You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Model Sawmill Dreaming---

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

johnmcc69--You're right. I am a madman. And I've been this way most of my life.

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

OK re read, Got mixed up looking at the line for the no power feed on the mill, guess thats what i get for just scanning the pictures LOL.

Hopefully you under stood me with what I was talking about on the power feed not being able to move forward until the load is off the blade, probably by holding up the paw somehow until the load is off the blade. I probably should just keep my mouth shut and go back to lurking.....

Hopefully you under stood me with what I was talking about on the power feed not being able to move forward until the load is off the blade, probably by holding up the paw somehow until the load is off the blade. I probably should just keep my mouth shut and go back to lurking.....

What about if just the blade were tilted or actually tapered, think of it like a keyway broach.

Talking full size if the blade were 3/8 narrower at the bottom then by the time it reached the bottom of the stroke it would have cut 3/8" into the wood. As soon as the blade starts to rise the cutting edge will move away from the sawn timber allowing the log to be advanced by not more than 3/8" ready for the next stroke, just like putting a shim into the broaching bush.

The easiest way to do this on the model would be to just offset the top and bottom mountings by your "taper length" either the actual blocks or the holes in the blade

Talking full size if the blade were 3/8 narrower at the bottom then by the time it reached the bottom of the stroke it would have cut 3/8" into the wood. As soon as the blade starts to rise the cutting edge will move away from the sawn timber allowing the log to be advanced by not more than 3/8" ready for the next stroke, just like putting a shim into the broaching bush.

The easiest way to do this on the model would be to just offset the top and bottom mountings by your "taper length" either the actual blocks or the holes in the blade

I think your on to something jasonb. I just found this video that shows the blade motion like you mentioned.

http://www.steinkjer-kommune.net/eggevandring/egge/index.php?meny=23

http://www.steinkjer-kommune.net/eggevandring/egge/index.php?meny=23

Cogsy

Well-Known Member

I just found this video that shows the blade motion like you mentioned.

http://www.steinkjer-kommune.net/eggevandring/egge/index.php?meny=23

What an awesome piece of machinery. The reversing procedure, even pulling up the next log, simple, economical and ingenious design.

Thanks--Great video. I see what you mean about shaping the saw like a broach.---brian

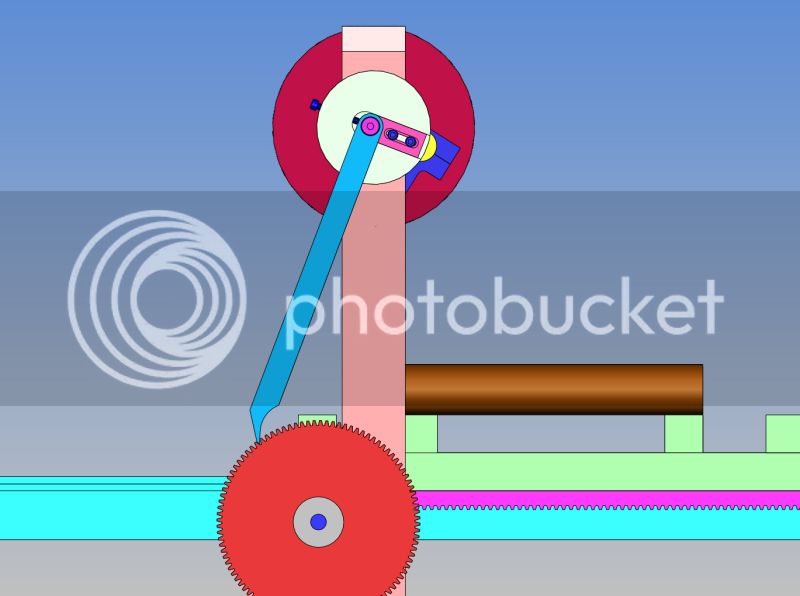

So there we have it. The inner and outer frames are completed except for some cosmetic work. The inner saw frame slides up and down quite nicely between the two outer columns. (Thats not a saw blade in there---its my 6" machinists ruler----It just fits!!!)

Bastelmike

Well-Known Member

- Joined

- Sep 12, 2012

- Messages

- 70

- Reaction score

- 6

Hello Brian,

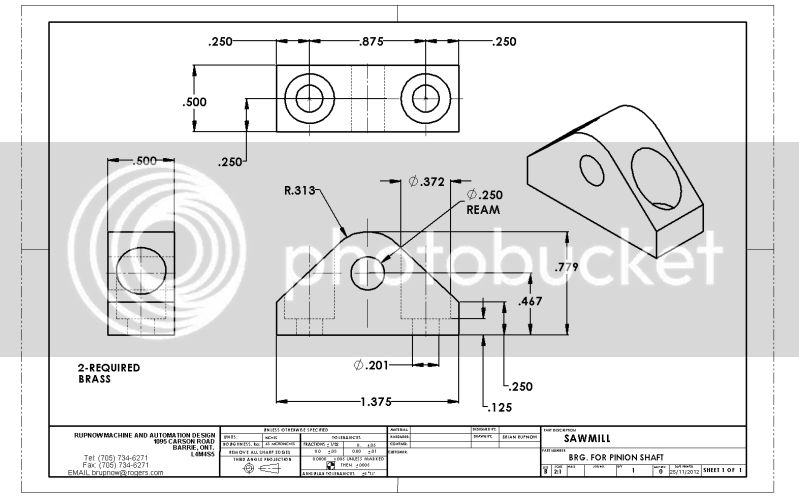

excellent CAD-work ! And perfect 2D-drawings, You are really a professional !

One concern I have is using a standard gear profile for the ratchet. All ratchet drives have a special non-symmetric profile for the teeth to prevent the ratchet from slipping out to early (during the forward movement), hope the picture will clarify this.

But the rounded profile of the gears will make this possible, depending on the angles of force during the stroke.

Mike

excellent CAD-work ! And perfect 2D-drawings, You are really a professional !

One concern I have is using a standard gear profile for the ratchet. All ratchet drives have a special non-symmetric profile for the teeth to prevent the ratchet from slipping out to early (during the forward movement), hope the picture will clarify this.

But the rounded profile of the gears will make this possible, depending on the angles of force during the stroke.

Mike

What an awesome piece of machinery. The reversing procedure, even pulling up the next log, simple, economical and ingenious design.

That second water wheel for reverse is a great idea. Someone put a lot of thought into getting the most out of water power on that one.

Bastelmike---It all depends on the angle of the dangle!!

Last edited:

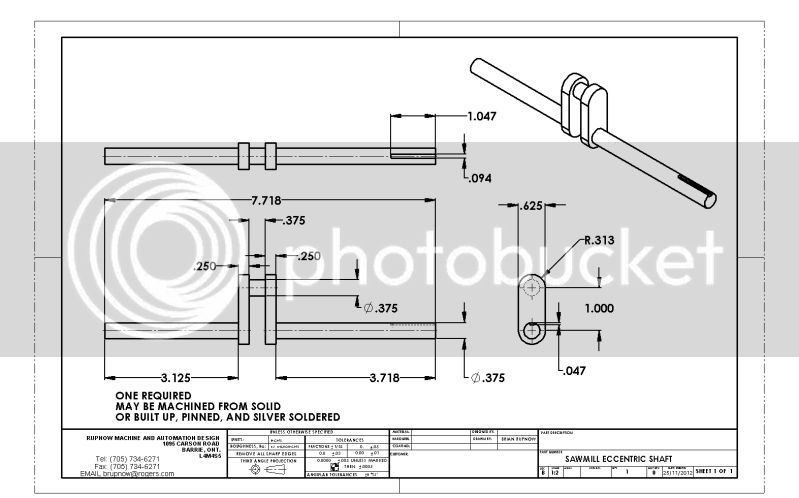

Here is the "eccentric shaft" made from 4 built up peices. Everything is positioned correctly, with a 3/8" square spacer between the "webs" and all joints drilled and reamed for .093" cold rolled "pins", cut from.093 cold rolled rod. After silver soldering, I will cut the longest shaft out between the webs, thus giving a "true" shaft with the correct offset to the "throw" journal. This is the way I build most crankshafts for model engines.

Last edited:

And here we have the finished eccentric shaft---All silver soldered, cut out, and ready to rock and roll!!! The con rod journal hasn't been polished, but since none of the siilver solder migrated onto it, thats okay. I will polish it later.

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

How far will the log advance per crankshaft revolution??

I don't know. That is why I have an adjustable eccentric . By dialing in the adjustable eccentric , I can set how much the log advances with each downstroke of the saw. The carriage sets still and doesn't advance at all when the saw is on the upstroke.It only advances on the downstroke of the sawblade and I am the guy that determines how much. Obviously, too much and it will stall the engine I have driving it. I would LIKE to think I could advance it about .030" each stroke, but I really don't know.

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

.030 sounds like alot per stroke IMHO. If it doesnt cut the full depth for the amount of advance it could get ugly. Maybe try the blade out in a coping saw to get a feel for the blade pressure and the depth of cut?

Well, now I know why I've been feeling so CRANKY all day.-----Groan----

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

Looks great!!! Would also make for a good interrogation device. I'll leave it up to everyone's imagination as to what parts of the body could be feed into it for best results lol

Similar threads

- Replies

- 61

- Views

- 8K