I apologise for not posting on this for some time. One way or another I've been very busy with work and stuff.

At any rate I manged to make the carby and the ignition. For the ignition system I used the hall effect system with coil from J. Howell's site. The coil is the one on the top of this page,

http://www.model-engine-plans.com/partskits/ignitionsystems/coil.htm

The spark plug is just a little Honda one with a 10mm thread.

The good news is I managed to get the engine to run for a sustained period. Eventually I switched it off because it was getting hot and I don't have the water cooling system made yet.

The bad news is it is still very difficult to get to run and when it was running it ran super rough.

I have two thoughts about what to try next to improve how well it runs

1) I used 4 AA batteries to power the ignition at 6V. The spark was a decent blue colour but it seems rather small. I'm thinking I might get a stronger spark with a larger battery. I have very little experience at this, so the question. Should it run properly with 4 x AA batteries or are they too small?

2) The second thought is I could probably improve the lapping of the inlet valve. The engine seems to kick back like a mule when I try to start it though. Seems to have good compression.

Anyway I'm keen to hear some suggestions. I'll try and get some pictures soon :-[

Thanks in advance

Steve

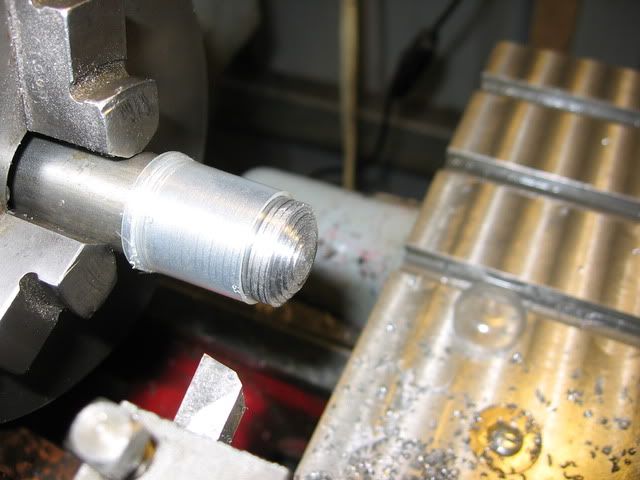

Many indexable carbide tips won't get a good finish with light cuts, so it might not just be the speed.

Many indexable carbide tips won't get a good finish with light cuts, so it might not just be the speed.