I've been reading my posts from when I built the Poppin engine a few years ago, sorting out the timing of the slide valve that opens and closes the cylinder port. Thankfully, I give a good written description of the timing sequence during that build. The Poppin engine had no exhaust valve on it, as due to the design if any positive pressure built up in the cylinder, it just blew off pressure by lifting the very thin gauge valve plate off it's seat. I may have to add an exhaust valve to my engine to make it run properly, but I will first try to run it with no exhaust valve. Fortunately, the exhaust valve is not difficult to build.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My next build--A cross beam vacuum engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

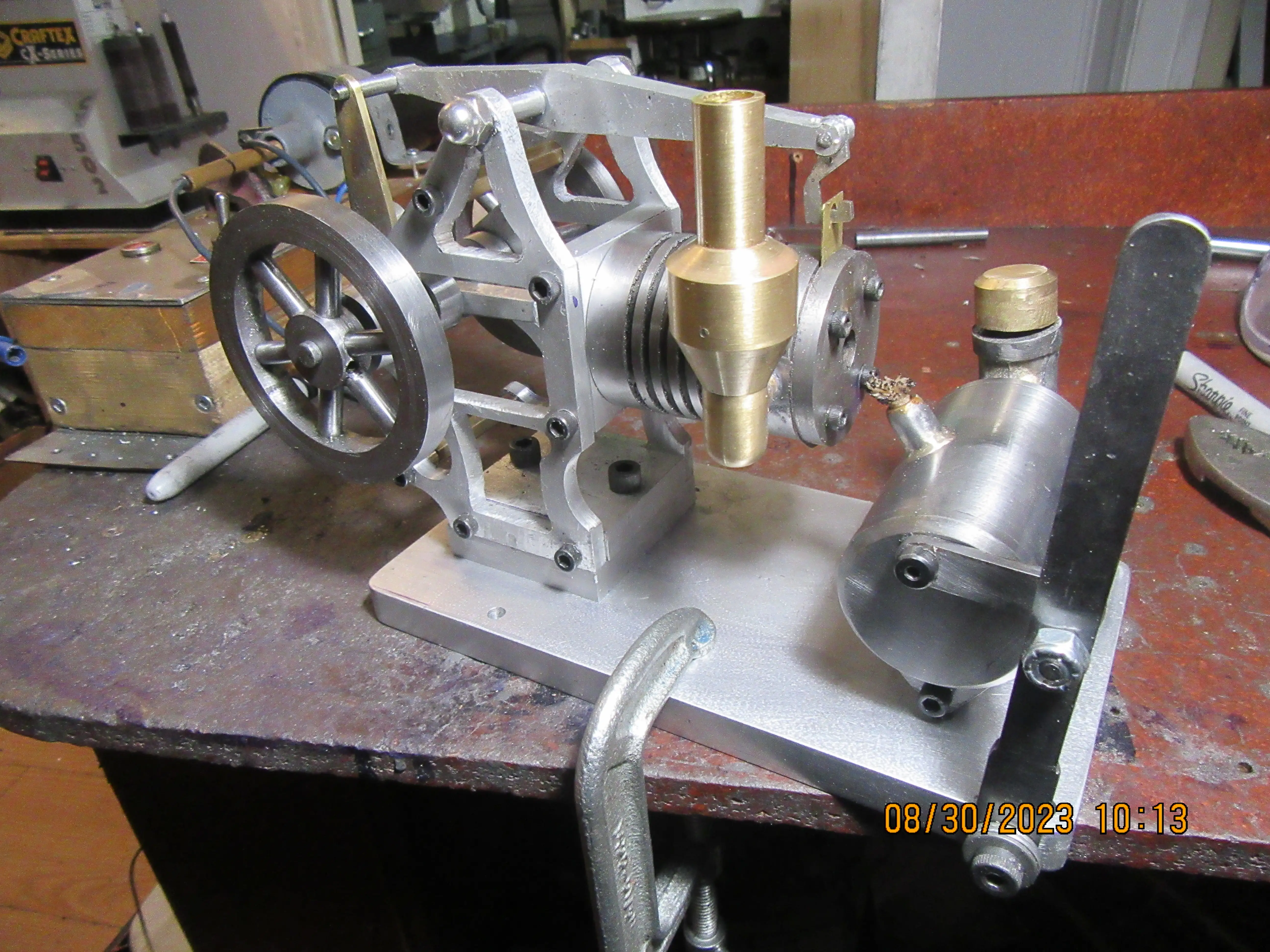

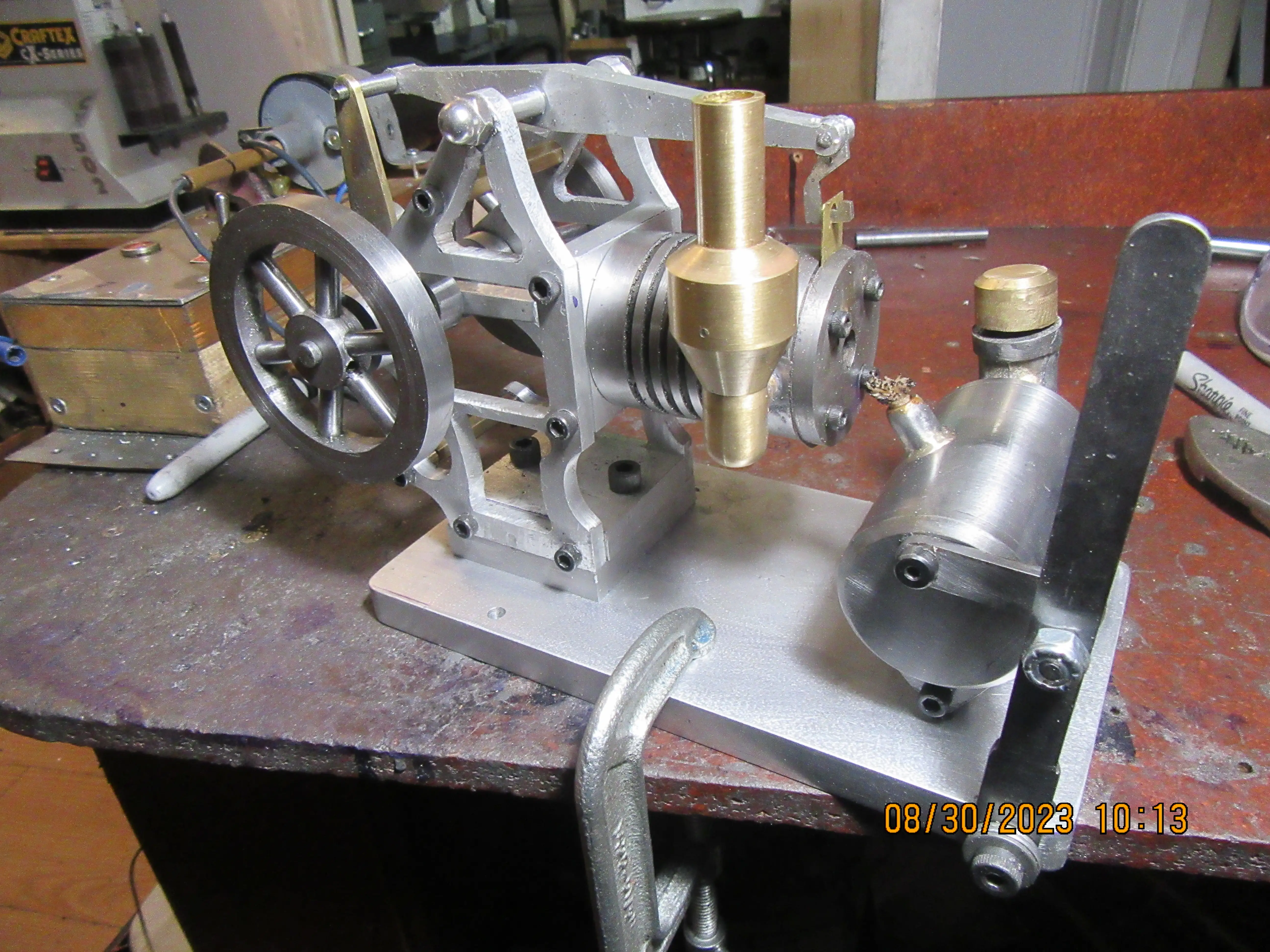

Just because I could---I've built a brass smokestack and installed it on my engine. It's a trick, no smoke comes out of it, but--under some conditions, the piston returning to top dead center will blow out thru the hole in the front of the cylinder and blow out the flame. This "smokestack" actually has a ball type poppet valve inside it, so when the piston is comin up to top dead center it lifts the ball of the seat and blows any pressure out thru the smokestack. Then when the piston moves towards bottom dead center, the ball seats in a cone inside the smokestack and prevents any air being sucked into the cylinder.

Looking forward to seeing it run.

I suspect the flame is too high if it is blown-out by the "whoof!" when the valve opens... , causing the engine to suck-in the vapour from the wick, rather that very hot burning gases above the blue cone...? Or timing is a bit wrong to cause the "Whoof"? (visible in the video in post #1)

Surely the valve should only open when the pressure is slightly sub-atmospheric..... as it is expected that the cooling gases become sub-atmospheric, then the piston is pushed up the cylinder by atmospheric pressure... when the valve should then open somewhere about TDC for the piston to suck-in more flame? - see this video..?

AND: If the zone of un-burned fuel vapour adjacent to the wick is in-line with the inlet port, it will be blown-away by any "Whoof!", but if the flame is lower and the combusting gases around the top of the blue cone are sucked in then the gas envelope around the wick should remain alight.... Really, I reckon you should try and suck-in the top half of the flame, not the bottom half - is my guess?

But the video in Post#1 looks like the flame is all around the wick, but the wick is high enough so the "whoof" blows against the wick, allowing the flame behind the wick to be protected from blowing-out....

Brian, I have not had any success making my Chinese toy model work anyway, so my theory is probabubly "Bunkum!" anyway!

Watching with bated breath to see what "the Master" does to make it really work!

Cheers,

K2

Surely the valve should only open when the pressure is slightly sub-atmospheric..... as it is expected that the cooling gases become sub-atmospheric, then the piston is pushed up the cylinder by atmospheric pressure... when the valve should then open somewhere about TDC for the piston to suck-in more flame? - see this video..?

AND: If the zone of un-burned fuel vapour adjacent to the wick is in-line with the inlet port, it will be blown-away by any "Whoof!", but if the flame is lower and the combusting gases around the top of the blue cone are sucked in then the gas envelope around the wick should remain alight.... Really, I reckon you should try and suck-in the top half of the flame, not the bottom half - is my guess?

But the video in Post#1 looks like the flame is all around the wick, but the wick is high enough so the "whoof" blows against the wick, allowing the flame behind the wick to be protected from blowing-out....

Brian, I have not had any success making my Chinese toy model work anyway, so my theory is probabubly "Bunkum!" anyway!

Watching with bated breath to see what "the Master" does to make it really work!

Cheers,

K2

All work on the engine has finished. Engine is trying to run, but not quite making it. Methinks the flame is set too high in relationship to the hole in the cylinder plate. Will address that by machining a 1/4" pocket out of the main baseplate where the tank sets tomorrow.

I'm remembering back to when I built the "Poppin" engine. There was a problem with "Over the counter" alcohol. The strongest alcohol you can buy is 70% strength. The other 30% by volume is made up from water, which mixes just fine with alcohol, but the flame that results from burning it is not particularly hot. I remember at the time, ordering a container of 99% alcohol from my druggist, and that burns with a much hotter flame. Of course I spent an hour today searching for the remains of that bottle from five years ago, but couldn't find it anywhere. So--I just called my druggist to order another bottle of 99% and it will be here Thursday. So---tomorrow I will make a "well" 1/4" or 5/16" deep in the engine baseplate to lower the alcohol tank.

- Joined

- Jan 4, 2011

- Messages

- 1,334

- Reaction score

- 344

Use gasoline anti freeze HEET in the yellow bottle. Red will not work. I used it in my backpacking stove. I am sure that is available in Canada.I'm remembering back to when I built the "Poppin" engine. There was a problem with "Over the counter" alcohol. The strongest alcohol you can buy is 70% strength. The other 30% by volume is made up from water, which mixes just fine with alcohol, but the flame that results from burning it is not particularly hot. I remember at the time, ordering a container of 99% alcohol from my druggist, and that burns with a much hotter flame. Of course I spent an hour today searching for the remains of that bottle from five years ago, but couldn't find it anywhere. So--I just called my druggist to order another bottle of 99% and it will be here Thursday. So---tomorrow I will make a "well" 1/4" or 5/16" deep in the engine baseplate to lower the alcohol tank.

krypto

Well-Known Member

Just buy denatured alcohol at the paint/home improvement store. The can will probably also be marked as fuel for marine stoves. It's what I use to get my kerosene pressure lanterns started.

That is, of course, assuming it's not banned in Canada as it is in California.

That is, of course, assuming it's not banned in Canada as it is in California.

gartof

Well-Known Member

- Joined

- Mar 13, 2011

- Messages

- 45

- Reaction score

- 14

What you need is isopropyl alcohol it is 99% alcohol and pretty widely available.I'm remembering back to when I built the "Poppin" engine. There was a problem with "Over the counter" alcohol. The strongest alcohol you can buy is 70% strength. The other 30% by volume is made up from water, which mixes just fine with alcohol, but the flame that results from burning it is not particularly hot. I remember at the time, ordering a container of 99% alcohol from my druggist, and that burns with a much hotter flame. Of course I spent an hour today searching for the remains of that bottle from five years ago, but couldn't find it anywhere. So--I just called my druggist to order another bottle of 99% and it will be here Thursday. So---tomorrow I will make a "well" 1/4" or 5/16" deep in the engine baseplate to lower the alcohol tank.

For testing why not just use a propane torch then when you know the engine works sort out the burner/fuel. It is also a lot easier to adjust flame size and position with a handheld torch so you can find the sweet spot like I am here.

Where did you get that information ?Surely the valve should only open when the pressure is slightly sub-atmospheric..... as it is expected that the cooling gases become sub-atmospheric, then the piston is pushed up the cylinder by atmospheric pressure... when the valve should then open somewhere about TDC for the piston to suck-in more flame? - see this video..?

K2

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

Denatured alcohol. you can buy it at lowes or home depot in the USA not sure about in Canada. often called "Fuel" and i find it in the paint thinner isle. thats what i run my flame eater on. about 15.00 for a gallon of the stuff

The valve opens as the piston approaches TDC. All the contraction of the hot gas has occurred and the valve lets out the last bit that starts to get compressed by the piston. Makes for a much freer running engine and also helps stop the flame being blown out.

Here is another of mine, block the exhaust and it does not run for long

Here is another of mine, block the exhaust and it does not run for long

I laid in bed last night and decided that it would be far easier to raise the engine up 3/8" than to mill a pocket in the base. It achieves the same effect, raising the flame port in the cylinder 3/8" higher than it was before, and doesn't affect the Casey Jones linkage.

Surely the valve should only open when the pressure is slightly sub-atmospheric..... as it is expected that the cooling gases become sub-atmospheric, then the piston is pushed up the cylinder by atmospheric pressure... when the valve should then open somewhere about TDC for the piston to suck-in more flame? - see this video..?

Cheers,

K2

Ah you are confusing the exhaust valve that Brian has just added within the muffler with the shutter that opens and closes the inlet to allow the flame to be sucked in..

The engine is finished and I have my 99% alcohol. The engine wants very badly to run, but isn't quite there yet. I have flipped the flywheel manually enough times that the cylinder is hot from sucking in the flame, but no running yet. Tomorrow is a new day, and I have one trick I haven't tried yet. I'll let you know what my results are tomorrow.

Jason, Minth,

My valve timing knowledge of these engines is just guesswork! This is the first post I have seen with engines that have/need an exhaust valve to exhaust excess pressure in them. Curiously, of the many videos I have seen, - all without separate exhaust valves - there are very few that show any blow-back.... I was simply assuming that there really wasn't much pressure/gas to blow-back as it had cooled "to develop the vacuum"?

Perhaps there is some ratio of inlet port size to cylinder size (piston diameter?) that means some engines suck-in more flame than others, so have more spent gas to expel - and if they have small inlet ports this will emit a jet of dead gas which could blow-out the flame?

I read (years ago... memory imperfect?) that these atmospheric "hot air" engines pre-dated internal combustion engines (Like Newcomen's, etc., Atmospheric engines pre-dated internal steam pressure driven engines). They used the flames and smoke (hot gases) from Coking ovens is steel making plant as there was a huge demand for process blowing air.... (through the molten metal to make steel?), and the "flame eaters" were a cheap way for an engine to drive the compressors/blowers. Otherwise, that flame & hot exhaust smoke from the coke ovens was simply lost up the chimley. - The disadvantage being the dirty exhaust gases from coke ovens contained lots of abrasive smoke particles that wore the engines badly and quickly... So they wanted engines that ran from cleaner coal-gas from the coke ovens (I.E. Water-gas from spraying water/steam onto red-hot coals mostly CO and H2). -SO, enter Otto and his infernal combustion engine designs that made dirty, smoke-driven flame-eaters obsolete.

K2

My valve timing knowledge of these engines is just guesswork! This is the first post I have seen with engines that have/need an exhaust valve to exhaust excess pressure in them. Curiously, of the many videos I have seen, - all without separate exhaust valves - there are very few that show any blow-back.... I was simply assuming that there really wasn't much pressure/gas to blow-back as it had cooled "to develop the vacuum"?

Perhaps there is some ratio of inlet port size to cylinder size (piston diameter?) that means some engines suck-in more flame than others, so have more spent gas to expel - and if they have small inlet ports this will emit a jet of dead gas which could blow-out the flame?

I read (years ago... memory imperfect?) that these atmospheric "hot air" engines pre-dated internal combustion engines (Like Newcomen's, etc., Atmospheric engines pre-dated internal steam pressure driven engines). They used the flames and smoke (hot gases) from Coking ovens is steel making plant as there was a huge demand for process blowing air.... (through the molten metal to make steel?), and the "flame eaters" were a cheap way for an engine to drive the compressors/blowers. Otherwise, that flame & hot exhaust smoke from the coke ovens was simply lost up the chimley. - The disadvantage being the dirty exhaust gases from coke ovens contained lots of abrasive smoke particles that wore the engines badly and quickly... So they wanted engines that ran from cleaner coal-gas from the coke ovens (I.E. Water-gas from spraying water/steam onto red-hot coals mostly CO and H2). -SO, enter Otto and his infernal combustion engine designs that made dirty, smoke-driven flame-eaters obsolete.

K2

What kind of alcohol? There are 3 common ones, methyl, isopropanol and ethanol. Each has different burn characteristics.The engine is finished and I have my 99% alcohol.

Considering you got yours from a drug store I assume its isopropanol (aka rubbing alcohol).

Last edited:

aka9950202

Well-Known Member

- Joined

- Oct 24, 2010

- Messages

- 113

- Reaction score

- 32

Methylated spirits is the same as denatured alcohol.What kind of alcohol? There are 3 common ones, methyl, isopropanol and ethanol. Each has different burn characteristics.

Considering you got yours from a drug store I assume its isopropanol.

Cheers,

Andrew in Melbourne

The 99% alcohol is isopropyl alcohol. 500 ml (about half a quart) cost me $5.60. My engine doesn't run. Tried it with pre heating the cylinder---tried it with various amounts of flame, tried it rotating the opposite direction of rotation, tried it with a propane torch. The crankshaft is on dry ball bearings with no seals nor shields. Pivot point on beam has been oiled. Engine spins very easily by hand. I may try an aluminum piston instead of graphite. I'm kind of at a loss right now. The only part of this engine made more or less by guesswork is the cam. I am just using a copy of the cam used in my Senft "poppin" engine.

Similar threads

- Replies

- 413

- Views

- 40K

- Replies

- 61

- Views

- 8K

- Replies

- 4

- Views

- 520

Latest posts

-

-

-

-

For Sale 1/3 Scale Galloway Hit and Miss Casting Kit

- Latest: hopperwhistle

-

-

For Sale Coles American LaFrance Steam Fire Pumper Project

- Latest: hopperwhistle

-

For Sale Perkins Vertical Side Shaft Casting kit

- Latest: hopperwhistle

-

-

For Sale Coles Models Horizontal Gas Engine Casting Kit

- Latest: hopperwhistle