- Joined

- Nov 14, 2009

- Messages

- 675

- Reaction score

- 104

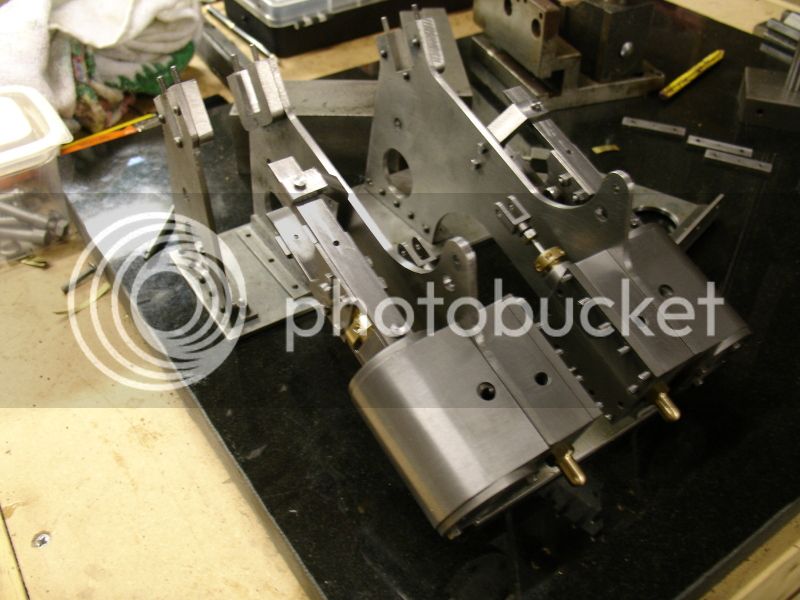

My cast iron came yesterday

Thats for 2 cylinders 2 steam chests and the cyl covers.

Started machining today and guess what,the plastic high low gear snapped on the minni mill ,I know,I know i should have gone to belt drive.New gear coming tomorrow.

I have a new Combi boiler coming tomorrow as well,so its that first I'm afraid.

Don

Thats for 2 cylinders 2 steam chests and the cyl covers.

Started machining today and guess what,the plastic high low gear snapped on the minni mill ,I know,I know i should have gone to belt drive.New gear coming tomorrow.

I have a new Combi boiler coming tomorrow as well,so its that first I'm afraid.

Don