- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Please recognize that this post contains a lot of personal opinion.

With all the machining done on the cylinder, the bore must be finished. For the hobby machinist there are two methods in common use, honing and lapping. So which did I use? I am not sure. The definitions of the two processes have been merging for some time, and differ some from one industry to another.

Traditionally, honing was defined as a process using vitrified stones to finish a bore. Lapping was defined as using a loose abrasive in a slurry.

In more modern times, honing definitions have expanded to include abrasive, mostly diamond, that has been bonded to a metal core. Electroplating nickel, like a diamond file, is a common way to bond. Sometimes the tool is is adjustable, or is less critical applications is it fixed. A common name for this process is single pass honing. Oil is normally used to wash out removed metal particles.

Lapping has also expanded, and is sometimes referred to as wet or dry lapping. Wet lapping is where a slurry of abrasive is used between the lapping tool and the part. Dry lapping is where the abrasive is pressed into the tool to impregnate it. The tool is then cleaned of all loose abrasive. Despite the name, dry lapping is not done dry. Oil or other liquid is used to wash out the metal particles as they are removed from the part.

So, at the overlapping point, the only difference between lapping and honing is is method used to secure the abrasive to the tool. I am going to call the process that I use lapping as it meets the definition of dry lapping.

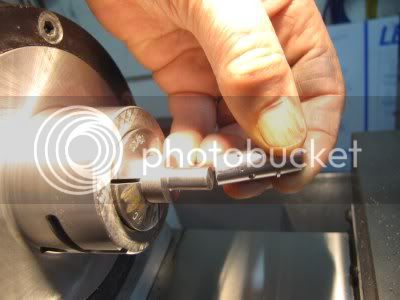

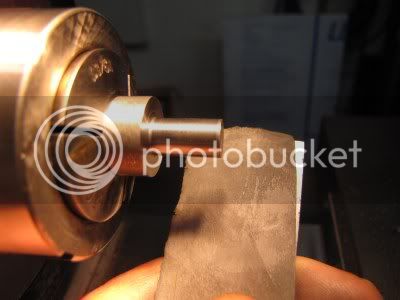

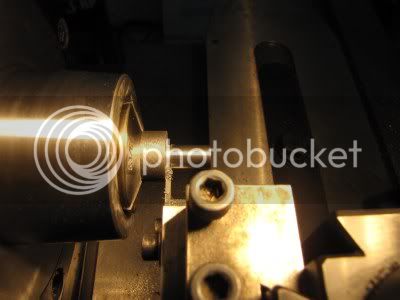

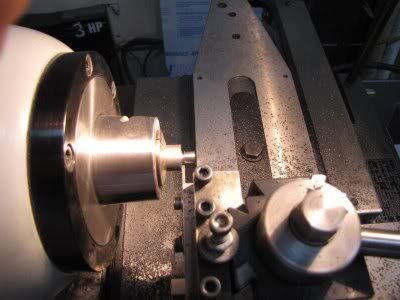

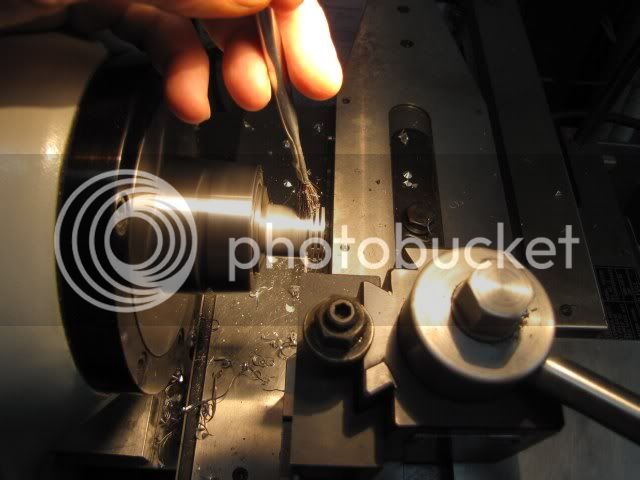

I used a pair of commercial expanding lapping tools with a brass barrel. As the operations are identical only one will be shown in the photos.

For abrasive, I use diamond lapping pastes. when dry lapping, I do not believe that diamond is worse about embedding in the work than the silicon carbide and other abrasives used in valve grinding compounds, or that it makes any difference. While some other abrasives will break down easier than diamond, if any abrasive of any kind is left in the bore, the piston/cylinder set will be worn out long before the abrasive breaks down.

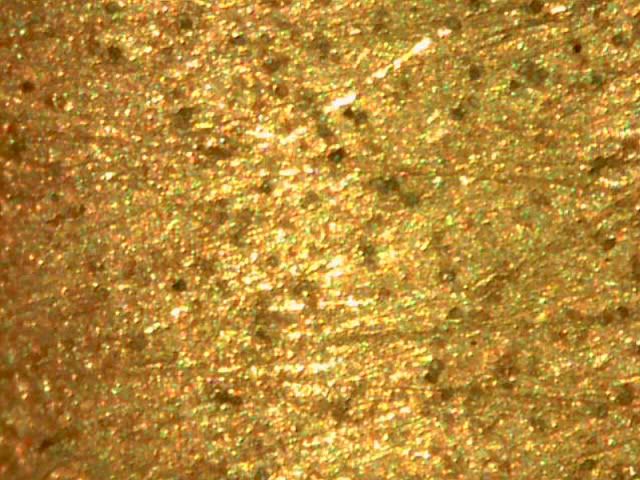

I use two different grades of diamond. Because the terminology used to grade abrasives can get confusing I am including more information than you probably want to know. The syringe in the photo is a 5 gram syringe. It is hard to see if any has been used. While I have not kept count, I have lapped over 20 cylinders from 1/4 to 3/4 inch bore with this syringe. A 5 gram syringe costs about US$20 at Enco. I do not expect to ever use up the contents of this syringe. The compounds I have are medium concentration. This is just how much diamond is mixed in. Light concentration would work just as well, but a little bit more of it would be used.

For roughing the cylinder, I use 600 mesh diamond. 600 mesh is roughly the equivalent of 380 grit if you compare it to wet-or-dry abrasive paper and the particle size is a nominal 30 micron, or about 0.0012 inch. This roughly is the same as Clover compound 1A.

To finish the cylinder, I use 1800 mesh diamond. 1800 mesh is roughly the same as 800 or 1000 grit wet-or-dry and the particle size is a nominal 10 micron or about 0.0004 inch. This roughly is the same as Clover compound 5A or 6A.

The Clover compounds referenced are silicon carbide, not diamond.

End of opinion and background information. Next post will be the how-to part.

With all the machining done on the cylinder, the bore must be finished. For the hobby machinist there are two methods in common use, honing and lapping. So which did I use? I am not sure. The definitions of the two processes have been merging for some time, and differ some from one industry to another.

Traditionally, honing was defined as a process using vitrified stones to finish a bore. Lapping was defined as using a loose abrasive in a slurry.

In more modern times, honing definitions have expanded to include abrasive, mostly diamond, that has been bonded to a metal core. Electroplating nickel, like a diamond file, is a common way to bond. Sometimes the tool is is adjustable, or is less critical applications is it fixed. A common name for this process is single pass honing. Oil is normally used to wash out removed metal particles.

Lapping has also expanded, and is sometimes referred to as wet or dry lapping. Wet lapping is where a slurry of abrasive is used between the lapping tool and the part. Dry lapping is where the abrasive is pressed into the tool to impregnate it. The tool is then cleaned of all loose abrasive. Despite the name, dry lapping is not done dry. Oil or other liquid is used to wash out the metal particles as they are removed from the part.

So, at the overlapping point, the only difference between lapping and honing is is method used to secure the abrasive to the tool. I am going to call the process that I use lapping as it meets the definition of dry lapping.

I used a pair of commercial expanding lapping tools with a brass barrel. As the operations are identical only one will be shown in the photos.

For abrasive, I use diamond lapping pastes. when dry lapping, I do not believe that diamond is worse about embedding in the work than the silicon carbide and other abrasives used in valve grinding compounds, or that it makes any difference. While some other abrasives will break down easier than diamond, if any abrasive of any kind is left in the bore, the piston/cylinder set will be worn out long before the abrasive breaks down.

I use two different grades of diamond. Because the terminology used to grade abrasives can get confusing I am including more information than you probably want to know. The syringe in the photo is a 5 gram syringe. It is hard to see if any has been used. While I have not kept count, I have lapped over 20 cylinders from 1/4 to 3/4 inch bore with this syringe. A 5 gram syringe costs about US$20 at Enco. I do not expect to ever use up the contents of this syringe. The compounds I have are medium concentration. This is just how much diamond is mixed in. Light concentration would work just as well, but a little bit more of it would be used.

For roughing the cylinder, I use 600 mesh diamond. 600 mesh is roughly the equivalent of 380 grit if you compare it to wet-or-dry abrasive paper and the particle size is a nominal 30 micron, or about 0.0012 inch. This roughly is the same as Clover compound 1A.

To finish the cylinder, I use 1800 mesh diamond. 1800 mesh is roughly the same as 800 or 1000 grit wet-or-dry and the particle size is a nominal 10 micron or about 0.0004 inch. This roughly is the same as Clover compound 5A or 6A.

The Clover compounds referenced are silicon carbide, not diamond.

End of opinion and background information. Next post will be the how-to part.