ERIC

How about i do some drawings for them instead

they just about drove me nuts making them

they truly are a pain in the butt and a great way to go bald tearing your hair out

theres a guy tel put me onto who gets similar made by the 50 lot!!

wish i knew that a year and a half ago

but they are not complex

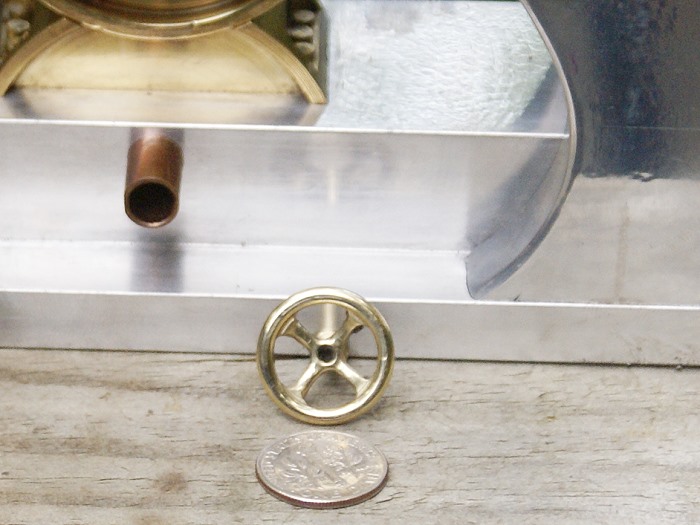

its a tube matched to a delrin C ( heat proof delrin)elliptical ball bearing with a spring and pivot

the spring is the hardest to get right and is tungsten alloy

the pivot leg (brass) sits in the centre of the spring and when the pressure pushed the ball bearing up the tube it pushes the pivot leg up too and moves the scale arm

once it gets past a certain point the shaft has a cone shape to allow the pressure out past the ball bearing and out the back of the guage ( the requirement was for a pressure release incorporated into the guage at 85 PSI and this was the simplest way i could figure it)

i got wedderburn scales to make the spring for me in the end and i had them make a 6" coil of it and i just cut it to length, and tested it and adjusted the length to match, i have a few inches left if you want some

but again as for making them theres about 10-30 hours work in each one from scratch nothing hard just awful fiddly and easy to bend, cut short, get glue in the wrong place etc

E & J winter sell em for 1/10th what i would charge i dunno how chinese folks must live on air

but yeah will dig up the drawings and make them work for uploading

i'll get a couple of machines out and maybe then if i feel i've been very bad i'll make one but only if i feel i've been very bad and need punishing

jack