Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Steve,

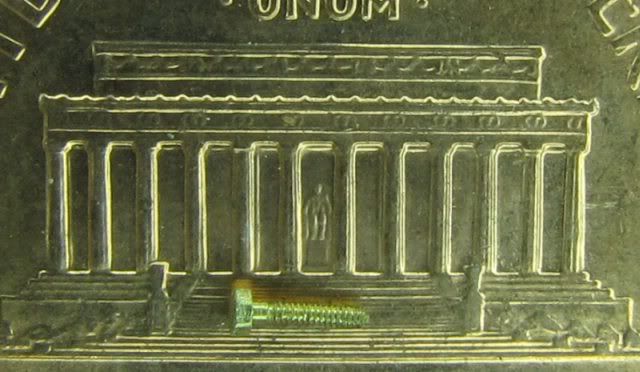

I'm interested in the relative sizes of the two engines in your photo...the one sitting on the coin and the one to its right. Thanks, and I am amazed by those who can work on this scale. I unfortunately must go in the other direction, ie, making the big parts ;D

Cheers,

Phil

I'm interested in the relative sizes of the two engines in your photo...the one sitting on the coin and the one to its right. Thanks, and I am amazed by those who can work on this scale. I unfortunately must go in the other direction, ie, making the big parts ;D

Cheers,

Phil