on the engine. The new ignition points mounting bracket that I had to design works well, and leaves the head of the shoulder bolt which holds the cam gear in place accessible so that it can be tightened adequately. I have been chasing a gremlin that seems to live in my carburetor, causing the engine to run fine for a while (you seen that in one of the videos I posted) and then without changing anything to not want to start at all. I assure you, this has nothing to do with the design of the engine, and everything to do with my carburetor building abilities. I did discover yesterday that the 5/8" diameter brass governor balls may be too heavy for the application. Don't rush out and buy any 5/8" brass balls at this stage of your build. I like the look of these balls "size wise" but they may end up being made of aluminum--I simply don't know yet. I have to do some more work on the governor mechanism. It works, but the steep angle that the latch mechanism sets on tends to wedge itself in place on the underside of the pushrod and not want to drop out when it should. I have a "fix" for that, and will be posting it this morning. Cheers, and keep up the great work I see being displayed in your posts.---Brian