- Joined

- Nov 14, 2009

- Messages

- 675

- Reaction score

- 104

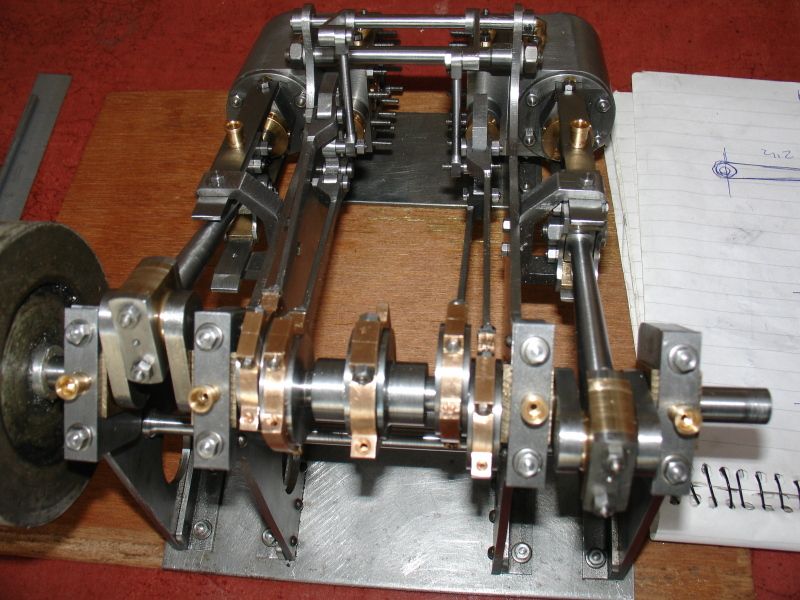

Yet more progress ,I must be on a bonus

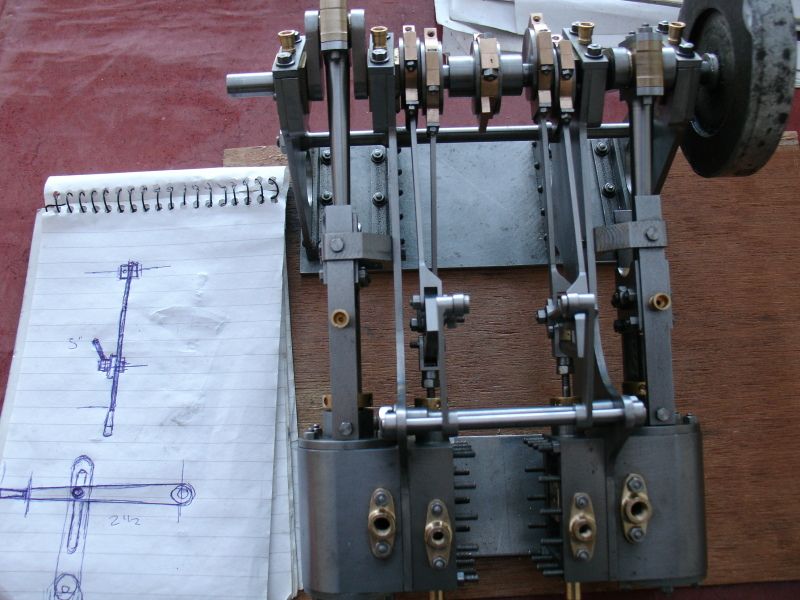

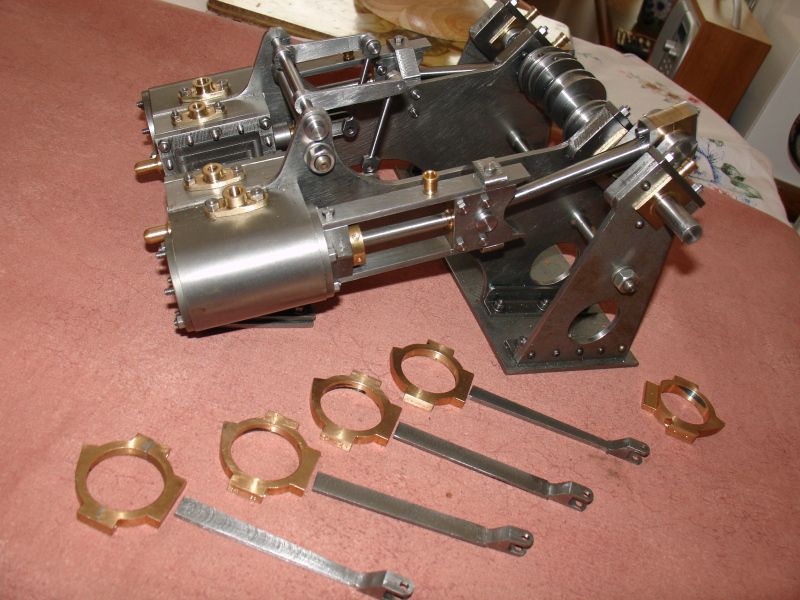

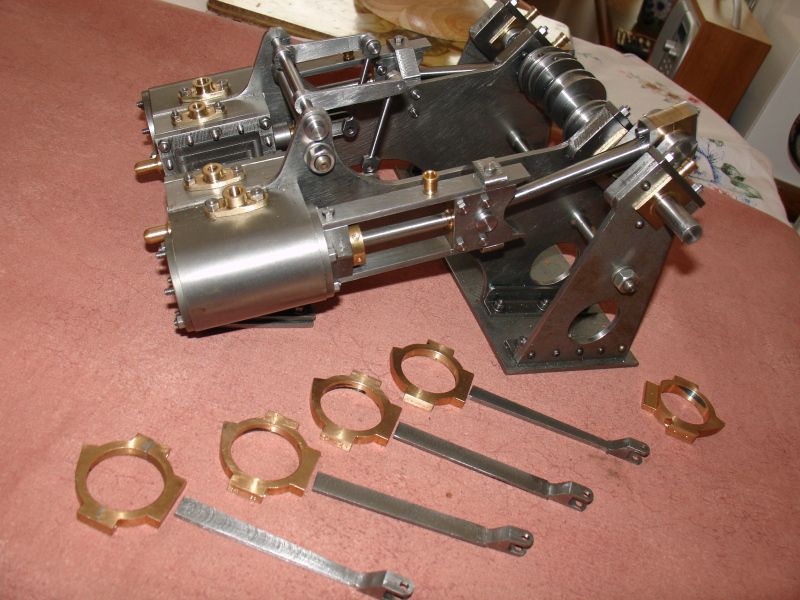

Those eccentric arms need a lot of hours,so I thought they warrent another pic,still more work to do on them,the end plates and finishing off.Had enough for today so Ill have a look at the Olympics.

Don

Those eccentric arms need a lot of hours,so I thought they warrent another pic,still more work to do on them,the end plates and finishing off.Had enough for today so Ill have a look at the Olympics.

Don