In post 62 I detailed how to make the compression limiting sleeve, but I did not give all the reasons for using one. After all, most of the commercial compression ignition engines do not have any means to limit the contra piston position. The only really early popular engines that I remember that did so were the OK Cub engines.

If you read the early operating instructions of the commercial engines, most caution against using an electrical starter. That is fine advice, but if you watched the IMP video you know that I used a starting motor. About a dozen years ago I found that I could either hand prop engines or the next day I could raise my arm enough to do machining in the shop. NOT both.

When hand starting a small engine you can feel if a hydraulic lock is developing or if the compression is set too high. You lose this feel using an starting motor.

On V3 of the IMP, I fitted the piston a little bit loose, but thought I would try running it anyway. Not really loose, just that the pinch point on the piston position was about a tenth of an inch higher than it should be. So the piston was really less than 0.0001 inch too small. Thats too much for small CI engines like the IMP.

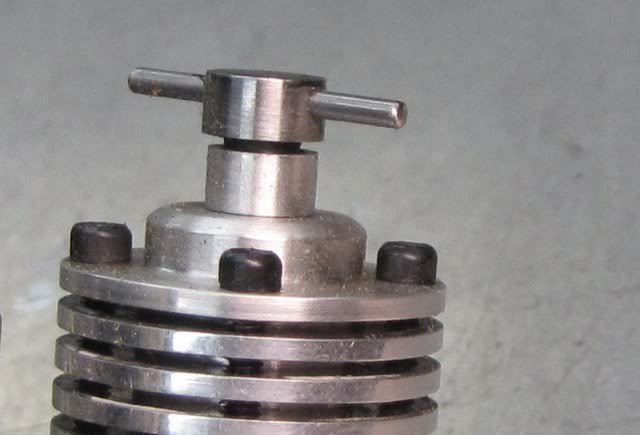

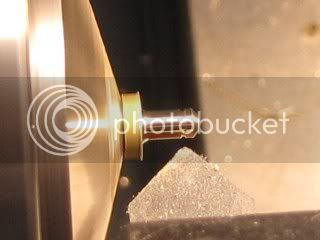

Since I was just trying it, I did not make up the compression limiting sleeve. I lost track of the position of the contra piston and ran the compression screw down a little too far while tinkering with start up. Since the con rod is the weakest link in these engines, the photo shows the result.

:-[

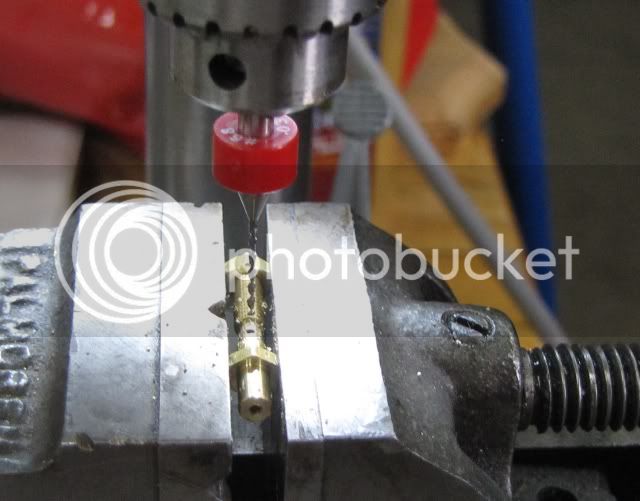

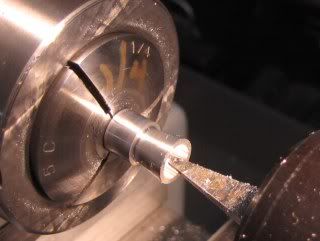

New piston, properly fitted, and a new con ron and all was well. ;D

Gail in NM,USA