I grew up around trains, as the main line of the Chicago, Burlington, & Quincy (now BNSF) divided our community west of Chicago in half north-to-south, all 3 tracks of it! It was unusual to drive somewhere, and needing to cross those tracks, to not be stopped by a train, freight or passenger, half the time. Diesels were already in general use- (I'm not THAT old!)-, but steamers were common enough to be seen around 1950 or so, especially doing switching service in the small yards near my Grandma's house in Chicago, to which yards my Dad often took me walking of a still-light summer evening. The RR men did not seem to mind our presence, though technically we were trespassing, a fact lost to me, of course, as a kid.

So, while a senior in high school, the Burlington offered a steam excursion trip early in September, 1959, and my friends convinced me it would be a neat thing to do; I was still "chicken" yet, even though new stuff like girls were amazingly interesting-looking! A couple of the guys were older, had taken earlier trips, and got us to "hole up" in the first car behind the second locomotive (there were 2, a "double-header"), a Railway Express Agency (later REA) baggage car, with big square doors open, with 2X6s nailed across the openings, we were still able to hang out over them!

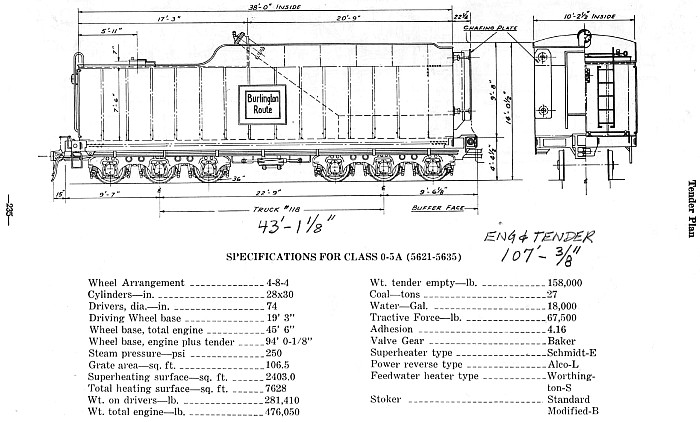

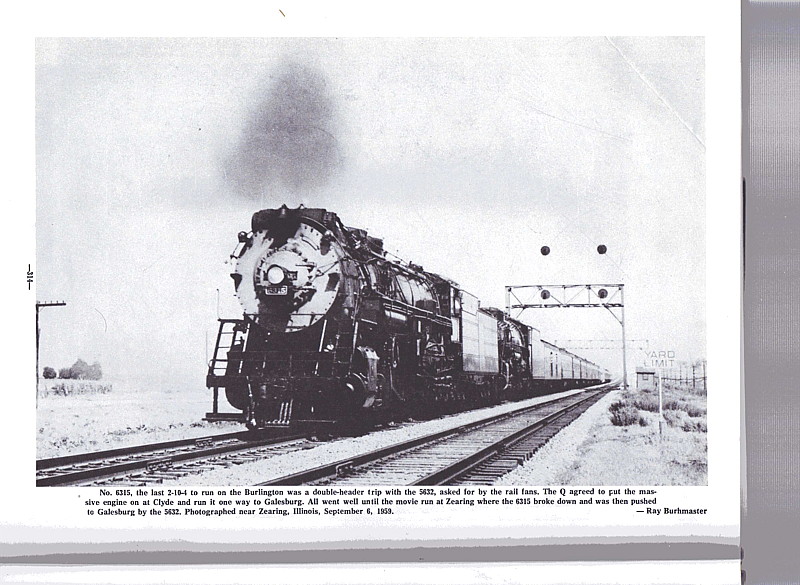

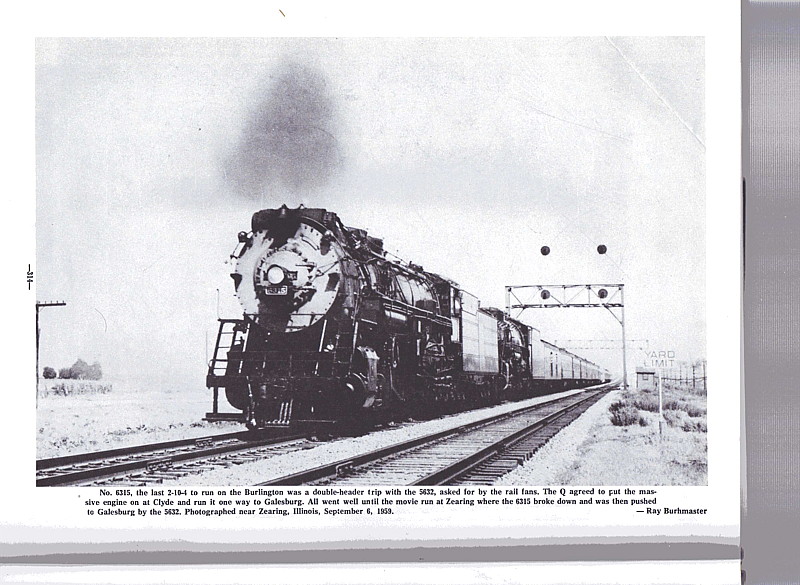

The head loco was a big Texas 2-10-4, No. 6315, the second a Northern 4-8-4, No. 5632. The trip was great, until everything ground to a halt; 6315 had broken it's eccentric rod, on the right side. This is the rod which drives the valve mechanism. I distinctly recall standing right next to the broken dangling pieces, astounded that the rod was easily as fat as my forearm! With much wheel-spinning and effort, 5632 managed to get 6315, ahead of it, to move forward, as it pushed the disabled beast to the nearest siding, where it was uncoupled, and left behind. The remainder of the trip went fine, with 5632 doing the work most easily.

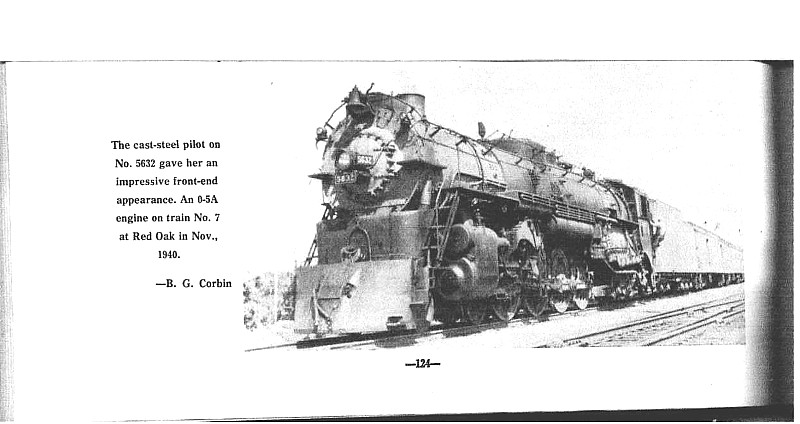

The pic below was taken by some fan and wound up found by me in a book about Burlington locomotives which I bought many years later. As I think about it now, it seems almost impossible that as that picture was taken in September, 1959, I was IN the baggage car which can be seen behind the 2nd. locomotive!

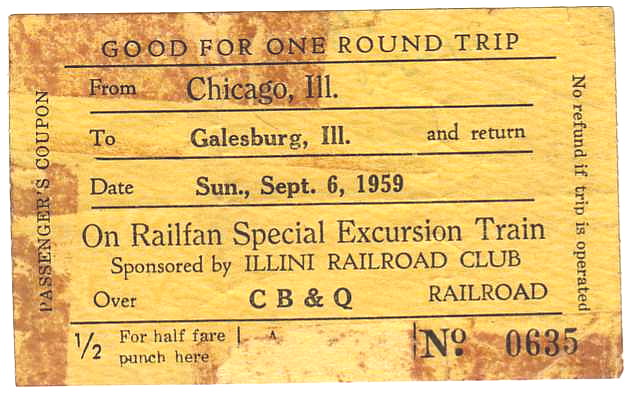

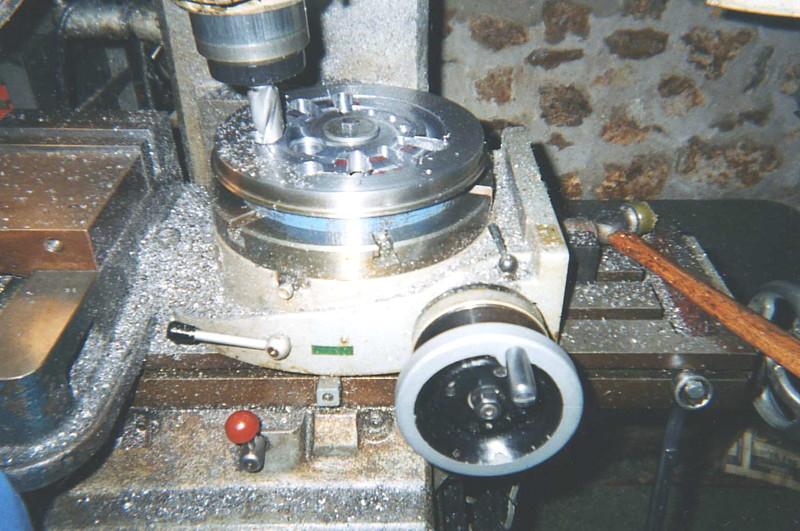

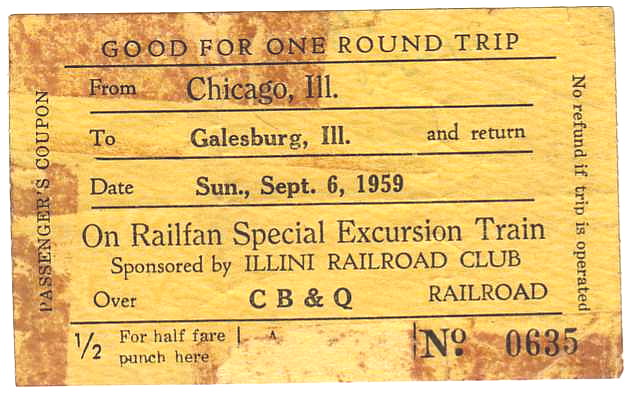

Also years later, I discovered the original ticket I had bought for the trip, tucked away in papers my Mother had saved and stored away; I wished I could thank her, but she was gone by then...if the dates are legible, note the book's author's accuracy, as they match! It was after that trip that I knew, someday, I would attempt to build a live steam locomotive, large enough to allow me to ride behind it on a car it pulled. I knew it would have to be a model of 5632! Thanks for reading; I will have more coming up. jack

So, while a senior in high school, the Burlington offered a steam excursion trip early in September, 1959, and my friends convinced me it would be a neat thing to do; I was still "chicken" yet, even though new stuff like girls were amazingly interesting-looking! A couple of the guys were older, had taken earlier trips, and got us to "hole up" in the first car behind the second locomotive (there were 2, a "double-header"), a Railway Express Agency (later REA) baggage car, with big square doors open, with 2X6s nailed across the openings, we were still able to hang out over them!

The head loco was a big Texas 2-10-4, No. 6315, the second a Northern 4-8-4, No. 5632. The trip was great, until everything ground to a halt; 6315 had broken it's eccentric rod, on the right side. This is the rod which drives the valve mechanism. I distinctly recall standing right next to the broken dangling pieces, astounded that the rod was easily as fat as my forearm! With much wheel-spinning and effort, 5632 managed to get 6315, ahead of it, to move forward, as it pushed the disabled beast to the nearest siding, where it was uncoupled, and left behind. The remainder of the trip went fine, with 5632 doing the work most easily.

The pic below was taken by some fan and wound up found by me in a book about Burlington locomotives which I bought many years later. As I think about it now, it seems almost impossible that as that picture was taken in September, 1959, I was IN the baggage car which can be seen behind the 2nd. locomotive!

Also years later, I discovered the original ticket I had bought for the trip, tucked away in papers my Mother had saved and stored away; I wished I could thank her, but she was gone by then...if the dates are legible, note the book's author's accuracy, as they match! It was after that trip that I knew, someday, I would attempt to build a live steam locomotive, large enough to allow me to ride behind it on a car it pulled. I knew it would have to be a model of 5632! Thanks for reading; I will have more coming up. jack